Plaster cutting packaging method and device

A technology of slice packaging and plaster packaging, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low production efficiency, many manual operations, and long import equipment cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

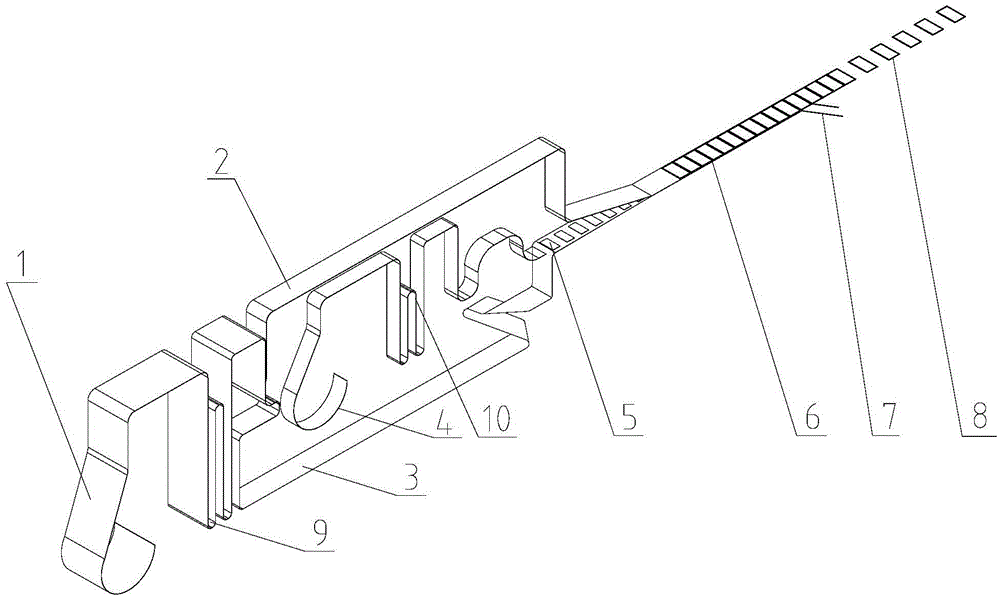

[0078] A kind of plaster slice packing method of present embodiment, as figure 1 shown, including the following steps:

[0079] (1) After the packaging film 1 is unrolled, the packaging film is cut to form an upper packaging film 2 and a lower packaging film 3 that are independent of each other; meanwhile, after the plaster material 4 is unrolled, it is cut into plaster sheets 5 to be packaged ;

[0080] (2) The lower packaging film is turned over by 180°, and then the upper packaging film, plaster sheet and lower packaging film arranged in sequence from top to bottom are simultaneously sent to the mold sealing device for sealing and packaging to form a continuous plaster package 6;

[0081] (3) Carry out trimming process to continuous plaster bag, excise unnecessary packaging film edge material 7;

[0082] (4) Carry out slitting to continuous plaster bag again, form independent plaster packet 8.

[0083] Wherein, in step (1), a packaging film storage section 9 is also pro...

Embodiment 2

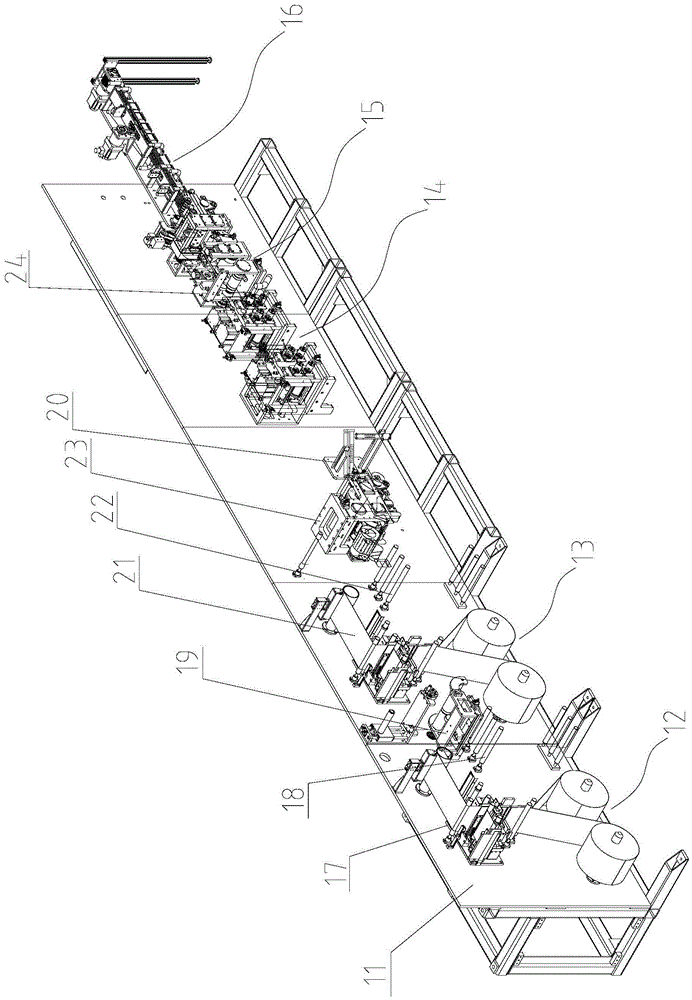

[0085] A kind of plaster slice packaging equipment for realizing the method described in embodiment 1 in this embodiment, such as figure 2 As shown, it includes packaging film unwinding and cutting device 12, plaster material unwinding and cutting device 13, mold sealing and pressing device 14, side material cutting device 15 and packet cutting and output device 16 respectively arranged on the frame 11. The outlet end of the packaging film unwinding and cutting device and the outlet end of the plaster material unwinding and cutting device are respectively connected to the inlet end of the mold sealing and pressing device. The delivery direction of the package is set in sequence; among them, the packaging film unwinding and cutting device cuts the packaging film to form an upper packaging film and a lower packaging film, and the plaster material unwinding and cutting device cuts the plaster material to form a plaster sheet, and the mold is sealed and pressed The device seals a...

Embodiment 3

[0125] A kind of plaster sheet packaging equipment of the present embodiment, compared with embodiment 1, its difference is:

[0126] In order to make the sealing position of the mold sealing device more accurate, a position detection mechanism can also be provided on the sealing roller group, such as Figure 13 or Figure 14 As shown, the position detection mechanism includes a detection roller (that is, the upper sealing pressure roller 14-1), a detection roller mounting plate 14-13 and a sensor 14-14, the cylindrical surface of the detection roller is provided with a groove 14-15, and the detection roller Mounting plates for detection rollers are respectively arranged at both ends, and sensors are arranged on one side of each detection roller mounting plate; The upper packaging film, the plaster sheet and the lower packaging film pass through the gap between the upper sealing pressure roller and the lower sealing pressure roller at the same time. The upper and lower packag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com