Pressure detection structure and touch device

A technology for detecting structures and touching equipment, applied in the direction of measuring force, measuring devices, instruments, etc., can solve problems affecting machine consistency, reducing product reliability, and large assembly tolerances, so as to improve test production efficiency and reduce tolerances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

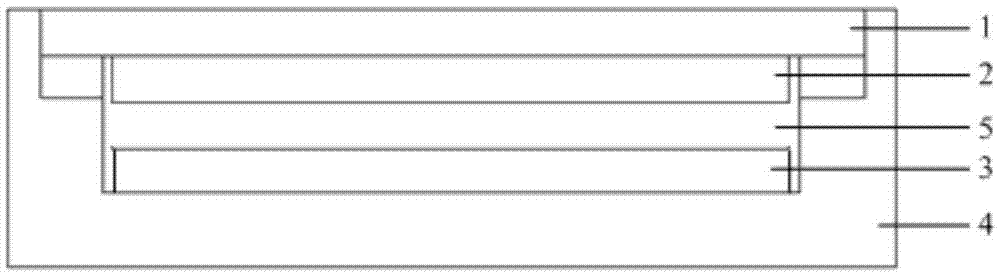

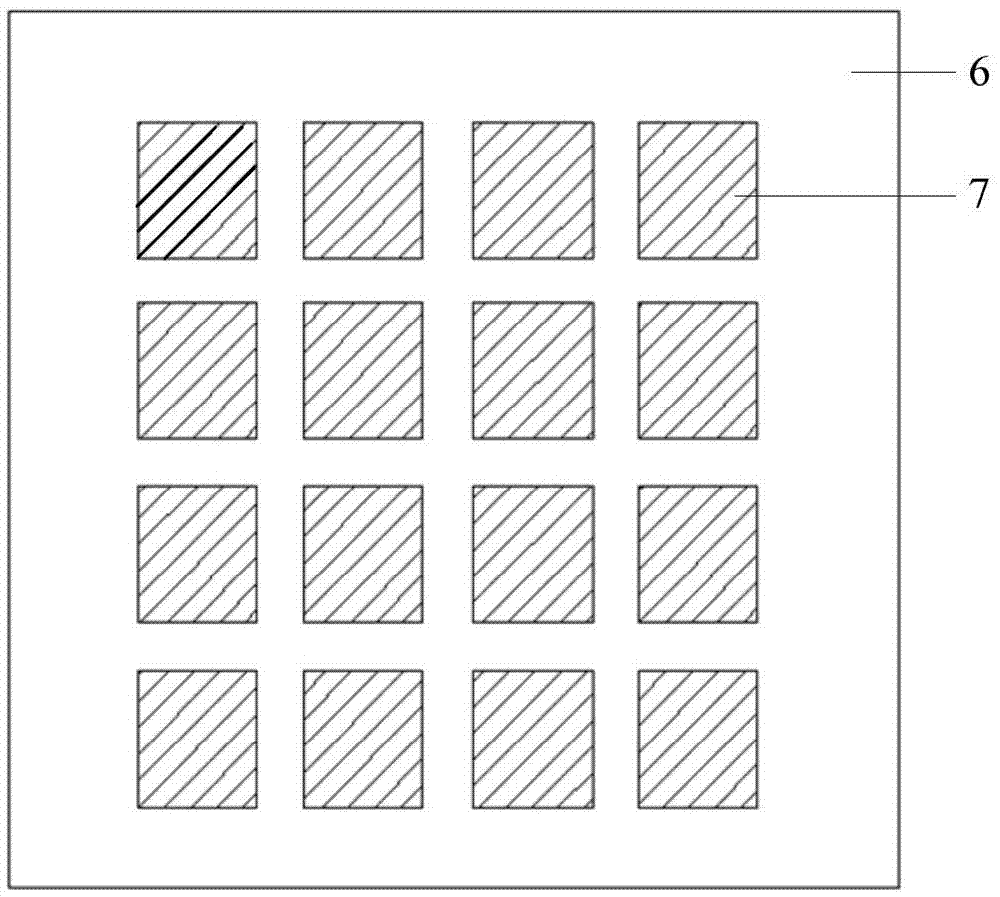

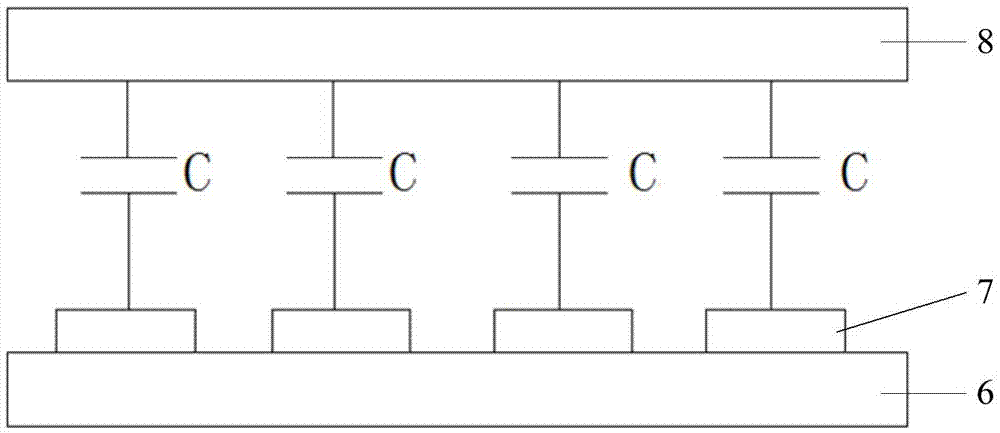

[0047] In the present invention, the pressure sensor is arranged inside the display device, and any conductive member or the conductive middle frame in the display device is used as a reference electrode. There is a variable gap between the pressure sensor and the reference electrode, and the pressure sensor outputs a pressure signal according to the capacitance change between its sensing electrode and the reference electrode. Therefore, it is avoided that the tolerance of the distance between the display module and the middle frame affects the consistency of pressure sensing between the touch devices, and the tolerance of the complete assembly of the touch devices is reduced. Moreover, during the mass production test, a single display device can be subjected to a stress test, and it is not necessary to cooperate the display device with the middle frame to perform a stress test, which improves the test production efficiency.

[0048] Of course, implementing any technical solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com