Piston lubricating system for concrete cylinder, control method and device thereof, and pumping equipment

A concrete cylinder and piston lubrication technology, which is applied to the components, mechanical equipment, pump elements, etc. of the pumping device for elastic fluid, can solve the problem that the two-line lubricating oil distributor cannot work normally, increase the risk of wear of the concrete cylinder, Unable to lubricate the piston of the concrete cylinder, etc., to ensure the smooth lubrication of the piston, reduce the risk of wear, and prevent blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

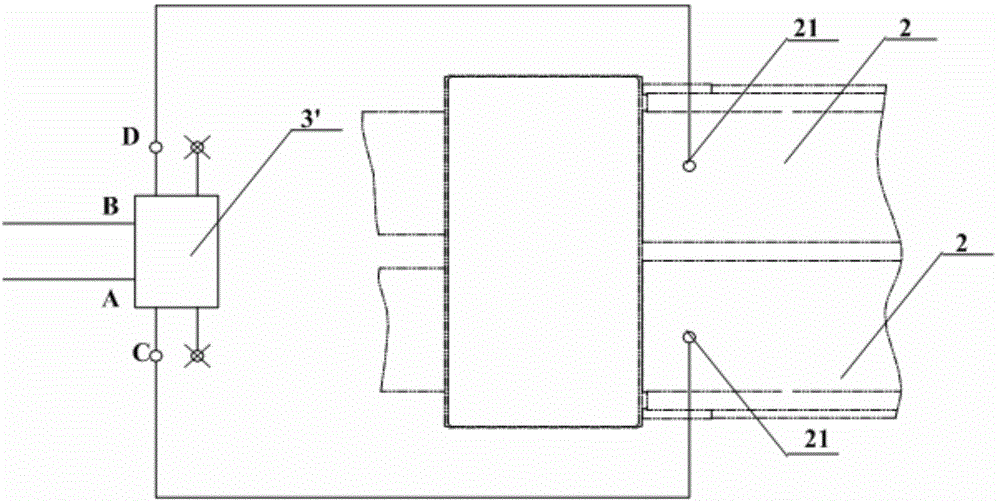

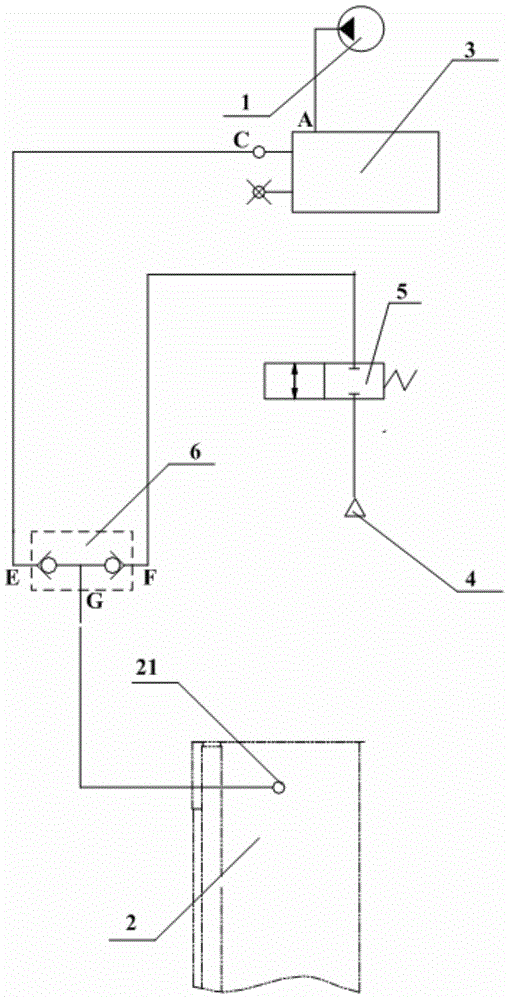

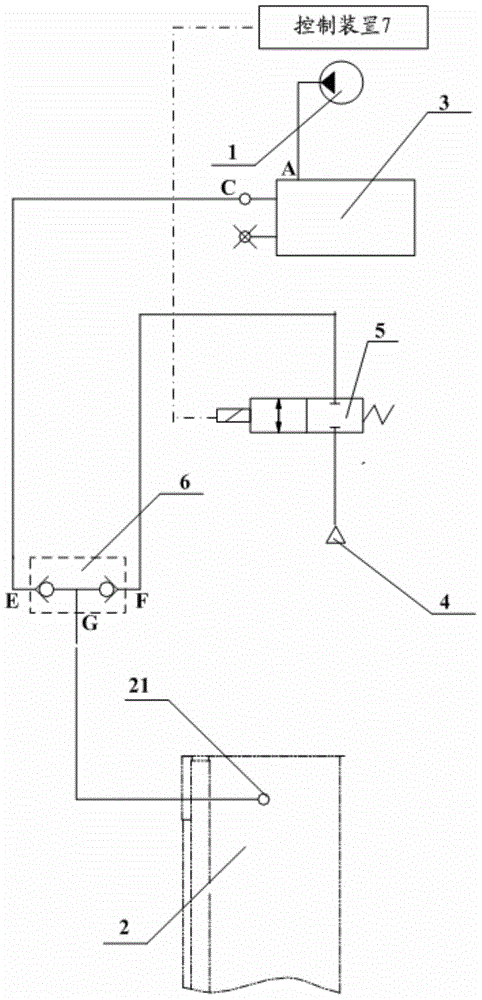

[0066] In order to prevent the blockage of the lubrication pipeline of the piston lubrication system of the concrete cylinder, thereby reducing the wear risk of the concrete cylinder, the embodiment of the present invention provides a piston lubrication system of the concrete cylinder, its control method, device and pumping equipment. In this technical solution, the piston lubrication system includes: an air source, a pressure-controlled on-off valve and an on-off valve. When the on-off valve is turned on, the gas from the air source enters the lubricating hole through the pressure-controlled on-off valve to flush the lubricating pipeline with gas. In this way, the blockage of the lubrication pipe and the lubrication hole is prevented, and the smooth lubrication of the piston of the concrete cylinder is guaranteed, thereby reducing the risk of wear of the concrete cylinder. In order to make the purpose, technical solution and advantages of the present invention clearer, the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com