Method for producing water-absorbing resin

A manufacturing method and water-absorbing technology, applied in the field of manufacturing water-absorbing resin, can solve the problems of material elution, poor chemical resistance, etc., and achieve the effect of continuous manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0231] [Example 1: Immersion Test 1 of Material]

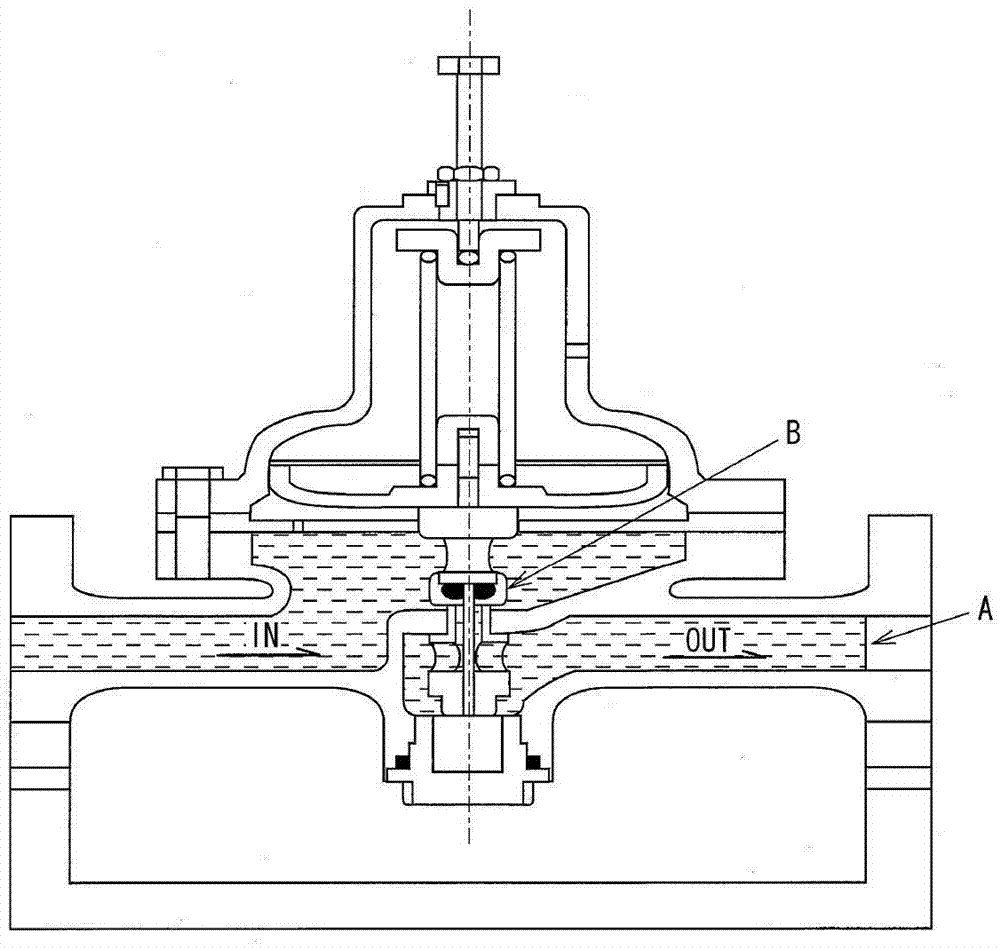

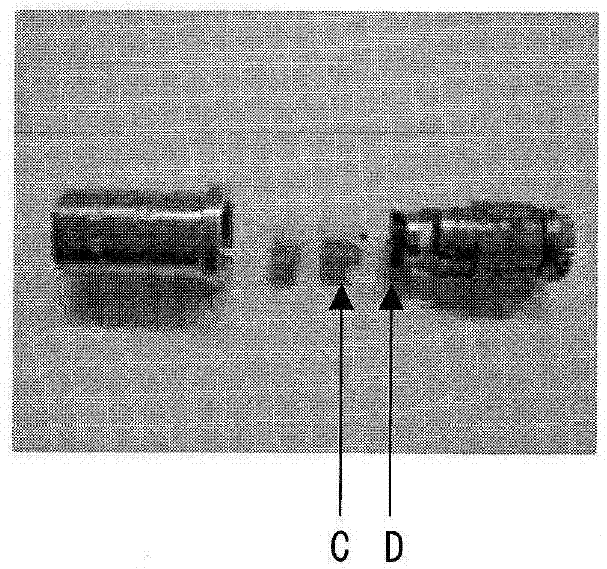

[0232] In the surface cross-linking agent used in the surface cross-linking process, the nozzle cushion whose main material is polytetrafluoroethylene (PTFE) (hollow cone nozzle K140 manufactured by IKEUCHI Co., Ltd. Parts) were impregnated at 30°C for 1 month. As the above-mentioned surface cross-linking agent, a surface cross-linking agent solution having the composition ratio of ethylene carbonate (EC):1,2-propylene glycol (PG):water (W)=0.5:0.5:3.0 was used.

[0233] The volume of the nozzle cushion before dipping in the above surface crosslinking agent is 93 [mm 3 ]. The volume of the nozzle cushion after dipping in the above surface crosslinking agent is 95 [mm 3 ]. The volume of the nozzle cushion increased by immersion in the surface cross-linking agent is 2 [mm 3 ], the volume change rate of the nozzle cushion is 2[%]. The results are shown in Table 1.

[0234] The nozzle cushion whose main material is PTFE doe...

Embodiment 2

[0235] [Example 2: Immersion test 2 of material]

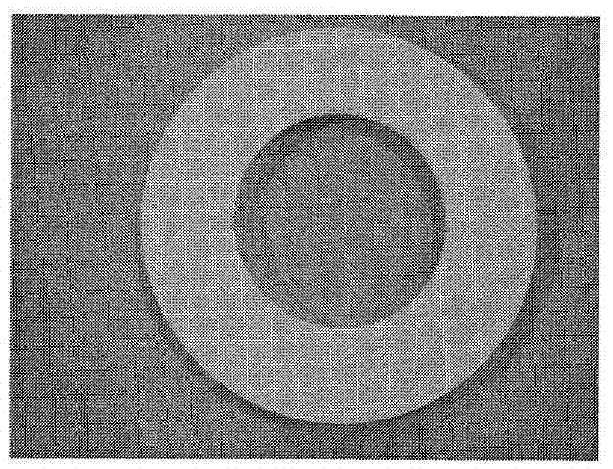

[0236] In the same surface cross-linking agent as in Example 1, immerse a closer made of ceramics (hollow cone nozzle K140 manufactured by IKEUCHI Co., Ltd. - a part in the mold of micro mist generation type extremely small spray volume) at 30°C for 1 month.

[0237] The volume of the closer before being immersed in the above-mentioned surface cross-linking agent is 97 [mm 3 ]. The volume of the closer impregnated with the above-mentioned surface cross-linking agent is 99 [mm 3 ]. The volume of the closure increased by immersion in the surface cross-linking agent is 2 [mm 3 ], the volume change rate of the closer is 2[%]. The results are shown in Table 1.

[0238] The closure whose main material is ceramic does not easily change in volume even if it is immersed in the above-mentioned surface cross-linking agent, so it can be seen that it can be used for stably and continuously supplying the above-mentioned surface cross-...

Embodiment 3

[0243] [Example 3: Immersion test 3 of material]

[0244] In the surface cross-linking agent used in the surface cross-linking process, the main material of the nozzle cushion made of polytetrafluoroethylene (PTFE) (hollow cone nozzle K140 manufactured by IKEUCHI Co., Ltd. - micro mist generation type extremely small spray volume) Parts) impregnated at 30°C for 1 month. As above-mentioned surface cross-linking agent, used the surface cross-linking agent solution of following constituent ratio, namely: 1,4-butadiene (BD):1,2-propanediol (PG): water (W)=0.5:0.5: 3.0.

[0245] The volume of the nozzle cushion before being immersed in the above-mentioned surface cross-linking agent is 93 [mm 3 ]. The volume of the nozzle cushion soaked in the above surface crosslinking agent is 95 [mm 3 ]. The volume of the nozzle cushion increased by immersion in the surface cross-linking agent is 2[mm 3], the volume change rate of the nozzle cushion is 2[%]. The results are shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap