Quick connection type power source base board fixing structure

A technology of power supply substrate and fixed structure, which is applied in the field of fast-connected power supply substrate fixed structure, can solve the problems of inconvenience, many required parts, and rising tapping cost, and achieves reduced man-hours, convenient production line operation, and satisfactory safety distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with embodiment the present invention is further described:

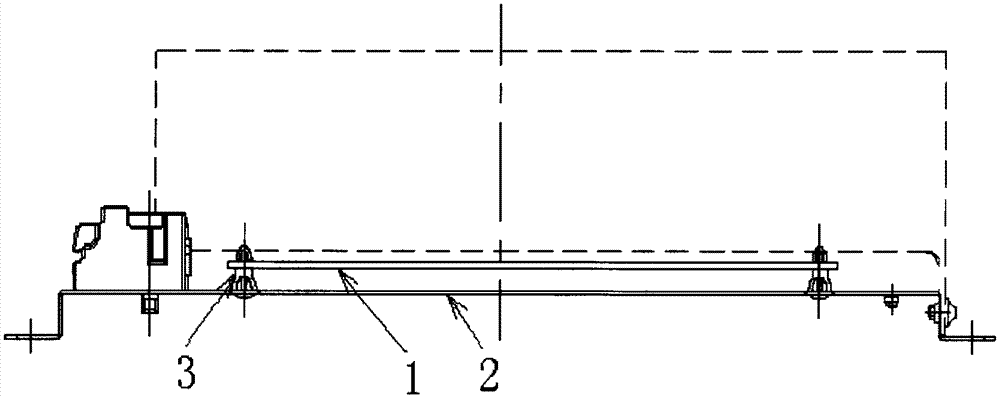

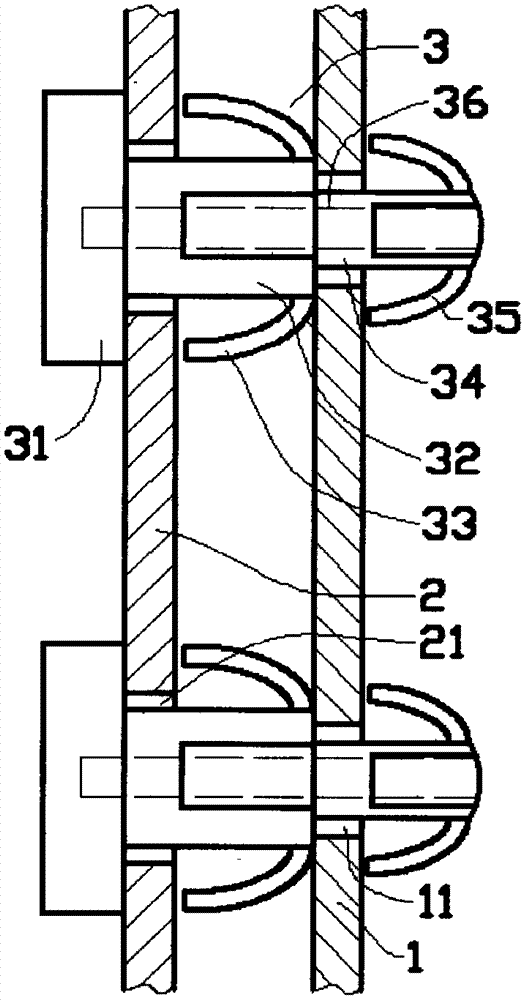

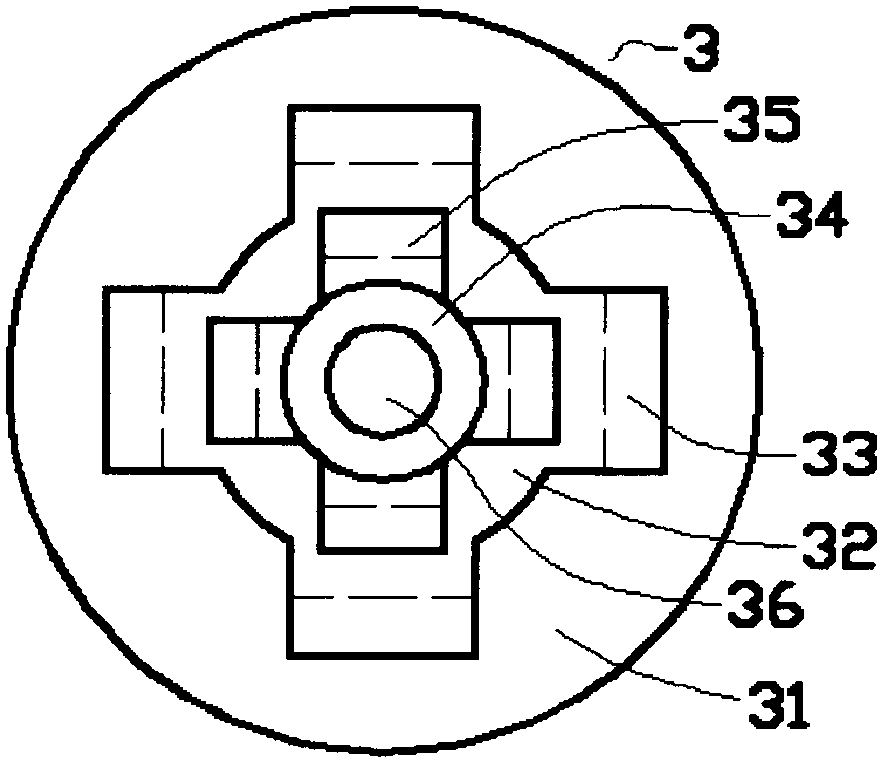

[0013] Such as figure 1 and figure 2 As shown in the embodiment, the quick-connect power supply substrate fixing structure includes a power supply substrate 1 and a power supply fixing plate 2; the power supply substrate 1 and the power supply fixing plate 2 are connected by a plastic buckle 3, and the plastic buckle 3 is designed with an indenter 31 at the end, and the inner side of the indenter 31 is designed with a spacer column 32, and the front end of the spacer column 32 stretches out a middle bar 33 bent towards the tail end, and the spacer column 32 The front end is designed with a top post 34 coaxial with the spacer post 32, and the front end of the top post 34 protrudes from a top bar 35 bent toward the tail end. The power base plate 1 and the power supply fixing plate 2 are respectively It is designed with an upper hole 11 and a lower hole 21. The diameter of the upper hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com