MEMS microphone and formation method thereof

A microphone and diaphragm technology, applied in the field of MEMS, can solve the problems of low service life and poor performance of MEMS microphones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

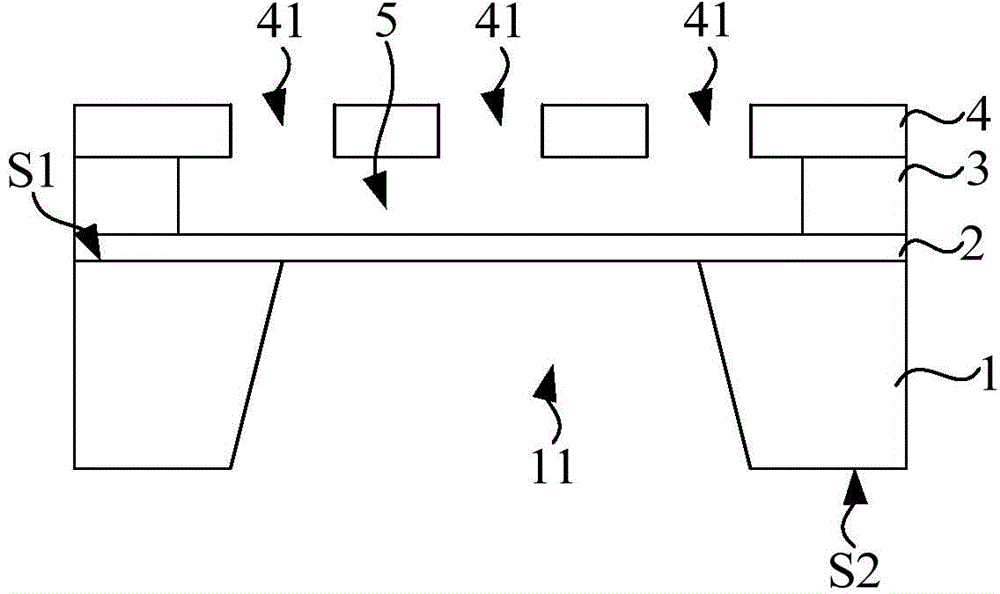

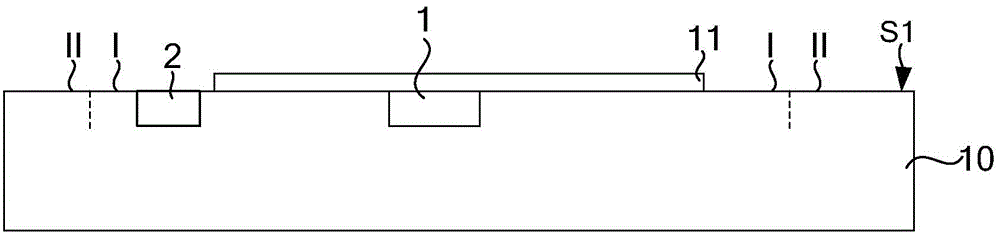

[0056] refer to image 3 , providing a first wafer 10, the front side S1 of the first wafer 10 has a first area I and a second area II, the second area II surrounds the first area I, and a conductive plate 11 is formed in the first area I. An integrated circuit (not shown in the figure) is formed in the first wafer 10 , the integrated circuit has a first electrode 1 and a second electrode 2 , wherein the conductive plate 11 is electrically connected to the first electrode 1 .

[0057] The conductive electrode plate 11 conducts electricity and will be used as the lower electrode plate of the MEMS microphone. In a specific embodiment, the material of the conductive plate 11 is Si, SiGe or Ge doped with ions, and may also be other metals suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com