Disposal method and disposal device for greasy blockage of air conditioner system and air conditioner

An air-conditioning system and processing method technology, applied in the direction of heating and ventilation control system, heating and ventilation safety system, control input related to air characteristics, etc., can solve the problem of reducing the service life of compressors and systems, reducing operating power, and lack of oil in the system Fluorine deficiency and other problems can be achieved to improve the comfort of use, ensure the service life and improve the user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

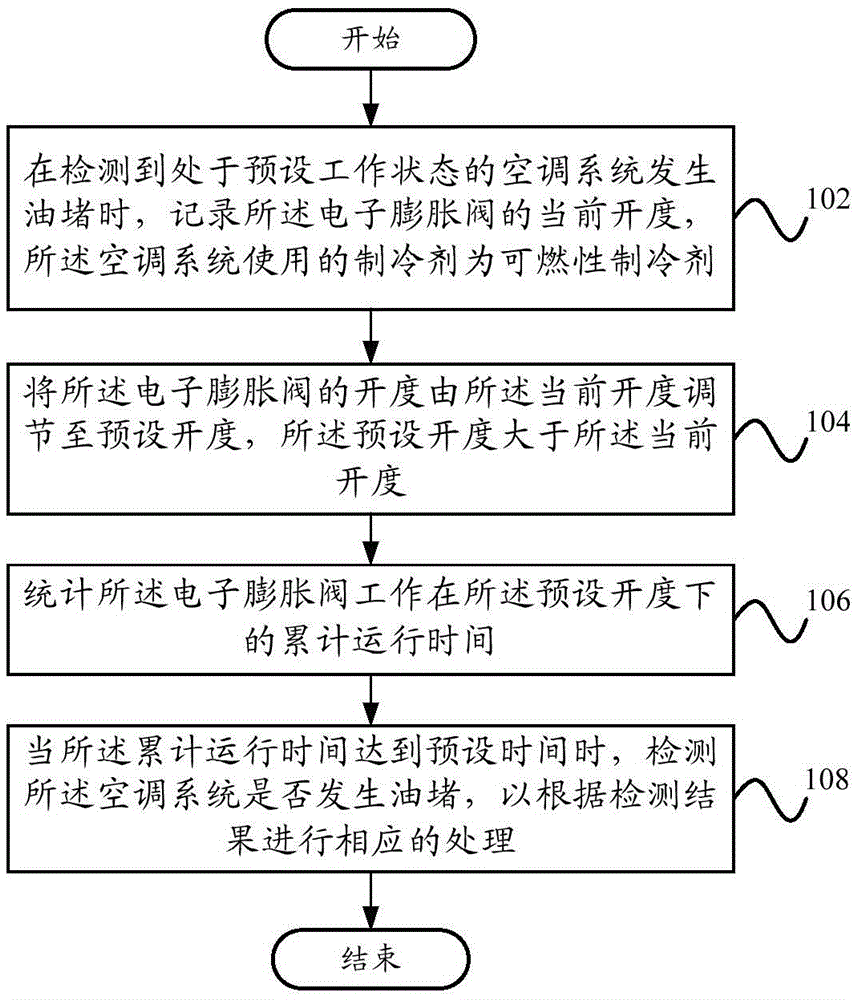

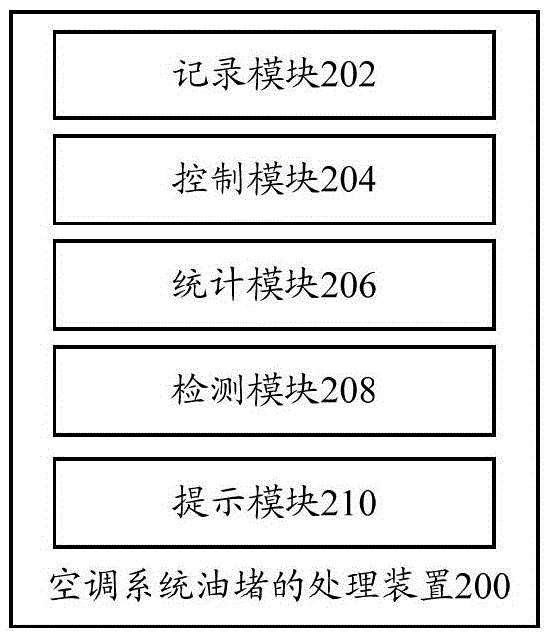

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: By using the system pressure value at the preset position of the compressor of the air conditioning system every first preset time, when it is determined that the system pressure value is less than or equal to the preset pressure value, it is determined that the air conditioning system has oil clogging. Specifically, the pressure value can be detected by a pressure detection module provided at the exhaust port or the return port of the compressor of the air conditioning system, wherein when the preset position is the return port of the compressor, the value of the preset pressure value The range is -0.1 MPa ~ 0.1 MPa, when the preset position is the exhaust port of the compressor, the value range of the preset pressure value is 0.5 MPa ~ 2 MPa.

Embodiment 2

[0058] Embodiment 2: By separately detecting the exhaust pressure value at the exhaust port of the compressor of the air conditioning system and the return air pressure value at the return port of the compressor every first preset time, and then determine the exhaust pressure value and When the difference of the return air pressure value (preferably the absolute value) is less than or equal to the preset pressure value (for example, 0.1 atmosphere, that is, 0.01 MPa), it is determined that the air conditioning system has been blocked by oil. Specifically, it can be set in the air conditioner The pressure detection module at the discharge port and return port of the compressor of the system detects the pressure value.

Embodiment 3

[0059] Embodiment 3: The exhaust temperature value at the exhaust port of the compressor of the air conditioning system and the return air temperature value at the return port of the compressor are detected every first preset time, and then the exhaust temperature value is determined When the difference between the return air temperature value is less than or equal to the preset temperature value (for example, 40°C), it is determined that the air conditioning system has been blocked by oil. Specifically, it can be set at the exhaust port and the return air port of the compressor of the air conditioning system The temperature detection module to detect the temperature value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com