Roll Temporary Replacement Device for Continuous Rolling Mill

A technology of rolls and units, applied in the field of temporary replacement devices for rolls, which can solve the problems that the rolling mills cannot be connected smoothly and the continuous operation of the production line cannot be guaranteed, so as to achieve the effects of ensuring surface quality, reasonable structural design, and reducing roll consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

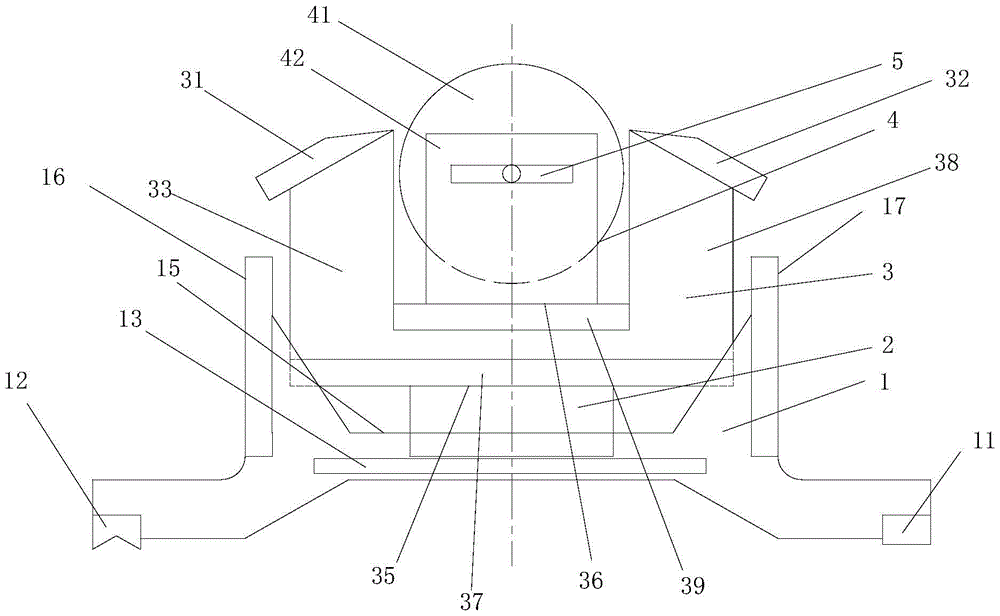

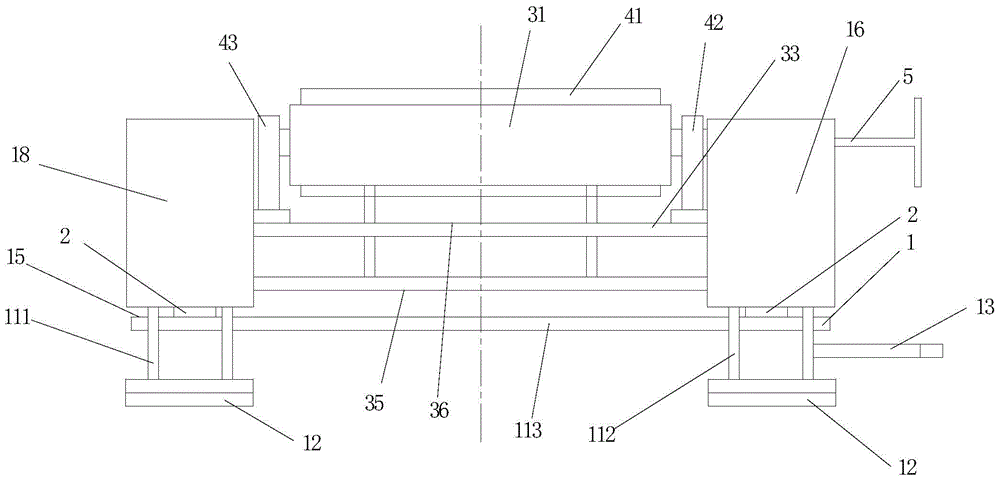

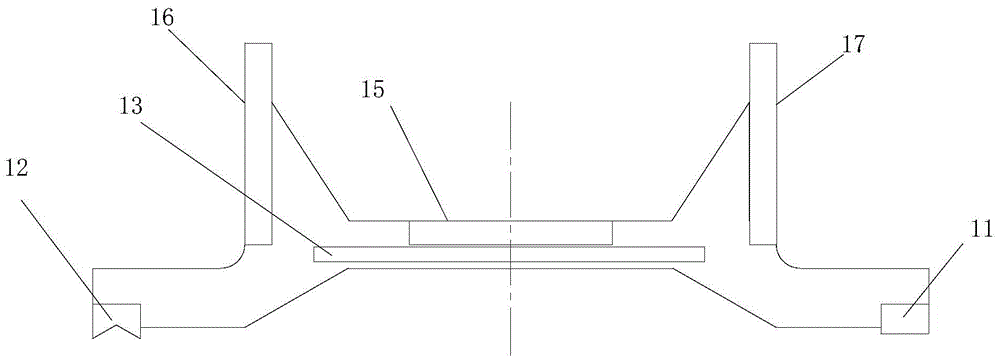

[0033] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0034] like Figure 1-8 As shown, a temporary replacement device for rolls of a continuous rolling mill, including a lower roller bed 1, an upper guide frame 3, and a roller assembly 4, the lower roll table 1 is connected to the lower part of the upper guide frame 3, and the upper guide frame The upper part of 3 is connected with the roller assembly 4. The lower roller bed 1 includes a transmission side base 111 and an operation side base 112. The transmission side base 111 and the operation side base 112 are connected by a steel plate 113. The operation side base 112 has an entrance plane 16 , The width dimension between the outlet plane 17 of the operating side base is consistent with the width dimension of the bearing housing on the operating side of the lower work roll of the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com