Ground wire

A technology of grounding wires and connectors, applied in the direction of needle point/slotted plate contacts used to penetrate insulating wires/cable core wires, multi-core cable end parts, etc. Electricity and other problems, to achieve the effect of simple operation, strengthen the clamping effect, and ensure the safety of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

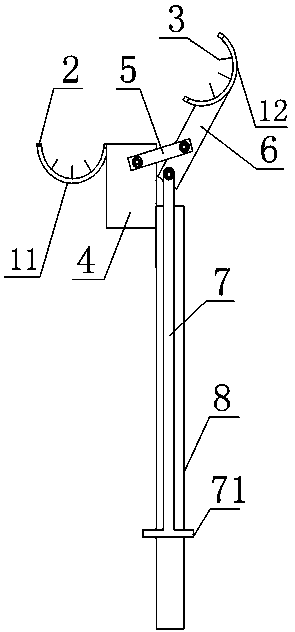

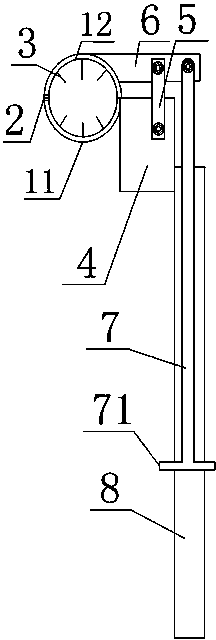

[0020] Such as figure 1 with figure 2 The shown grounding wire includes a fixed clamp block 11 and a movable clamp block 12 matched with the fixed clamp block 11, the fixed clamp block 11 and the movable clamp block 12 are provided with grooves, the fixed clamp block 11 A magnetic block 2 is arranged on the edge of the groove of the clamp block 11 and the movable clamp block 12, and a puncture needle 3 is arranged in the groove, and the fixed clamp block 11 is fixed on the fixed block 4, and the fixed block 4 is fixed with an operating rod 8, and the operating rod 8 is provided with a moving rod 7. The movable clamping block 12 is movably connected to the moving rod 7 through the connecting piece 6. The connecting piece 6 and the fixed block 4 A connecting rod 5 is movably connected between them, and a ground wire connecting device is arranged on the fixed block 4 or the fixed clamp block 11 .

[0021] In this embodiment, under the movement of the moving rod 7, the movable ...

Embodiment 2

[0024] Such as figure 1 with figure 2 The grounding wire shown in this embodiment is based on Embodiment 1. In order to facilitate the operation of the moving rod, the bottom of the moving rod 7 is fixed with an operating handle 71, and the operating rod 8 is provided with The chute, the operating handle 71 is located in the chute. The chute limits the moving position of the moving rod, so that the structure is stable during its operation.

Embodiment 3

[0026] Such as figure 1 with figure 2 Shown is a grounding wire. In this embodiment, on the basis of the above embodiments, at least two puncture needles 3 are respectively arranged in the grooves of the fixed clamping block 11 and the movable clamping block 12 .

[0027] The lengths of the puncture needles 3 are equal.

[0028] The puncture is aimed at the insulation layer of the cable. When the number of puncture needles is too small, that is, when there is only one on the fixed clamp block 11 and the movable clamp block 12, the cable is easy to move when the cable is punctured. When two puncture needles are used, the cables are placed on the two puncture needles, which will not move, so that the puncture is convenient for puncturing the cables. The lengths of the puncture needles 3 are equal, so that the depths of the puncture needles piercing into the cables are consistent, further ensuring the reliability of the grounding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com