Caky gear clamping device

A clamping device and gear technology, applied in chucks, manipulators, program-controlled manipulators, etc., can solve the problems of inconvenient structure adjustment, reduced work efficiency, cumbersome operation process, etc., and achieve flexible structure of the grapple, convenient operation, and less The effect of small running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

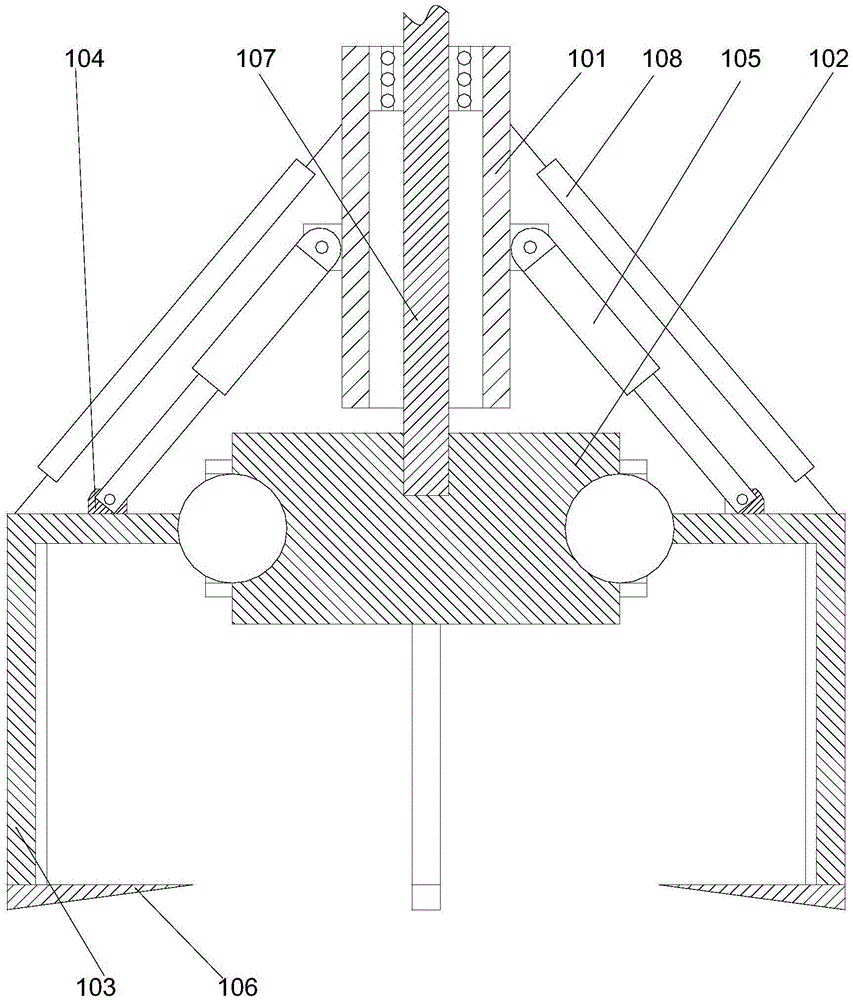

[0021] Such as figure 1 As shown, a pie-shaped gear clamping device includes a central shaft 101 and a fixed plate 102 that is arranged under the central shaft 101 and is a quadrangular prism. The grapple 103, the grapple 103 is vertically bent, one right-angled side of the grapple 103 is connected to the fixed plate 102, and the other right-angled side is around the side of the fixed plate 102, The grapples 103 are respectively connected with the spherical hinges of the fixed discs 102, flange structures 104 are respectively arranged on the upper end surfaces of the grapples 103, and four flange structures 104 are arranged on the side wall of the central axis 101 Hydraulic cylinders 105 arranged at equal intervals, one end of the four hydraulic cylinders 105 is hinged on the side wall of the central axis 101, and the other ends of the four hydraulic cylinders 105 are respectively hinged on the flange structure 104, the inside of the central axis 101 is a hollow structure, an...

Embodiment 2

[0024] In this embodiment, on the basis of Embodiment 1, in order to better fix the gear, in this embodiment, preferably, a locking portion 106 is respectively provided at the end of the grab hook 103 away from the central axis 101, so that The upper end surface of the clamping portion 106 is perpendicular to the right-angled side of the hook 103 away from the end of the central shaft 101 , and the ends of the clamping portion 106 point to the axial direction of the central shaft 101 . By providing the clamping part, the clamping part can be placed on the lower end surface of the gear, so that the clamping part can support the gear, and under the joint action of the inner wall of the grapple, the gear can be clamped conveniently.

[0025] In order to increase the relative friction between the engaging portion and the lower end surface of the gear, in this embodiment, preferably, an anti-slip emboss is provided on the upper end surface of the engaging portion 106, and the engagi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com