Tap grounding apparatus and transformer bushing with same

A technology of transformer bushing and grounding device, applied in transformer/inductor parts, transformer/inductor coil/winding/connection, connection contact material, etc. Problems such as normal reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

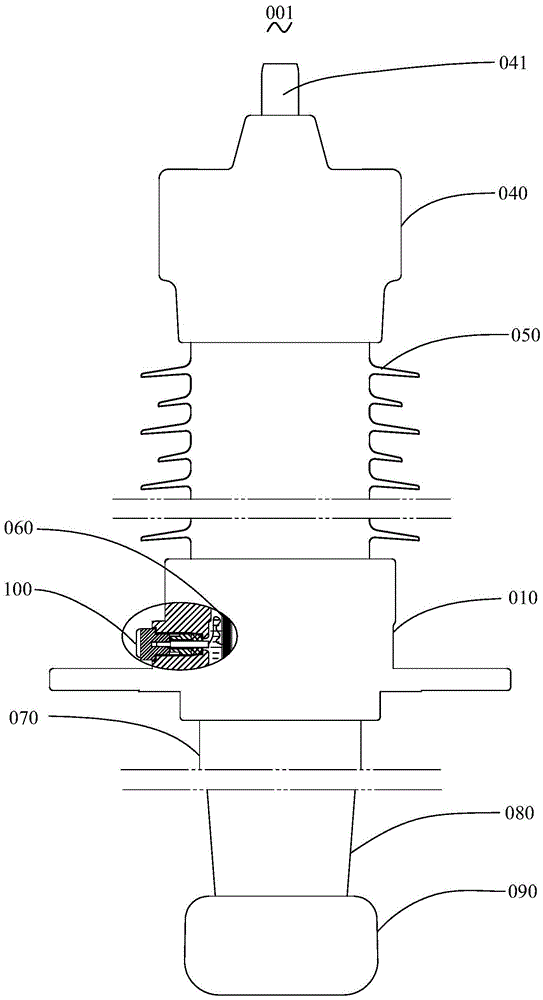

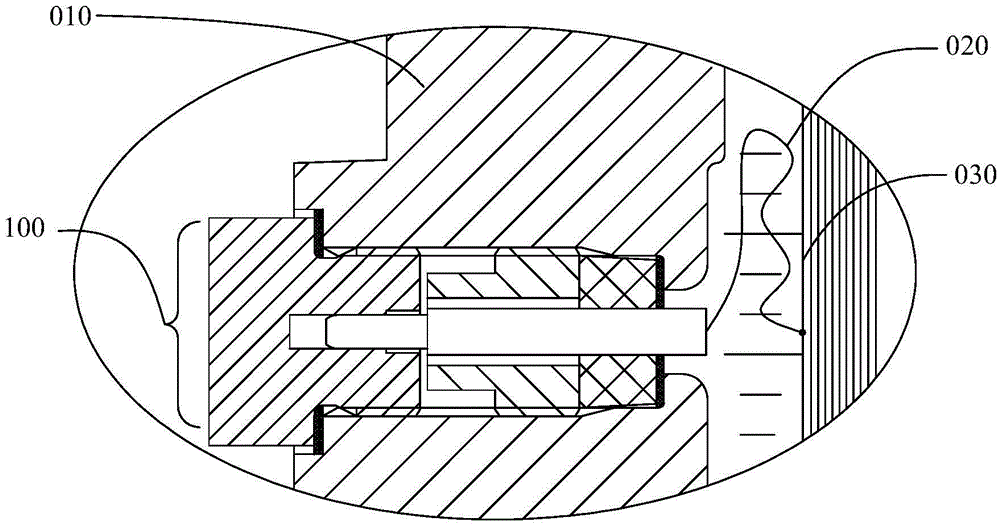

[0036] see figure 1 with figure 2 , the last screen grounding device 100 of the first embodiment of the present invention is installed on the transformer bushing 001 . Transformer bushing 001 includes base flange 010, end screen lead 020, head oil conservator 040, composite bushing 050, capacitor core 060, CT tube 070, oil-in-insulation tube 080, pressure equalizing ball 090 and fixed on the head External terminal 041 on oil conservator 040. The outermost layer of the capacitor core 060 is the last screen 030. Specifically, the last screen grounding device 100 is installed on the base flange 010 .

[0037] Since the transformer bushing 001 in this embodiment is equipped with the above-mentioned last screen grounding device 100, it can ensure effective and reliable grounding during operation and prevent damage accidents.

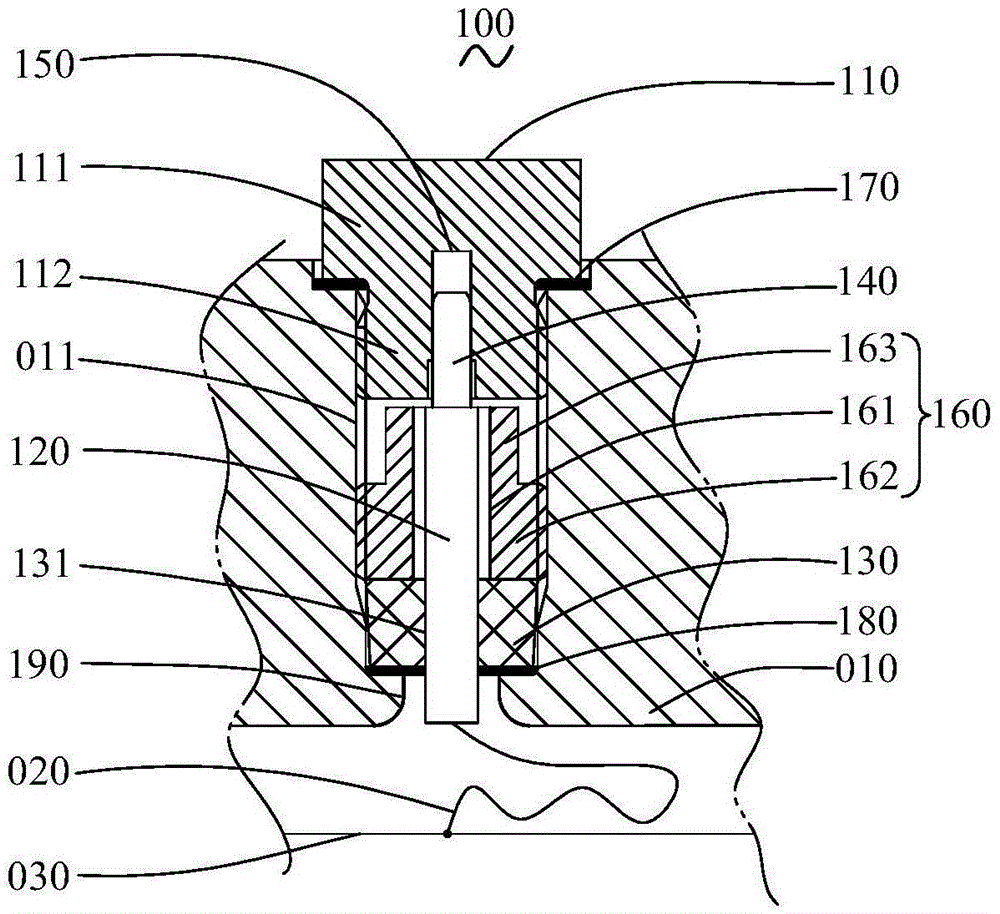

[0038] see image 3, The last screen grounding device 100 includes a ground base 110 , a ground post 120 , and an insulating base 130 . The base flang...

Embodiment 2

[0054] see Figure 8 , the second embodiment of the present invention is basically the same as the first embodiment. The difference from the first embodiment is that in the end screen grounding device 200 of the second embodiment, the boss 212 is provided with a pin terminal 240 and a grounding post 220 The upper end is provided with a jack 250 .

[0055] The working principle of the last screen grounding device 200 of the second embodiment is basically similar to that of the first embodiment, and will not be repeated here.

Embodiment 3

[0057] see Figure 9 The third embodiment of the present invention is basically the same as the first embodiment, and the difference from the first embodiment is that the end screen grounding device 300 of the third embodiment is not provided with a pressing member.

[0058] In this embodiment, the insulating base 330 is pressed and fixed in the first installation hole 012 through the ground base 310 . Specifically, the ground base 310 is covered on the first installation hole 012, the boss 312 extends into the first installation hole 012, the base 311 is provided with a number of through holes in the circumferential direction, and the end surface of the base flange 013 is provided with a number of corresponding holes. The grounding base 310 and the base flange 013 are fixedly connected by bolts (not shown). At this time, the end face of the boss 312 presses the insulating base 330, thereby pressing and fixing the insulating base 330 in the first mounting hole 012 middle.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com