Full-automatic shape following peeler

A peeling machine, fully automatic technology, applied to peeling utensils, household utensils, applications, etc., can solve the problems of time-consuming and labor-intensive, unable to achieve conformal effect, unable to remove peel, etc. Turn the handle, improve peeling efficiency, and avoid the effect of wasting pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

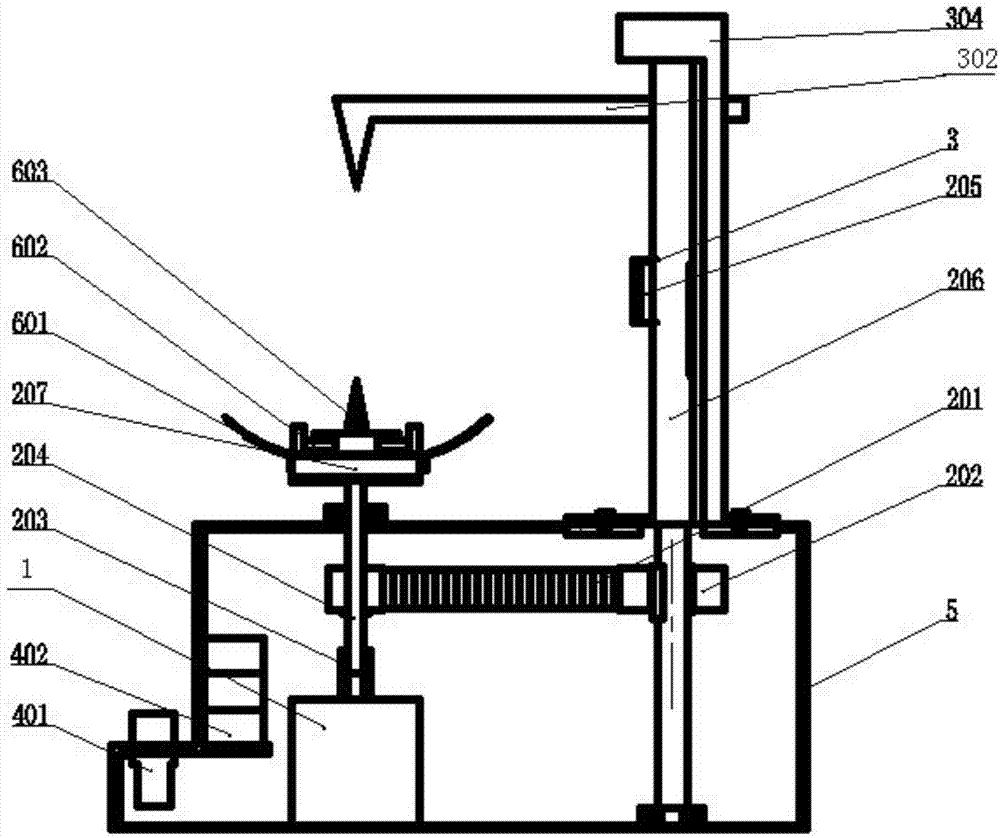

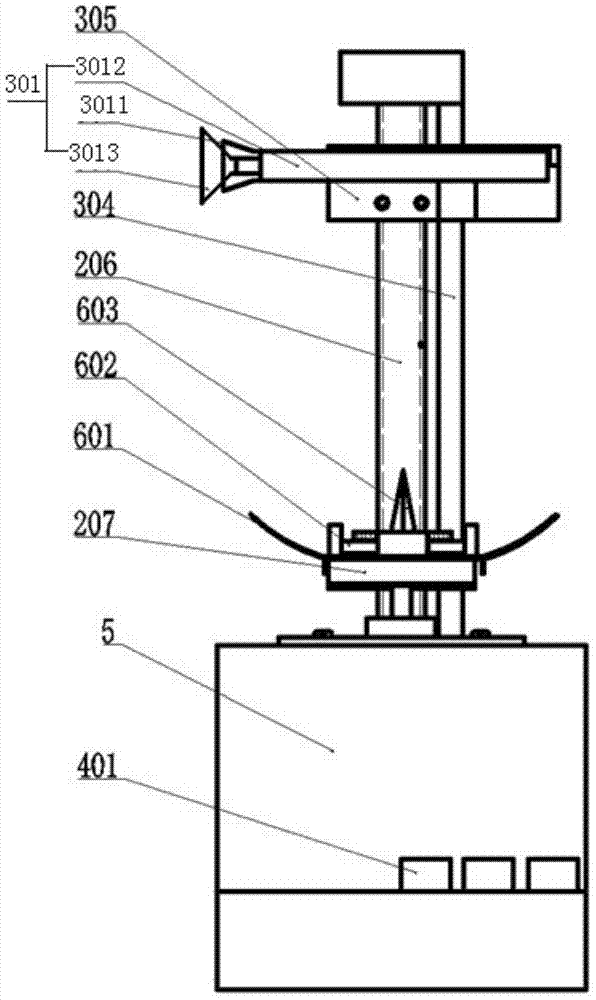

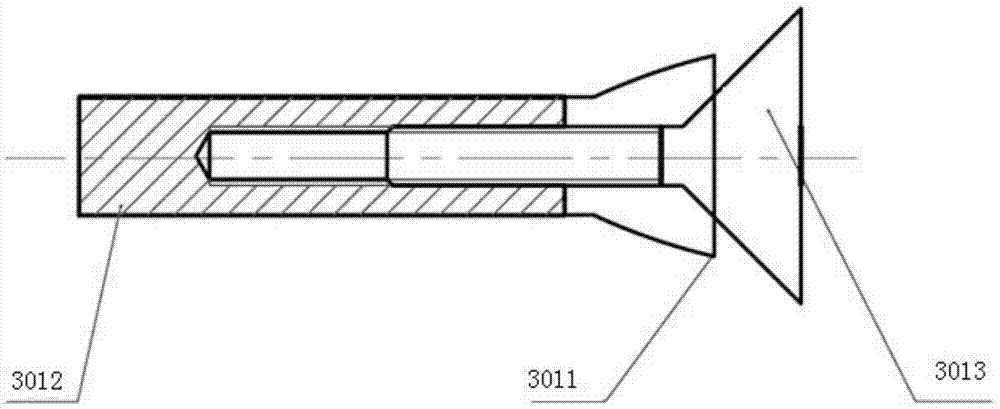

[0042] This embodiment adopts the above-mentioned connection method, wherein the fastening mechanism 6 includes a peel collection plate 601 and a support nail 603; the fruit peel collection plate 601 is connected to the internal tooth ratchet clutch 207 through bolts; the lower end of the support nail 603 is a boss, The upper end is tapered, and the lower end of the supporting nail is welded in the center of the peel collecting tray 601, and the number of supporting nails is 3. The cutter head 3011 includes a blade holder and a blade, and the blade includes a straight blade cd, a first arc blade de, a second arc blade ef and a third arc blade fc, and the shape specification of the blade holder is the same as that of the corresponding blade The shapes and specifications match, and the four blades are installed on the corresponding blade holders at the same time. Among them, the straight blade cd is mainly used for cutting the plane part of the upper and lower surfaces of the fr...

Embodiment 2

[0044] This embodiment adopts the above-mentioned connection method, wherein the fastening mechanism 6 includes a peel collection plate 601, a flap cutter 602 and a support nail 603; the fruit peel collection plate 601 is connected to the internal tooth ratchet clutch 207 by bolts; the support nail 603 The lower end is a boss, and the upper end is tapered, and the lower end of the supporting nail is welded in the center of the peel collecting tray 601, and the number of supporting nails is 3. The flap cutter 602 is provided with a central hole, and the flap cutter 602 is fixed on the peel collecting tray 601 by cooperating with the boss at the lower end of the support nail 603 through the center hole.

[0045] The cutter head 3011 includes a blade holder and a blade, and the blade includes a straight blade cd, a first arc blade de, a second arc blade ef and a third arc blade fc, and the shape specification of the blade holder is consistent with the shape specification of the co...

Embodiment 3

[0047]This embodiment adopts the above-mentioned connection method, wherein the fastening mechanism 6 includes a peel collection plate 601, a flap cutter 602 and a support nail 603; the fruit peel collection plate 601 is connected to the internal tooth ratchet clutch 207 by bolts; the support nail 603 The lower end is a boss, and the upper end is tapered, and the lower end of the supporting nail is welded in the center of the peel collecting tray 601, and the number of supporting nails is 3. The flap cutter 602 is provided with a central hole, and the flap cutter 602 is fixed on the peel collecting tray 601 by cooperating with the boss at the lower end of the support nail 603 through the center hole.

[0048] The cutter head 3011 includes a blade holder and a blade, and the blade includes a straight blade cd, a first arc blade de, a second arc blade ef and a third arc blade fc, and the shape specification of the blade holder is consistent with the shape specification of the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com