A soil dispensing device for combine machine

A technology for a combined working machine and a distribution device, which is applied in agricultural machinery and implements, applications, agriculture, etc., can solve the problems of complex structure design, high replacement cost, inconvenient maintenance, etc., and achieves low maintenance and replacement costs and simple structure. , to satisfy the effect of the diversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

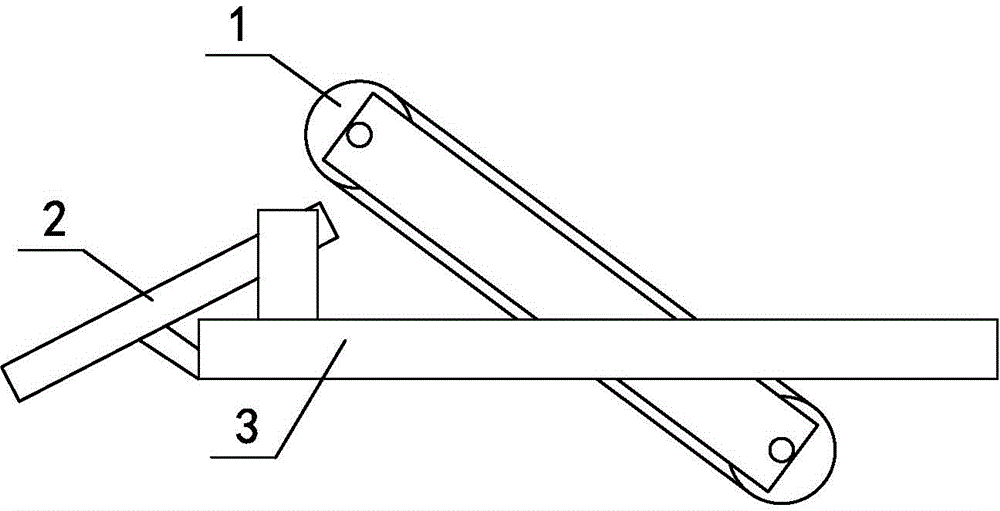

[0015] Such as figure 1 , figure 2 As shown, the soil distribution device for the combined operation machine includes a frame 3 and a conveyor 1 for conveying soil. The upper left end is installed on the frame 3 with a diverter tank 2 for diverting the soil, which is low in the left and high in the right. The diverter tank 2 is located on the left side of the conveyor 1. The depth of the diverter tank 2 is 50 mm, the width of the tank is 200 mm, and the length of the tank is 1500mm.

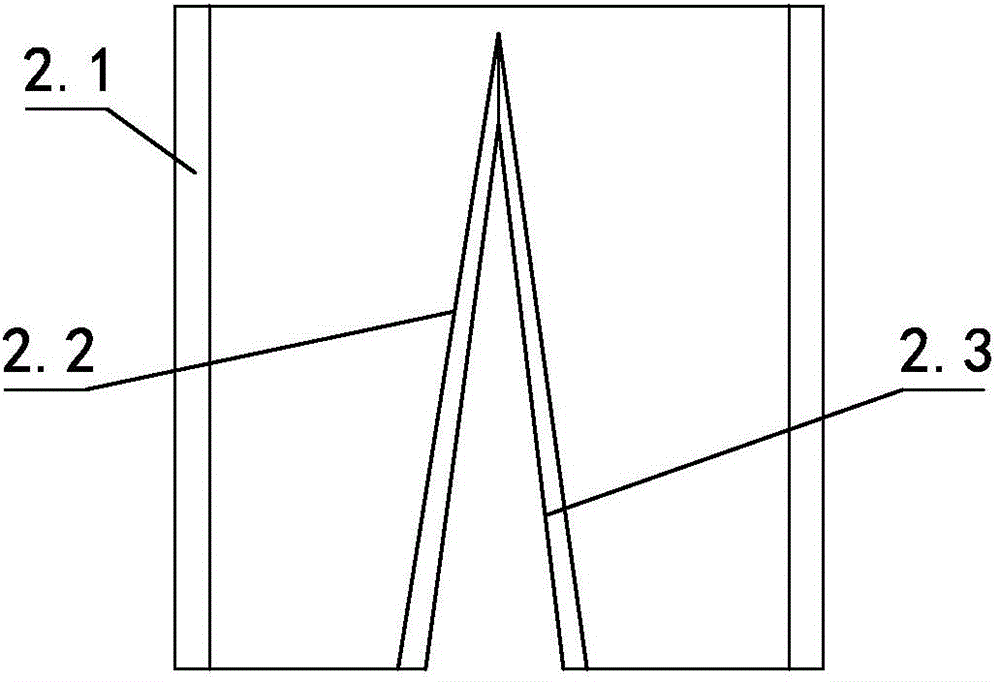

[0016] In this embodiment, the splitter tank 2 includes a tank body 2.1, a left splitter plate 2.2 and a right splitter plate 2.3 are arranged in the middle of the longitudinal direction of the tank body 2.1, and a left splitter plate 2.2 and a right splitter plate at the soil inlet of the splitter tank 2 are arranged. The splitter plates 2.3 are connected together, and the left splitter plate 2.2 and the right splitter plate 2.3 at the outlet of the splitter tank 2 are separated to form a tri...

Embodiment 2

[0020] Changes are made on the basis of Embodiment 1, and the changes are as follows:

[0021] The groove depth of the splitter groove 2 is changed to 80mm, the groove width is changed to 300mm, and the groove length is changed to 3000mm; the distance between the left splitter plate 2.2 and the right splitter plate 2.3 is changed to 50mm. Others are the same as embodiment one.

Embodiment 3

[0023] The groove depth of the splitter groove 2 is changed to 60mm, the groove width is changed to 250mm, and the groove length is changed to 2000mm; the distance between the left splitter plate 2.2 and the right splitter plate 2.3 is changed to 40mm. Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Slot length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com