The water tank wire drawing machine is based on the method of close arrangement of ultra-fine steel wires based on proximity switches

A water tank wire drawing machine and a proximity switch technology, which is applied in the field of water tank wire drawing machines based on the proximity switch close-packed extra-fine steel wire, can solve the problems of difficult encoder maintenance and high cost of servo motors, and achieve the effect of saving costs and simplifying post-maintenance work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments.

[0034] An embodiment of the present invention provides a water tank wire drawing machine based on a method for densely arranging extra-fine steel wires with a proximity switch, including the following steps:

[0035] S1: Install the first proximity switch for counting the number of rotations of the meter counting wheel per unit time, the second proximity switch for counting the number of rotations of the take-up wheel per unit time, and the Turn to the third proximity switch and the fourth proximity switch towards the base point to step S2.

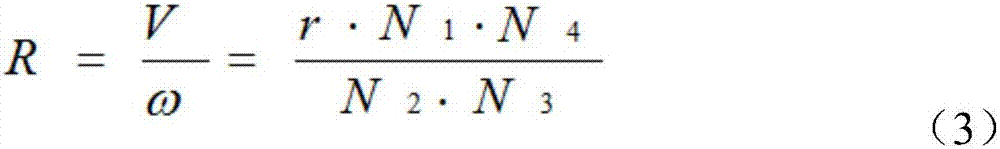

[0036] S2: The radius of the meter wheel is designed to be r, and the number of rotations of the meter wheel counted by the first proximity switch within time t is N 1 , the number of pulses per revolution of the meter wheel N 2 ; The number of turns of the take-up reel counted by the second proximity switch in the time t i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com