A kind of driving thin film transistor and its preparation method

A thin-film transistor and semiconductor technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of reducing Ion, uneven carrier mobility, and pixel period pitch reduction, etc., to reduce the turn-on current Ion , to meet the high PPI pixel drive requirements, reduce the effect of operating current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

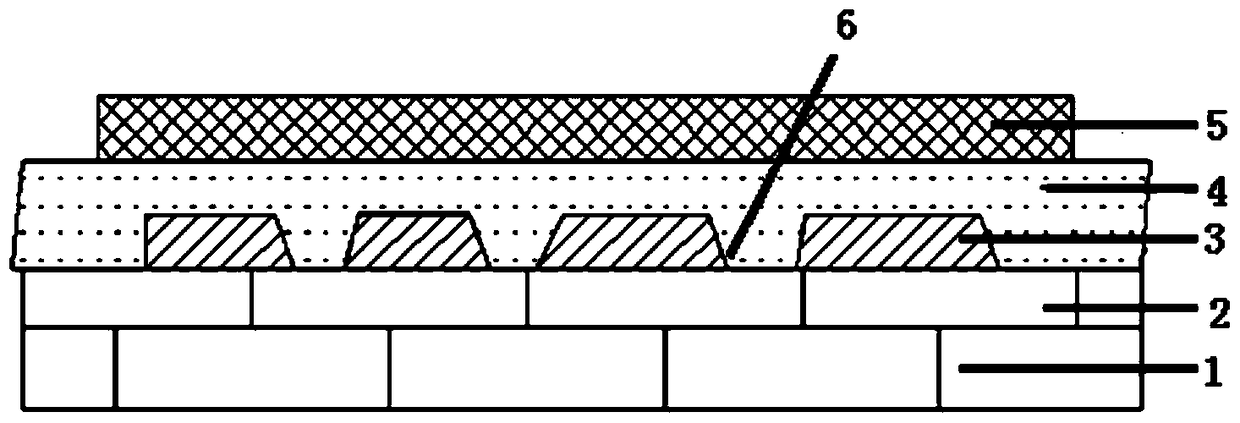

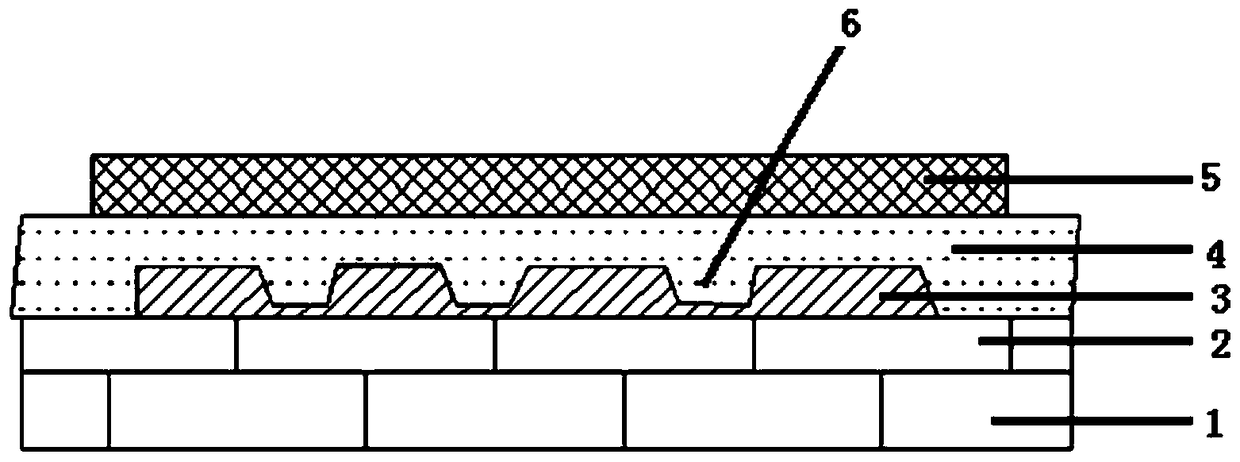

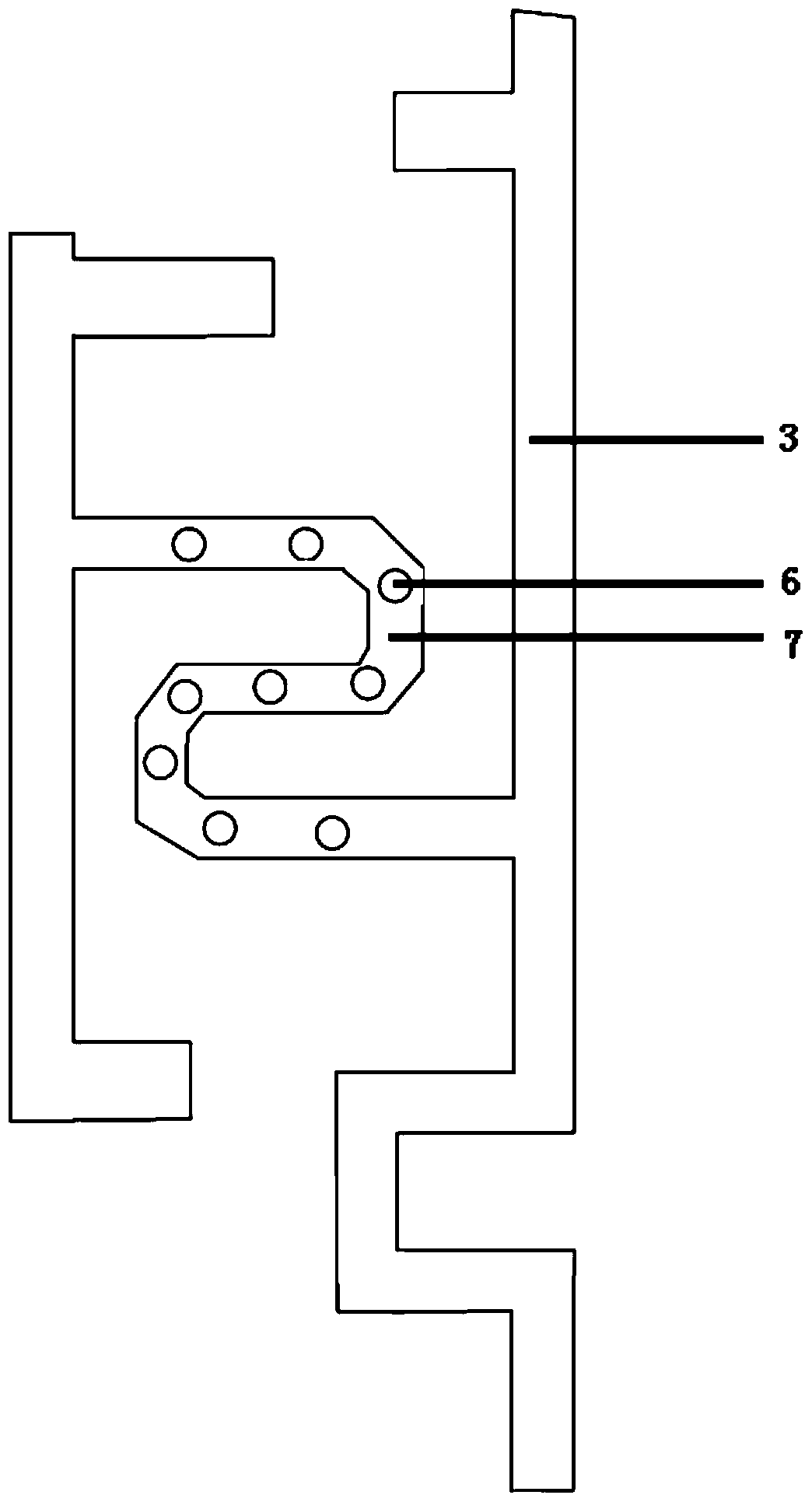

[0037] Such as figure 1 , figure 2 and image 3 As shown, several micropores 6 are arranged in the carrier transport channel 7, and the micropores 6 can hinder the transport of carriers. The centerline of the microhole 6 is perpendicular to the semiconductor layer 3 . Specifically, the centerline is defined as follows: image 3 The cross-sectional shape of the micropore 6 shown in is circular, and the straight line passing through the center of the circular section is the centerline of the micropore 6 . The height of the microhole 6 is less than or equal to the thickness of the semiconductor layer 3 . in figure 1 The height of the microhole 6 in the shown structure is equal to the thickness of the semiconductor layer 3, the figure 2 The height of the microholes 6 is smaller than the thickness of the semiconductor layer 3 . The cross-section of the microhole 6 can be a regular or irregular shape such as a circle, an ellipse, a triangle, and a pentagon. The micropores ...

Embodiment 2

[0039] Such as image 3 and Figure 4 As shown, the carrier transmission channel 7 of the driving thin film transistor of the present invention adopts an irregular sidewall structure, which is used to hinder the transmission of carriers. Specifically, the cross-section of the irregular side wall structure of the carrier transport channel 7 is zigzag or formed by sequentially connecting several arc-shaped structures, or a combination of regular and irregular shapes, the irregular The sidewall constitutes the carrier transport blocking structure. in Figure 4 The cross-section of the irregular side wall structure of the carrier transport channel 7 in the shown structure is formed by sequential connection of zigzag structures. Figure 5 The cross-section of the irregular side wall structure of the carrier transport channel 7 in the shown structure is formed by sequentially connecting several arc-shaped structures. In this embodiment, the sidewall of the carrier transmission c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com