Variable-position chuck sleeve

A chuck and variable technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of inconvenient, not easy to carry, easy to lose the sleeve components, install and replace, etc., and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

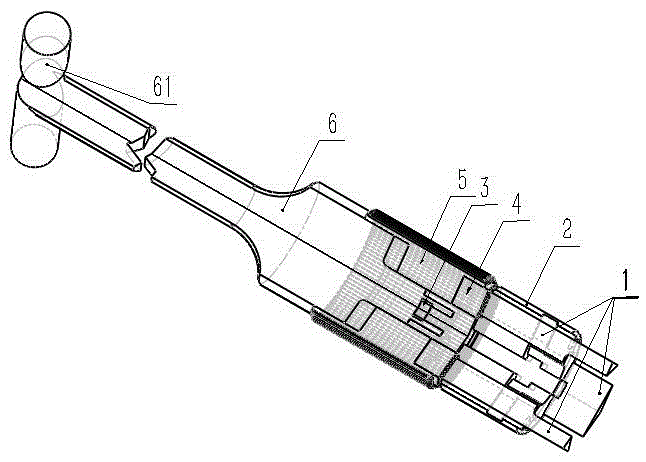

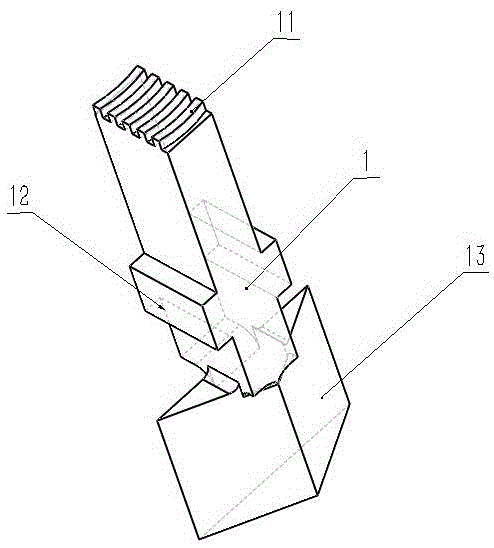

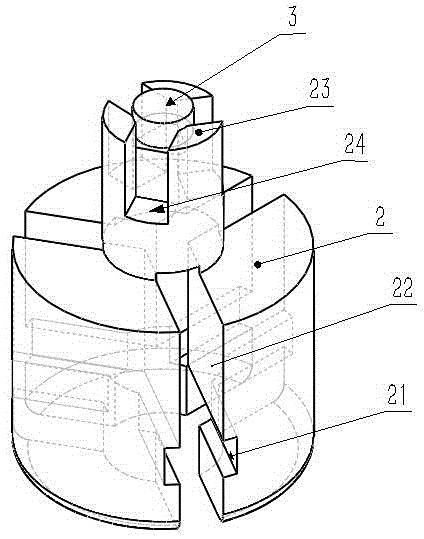

[0023] exist figure 1 Among them, the three claws 1 are respectively installed in the three claw grooves 22 of the chuck 2, and the angle between the two isosceles triangles of the cross-section of the claw head 13 on the claw 1 faces the outside of the chuck 2, and the claws The boss 12 on the side of 1 matches the groove 21 on the side of the claw groove 22 (that is, the boss 12 on the side of the claw 1 is located in the groove 21 on the side of the claw groove 22), so that the claw 1 can only move along the chuck 2 radially slides, the claw teeth 11 of the claw 1 expose the large end face of the chuck 2 ( image 3 upper large end surface), the upper end of the coil wire 4 ( Figure 5 or Figure 4 inverted) along the small shaft end of chuck 2 ( image 3 upper small end surface) so that the flat thread on the end surface of the coil wire 4 meshes with the claw teeth 11 on the end surface of the claw 1, the rotation of the coil wire 4 forces the three claws 1 to slide in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com