Metal separator

A metal separator and separator technology, applied in grain processing and other directions, can solve the problems of increasing labor intensity of workers, waste of powder materials, etc., and achieve the effect of saving labor costs and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

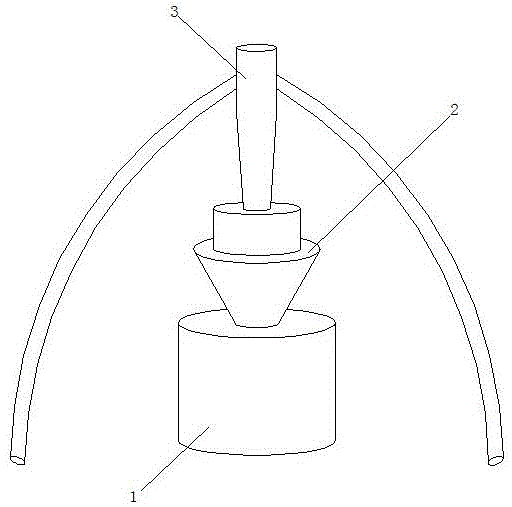

[0007] See figure 1 , This specific embodiment adopts the following technical solutions: it includes a separator 1, a hopper 2, a hopper 2 is arranged above the separator 1, and the hopper 2 is connected to the lower outlet of the suction bin 3, and the suction port of the suction bin 3 Connect with the outlet of the crusher. When working, the injection powder crushed by the pulverizer will be discharged through the outlet of the pulverizer, and then sucked in through the suction port of the hopper, and then sent to the hopper of the separator through the lower outlet of the hopper, and finally passed through the separator. The metal is separated, and the separator can be smashed and separated during the entire working process, which realizes automatic cycle work, saves personnel costs, reduces labor intensity of personnel, and avoids waste of powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com