Entrainment flow control type supercritical extraction pharmaceutical equipment

A pharmaceutical equipment and supercritical technology, applied in solvent extraction, solid solvent extraction, chemical instruments and methods, etc., can solve the problems of low single-pass extraction rate, increased extraction cost, reduced extraction efficiency, etc., so as to improve the diffusion range and improve extraction efficiency. Efficiency and effect, the effect of efficient extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

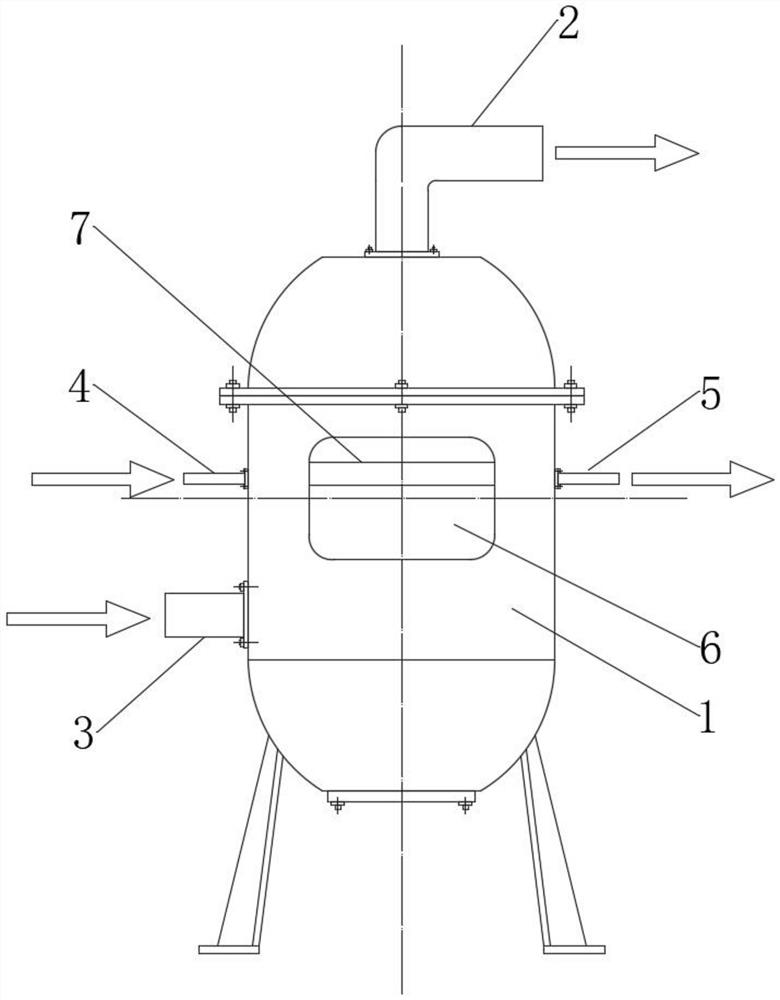

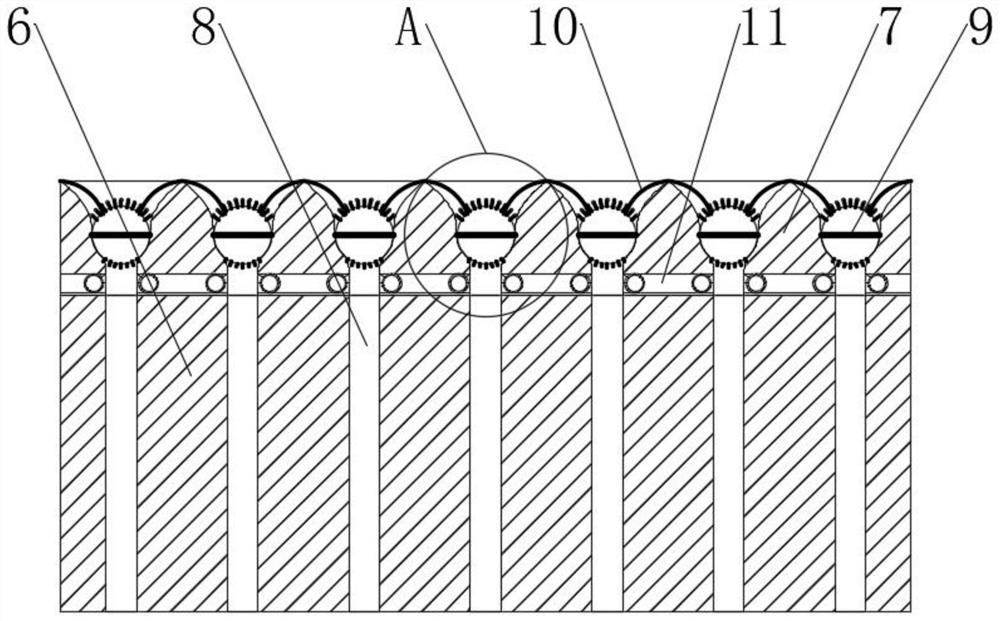

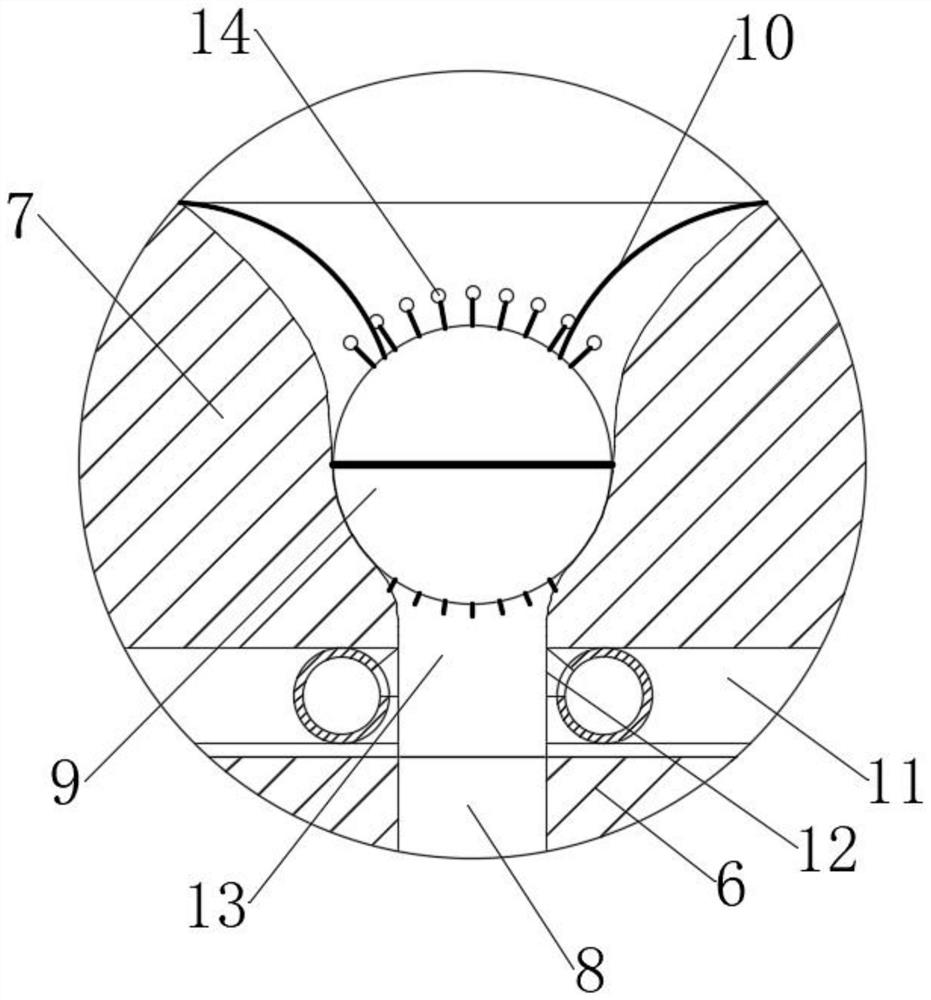

[0043] see Figure 1-2 , an entrainment flow control type supercritical extraction pharmaceutical equipment, comprising an extraction kettle 1, the upper and lower ends of the extraction kettle 1 are respectively connected with an output pipe 2 and an input pipe 3, a flow table 6 is installed in the extraction kettle 1, and the upper end of the flow table 6 is installed There is an extraction platform 7, the left and right ends of the extraction platform 7 are connected with a feed pipe 4 and a discharge pipe 5, a plurality of evenly distributed distribution vertical holes 8 are opened in the diversion platform 6, and a plurality of evenly distributed vertical holes 8 are opened on the extraction platform 7. Extraction holes 13, and the extraction holes 13 and the distribution vertical holes 8 correspond to each other, and the extraction table 7 is also inlaid with a mesh pipe 11, and the mesh pipe 11 is connected with the feed pipe 4 and the discharge pipe 5 respectively, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com