Harmonic gear reducer starting torque and friction resistance torque testing system and method

A technology of gear reducer and starting torque, which is applied in the direction of machine gear/transmission mechanism test, force/torque/power measuring instrument, machine/structural component test, etc., to achieve a wide range of test applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

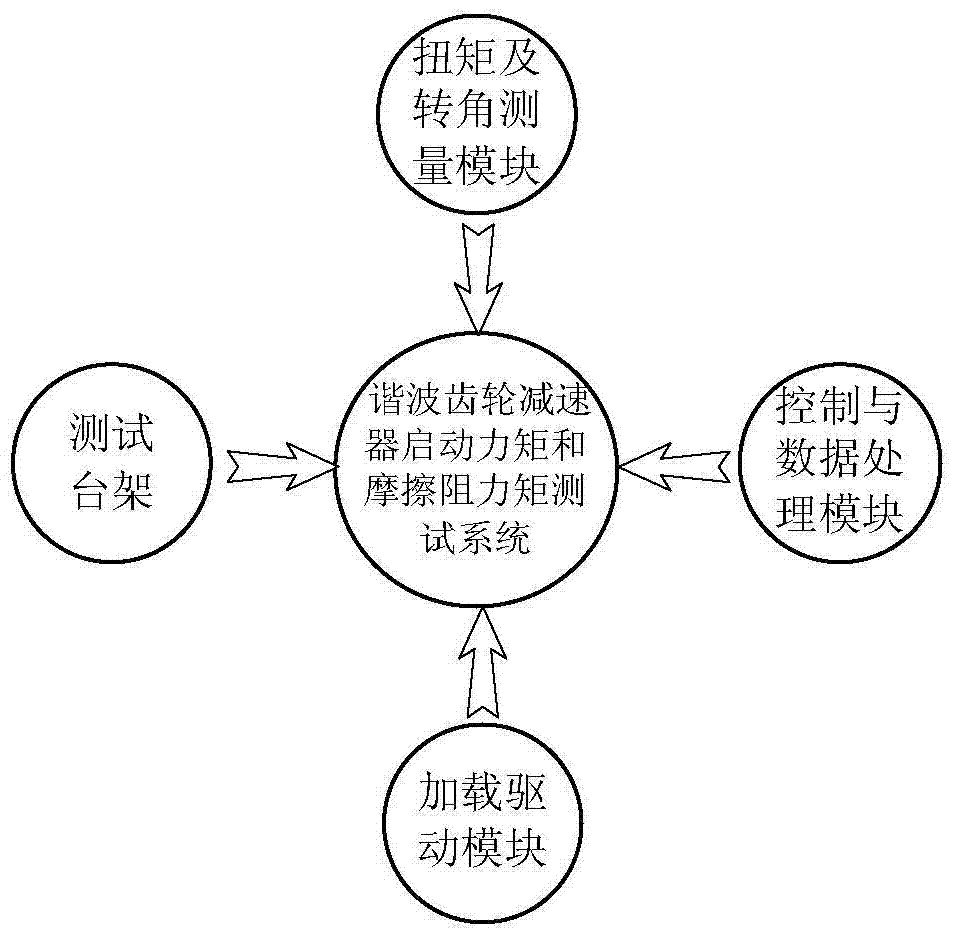

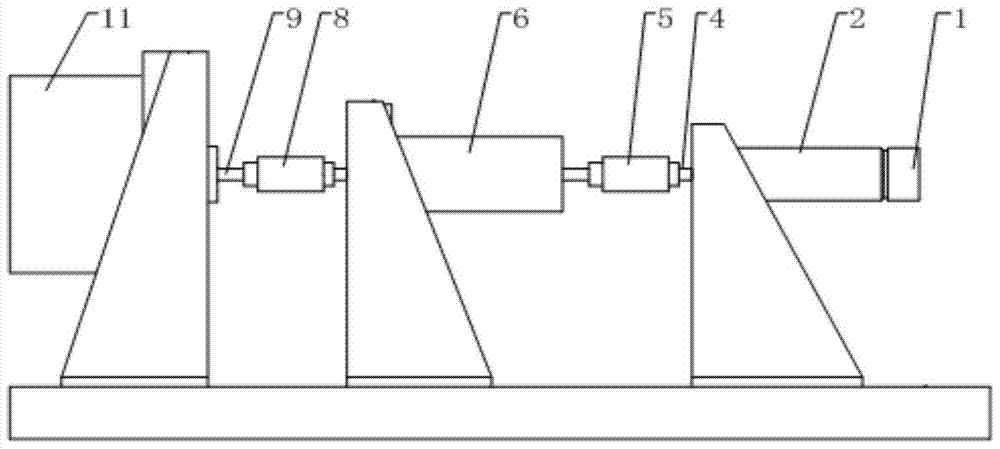

[0051] Such as figure 1 As shown, the present invention provides a starting torque and friction resistance torque testing system of a harmonic gear reducer, including: a loading drive module, a torque and rotation angle measurement module, a control and data processing module, and a test bench. Such as figure 2 As shown, the driving motor 2 is connected to the photoelectric encoder 1, the driving motor 2 is connected to the first coupling 5 through the connecting sleeve 4, the other end of the first coupling 5 is connected to the input end of the torque sensor 6, and the torque sensor 6 The test end is connected to the second coupling 8, and the measured harmonic reducer 11 is connected to the second coupling 8 through the adapter shaft 9. The measured harmonic reducer 11, the drive motor 2, and the torque sensor 6 are respectively fixed on the base on the three mounting brackets on the table.

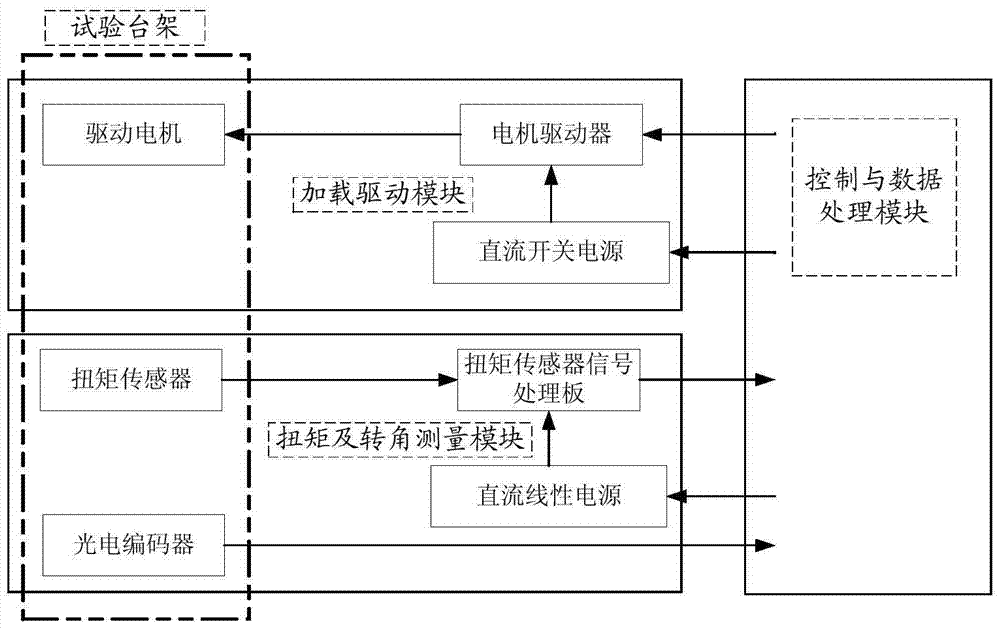

[0052] Such as image 3 , the loading drive module includes a motor driver, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com