A method for making a controllable and orderly unfolding solar sail based on shape memory polymer

A technology of memory polymer and production method, which is applied to the power supply system of aerospace vehicles, etc., can solve the problems of leaky solar sail structure, unstable deployment process, and poor deployment reliability, so as to ensure normal operation and simple deployment driving mechanism , the effect of not easy failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

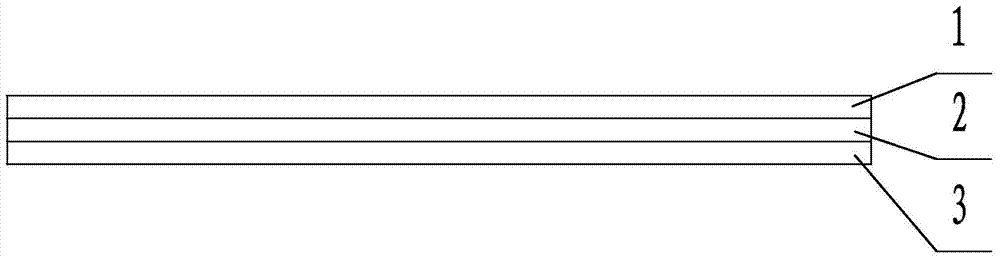

[0024] Specific implementation mode one: combine figure 1 , Figure 4 , Figure 5 To describe this embodiment,

[0025] A method for manufacturing a controllable and orderly unfolded solar sail based on a shape memory polymer, comprising the following steps:

[0026] Step 1, using one or more of epoxy thermoplastic shape memory polymers, epoxy thermosetting shape memory polymers, polyimide shape memory polymers, and cyanate shape memory polymers as the shape memory polymer material; add reinforcing material to the shape memory polymer material, then synthesize the shape memory polymer film with similar shape and size according to the shape and size of the flexible material reflective film with the shape memory polymer material after adding the reinforcing material, and Cover the electrothermal film on the shape memory polymer film;

[0027] Step 2. Make the flexible material reflective film and the electrothermal film respectively located on both sides of the shape memory ...

specific Embodiment approach 2

[0034] Specific implementation mode two: combination figure 2 , Figure 5 To describe this embodiment,

[0035] The shape-memory polymer film described in this embodiment is multi-segment, that is, the shape-memory polymer film contains multiple film units; the multiple film units of the shape-memory polymer film have different glass transition temperatures, and under the same heating conditions , the first to reach the glass transition temperature will be unfolded first, and the orderly deployment of the solar sail will be realized.

[0036]Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific implementation mode three: combination image 3 , Figure 5 To describe this embodiment,

[0038] The electrothermal film described in this embodiment includes a plurality of electrothermal film units, and the folded electric heating film units are sequentially energized and heated, so that the shape memory polymer films at different sections or at different units successively achieve vitrification. Change the temperature to realize the orderly deployment of the solar sail.

[0039] Other steps and parameters are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com