Splicing screen and manufacturing method thereof and display device

A manufacturing method and splicing screen technology, which are applied in the field of display devices, splicing screens and their manufacturing methods, and can solve problems such as inability to achieve seamless splicing, liquid crystal leakage, and non-display areas of sub-display panels that cannot be completely eliminated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manner of the splicing screen provided by the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0042] The size and shape of each component in the drawings do not reflect the true proportion of the splicing screen and its manufacturing method, but are only intended to schematically illustrate the content of the present invention.

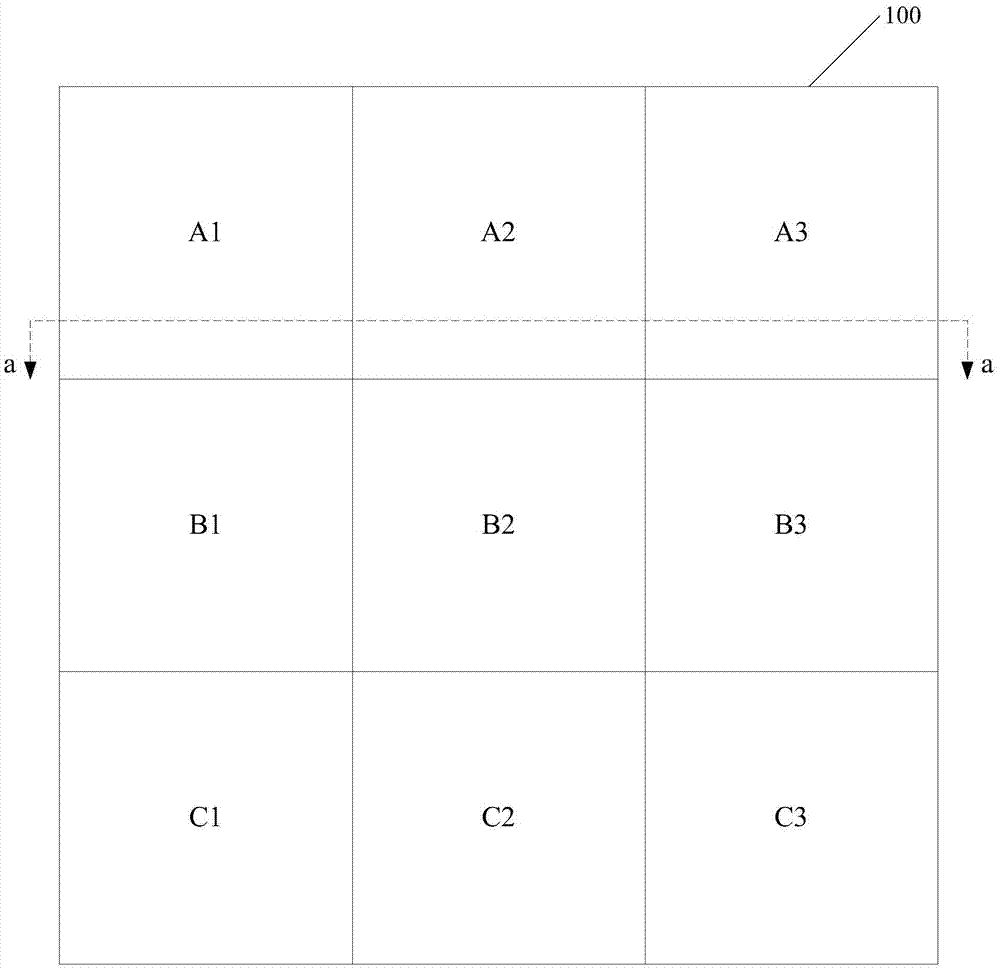

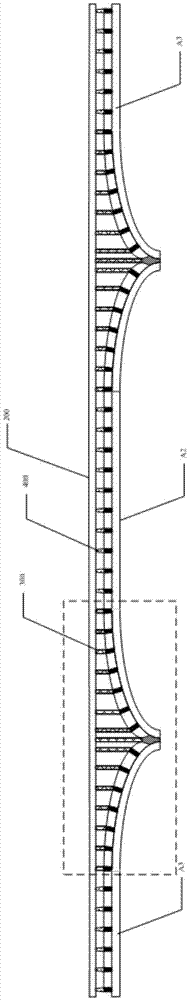

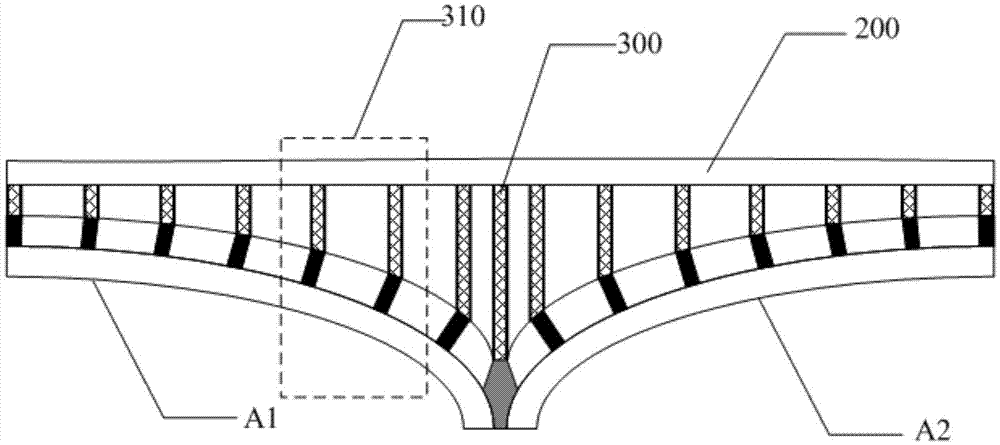

[0043] The embodiment of the present invention provides a splicing screen, such as figure 1 and 2 shown, including:

[0044] At least two mutually spliced display panels 100, each display panel 100 includes a curved area and a flat area where the side edge of the spliced place is bent toward the back of the display surface; figure 1 3*3 display panels 100 are spliced together to form a splicing screen as an example. figure 2 for figure 1 The side views of the display panels 100 numbered A1, A2, and A3 in the area aa, wherein the A1 displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com