Intelligent plant light filling lamp

A fill light, LED fill light technology, applied in botanical equipment and methods, light sources, electric light sources, etc., can solve the problem of low degree of automation, and achieve the effect of overcoming low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

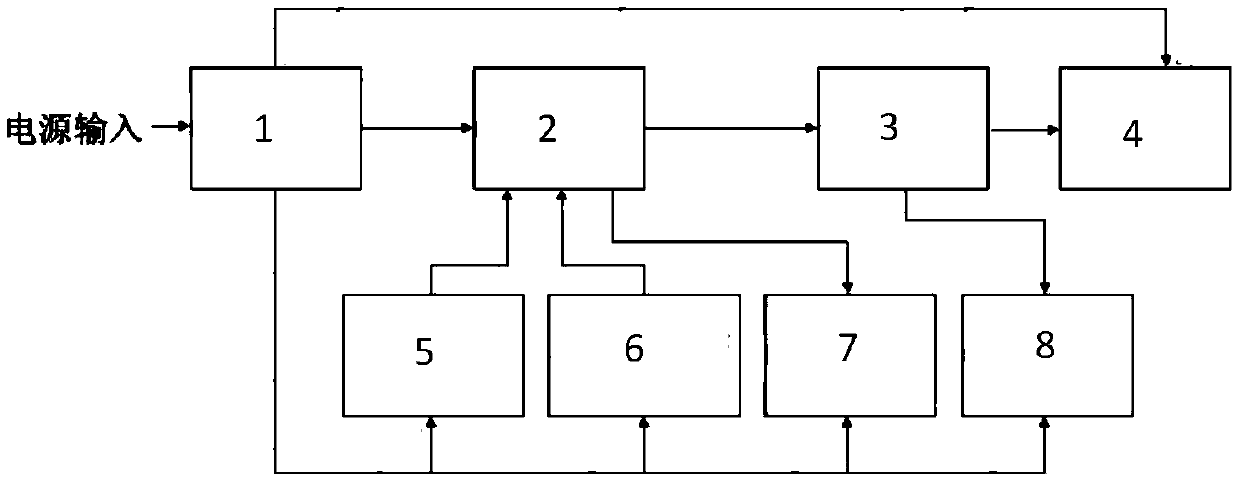

[0019] In this embodiment, an intelligent plant supplementary light includes a power supply module 1, a control unit 2, a drive unit 3, a transmission unit 4, an illumination sensor unit 5, a binocular camera unit 6, a WIFI module 7 and an LED supplementary light unit 8; The connection method of each component is: the power supply module 1 supplies power to the control unit 2, the drive unit 3, the transmission unit 4, the light sensor unit 5, the binocular camera unit 6, the WIFI module 7 and the LED supplementary light unit 8 respectively through cables, and the control The unit 2 is connected to the drive unit 3 through a cable, the light sensor unit 5 is connected to the control unit 2 through a wire to collect the brightness of the LED light, the binocular camera unit 6 is connected to the control unit 2 through a USB bus for image collection, and the WIFI module 7 is connected through a wire To the control unit 2, the LED supplementary light unit 8 is connected to the dri...

Embodiment 2

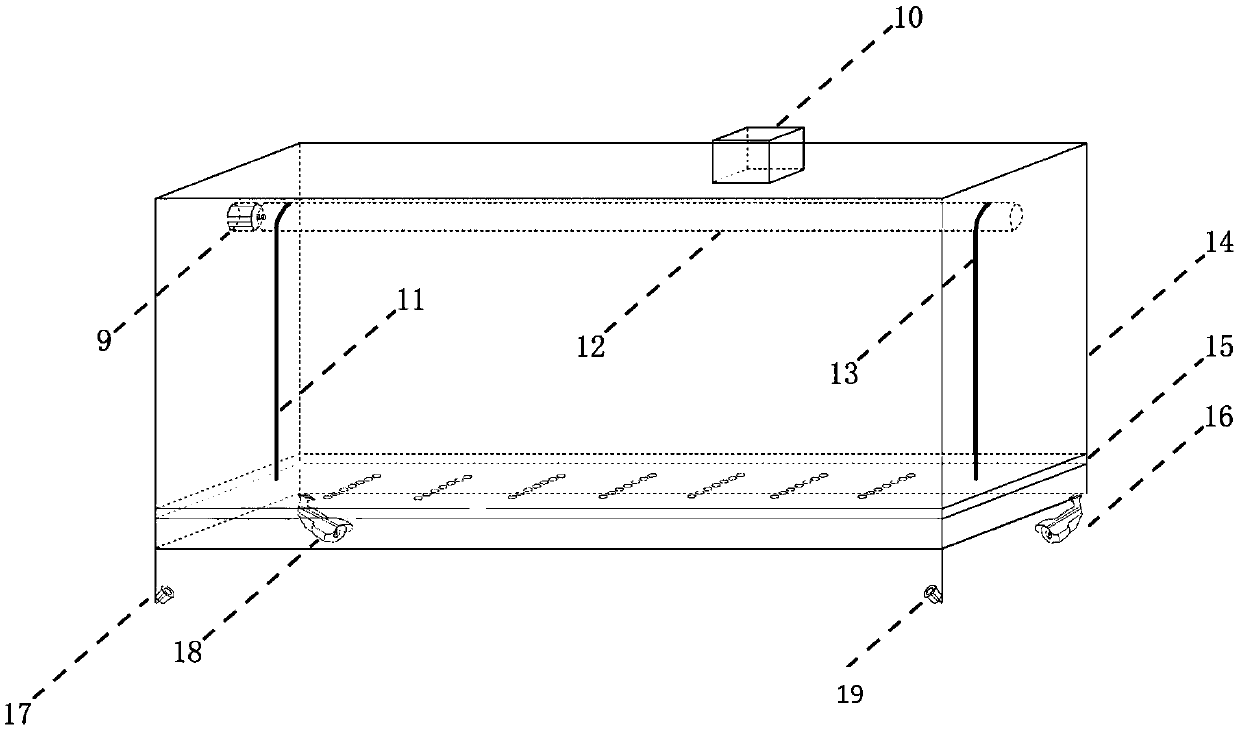

[0024] In the intelligent plant supplementary light of this embodiment, the circuit protection box 10 is installed on the top of the outer frame 14 of the LED supplementary light, and the power supply module 1, the control unit 2, the drive unit 3 and the WIFI module 7 are all installed in the circuit protection box. In 10, the motor 9 in the transmission unit 4 is connected to the rotating shaft 12, and the rotating shaft 12 is fixed on the upper part of the LED supplementary light outer frame 14 of the LED supplementary light unit 8, and the rotating shaft 12 is connected to the left transmission hinge 11 and the right transmission hinge 13, The left transmission hinge 11 and the right transmission hinge 13 are fixedly connected to the LED supplementary light board 15 in the LED supplementary light unit 8 to drive it up and down, and the left camera 18 and the right camera 16 in the binocular camera unit 6 are arranged outside the LED supplementary light respectively. At the ...

Embodiment 3

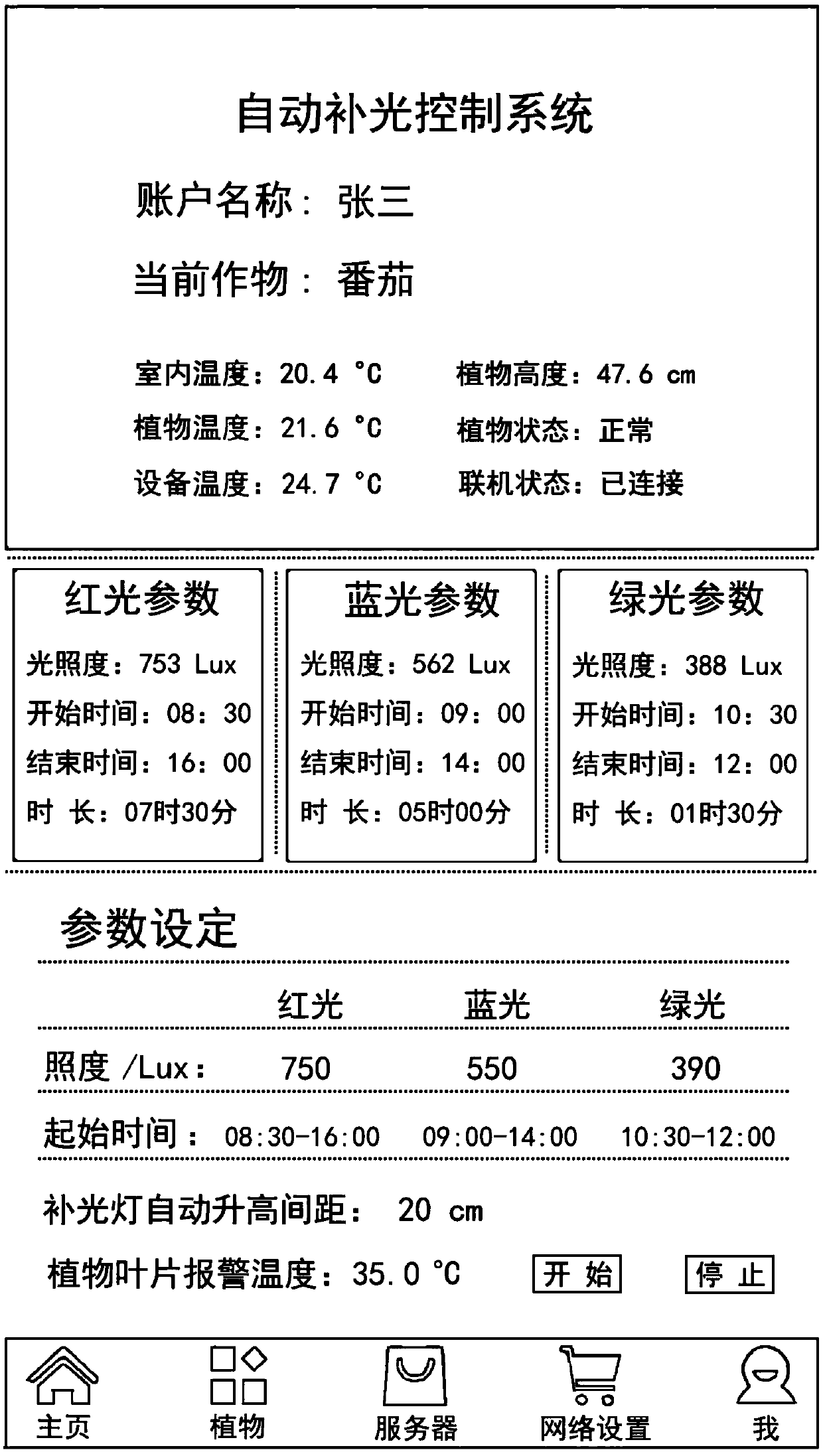

[0028] The control interface of a smart plant fill light in this embodiment is divided into the touch screen interface in the control unit 2 and the control interface of the mobile phone client. The two control interfaces have the same layout and function, and are divided into upper, middle and lower areas. For the user, plant and temperature information, the middle part is the real-time parameters of the three-color LED fill light, and the lower part is the fill light parameter setting area, the user will set the required red, blue and green three-color light intensity and fill light duration in this area, Finally, click the "Start" button to start the fill light program. When the user wants to stop the fill light operation in the middle, click the "Stop" button, the bottom five icons, the first "homepage" is the current control interface, the second "plant "Is the fill light parameter page for different plants. Select a plant to fill light. You don't need to set each fill lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com