Forging method for unloading and temporary storage device-end flange

A flange and forging technology is applied in the field of fuel loading and unloading equipment, which can solve the problems of many forging processes, high manufacturing costs, and many times of fire, and achieve the effect of simple process, less times of fire, and avoiding the concave center of forgings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

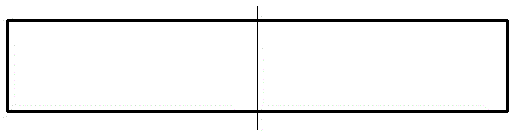

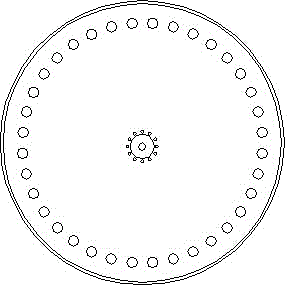

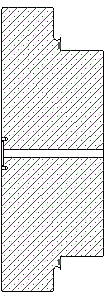

[0013] Such as figure 1 , 2 , 3, a kind of forging method of unloading temporary storage device-end flange, the specific steps are as follows: a. The upsetting round cake or steel ingot with smaller thickness and diameter-to-height ratio greater than 2.5 is sawed and cut into blank according to metal The fiber direction is parallel to the upper and lower wide flat anvils on the press; b. The flat anvil is in contact with the billet as a whole and drawn out, just like the upsetting operation, the steel billet is drawn from the initial thickness of 390mm to 1360mm long; c. The billet is returned to the furnace for heating, and upsetting to the size of the forging after being released from the furnace.

[0014] When the flat anvil is in contact with the blank as a whole, it is the same as the upsetting operation, and the deformation speed of the forging and the deformation of the first anvil are increased. Upsetting means that after the blank is heated, the axis of the blank is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com