Automatic cone yarn bagging device

A bagging device and yarn bagging technology, applied in the field of bobbin automatic bagging devices, can solve the problems of manpower occupation and low bagging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings and specific implementations:

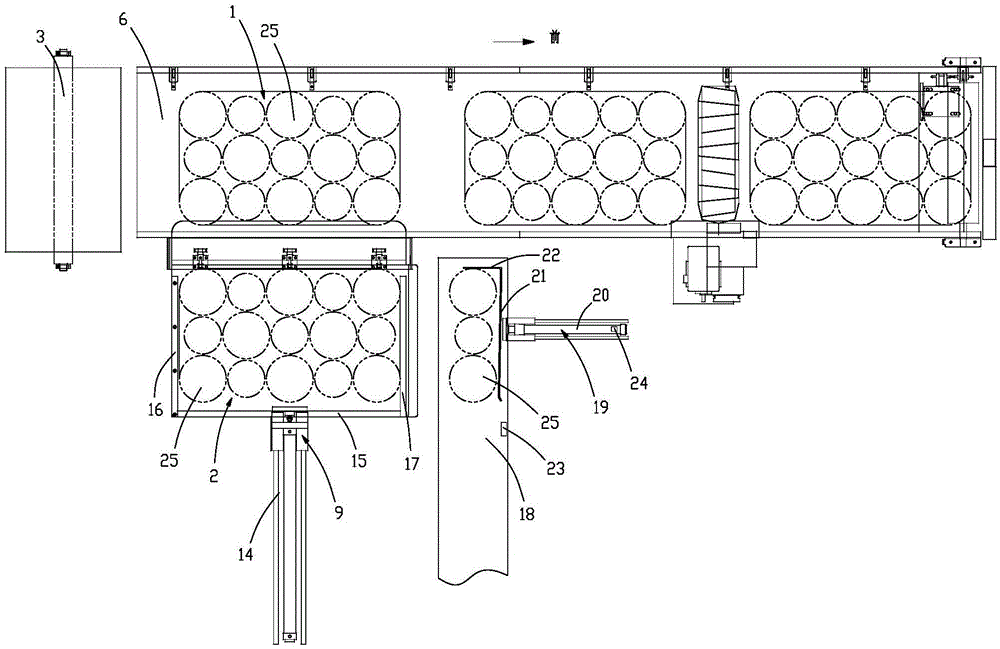

[0022] Combine figure 1 with figure 2 As shown, the automatic bagging device for cheese includes a cheese bagging area 1 and a cheese stacking area 2. Among them, the bagging operation of cheese 25 can be completed in the cheese bagging area 1, and the cheese stacking area 2 is used For the temporary storage and transfer of the package 25.

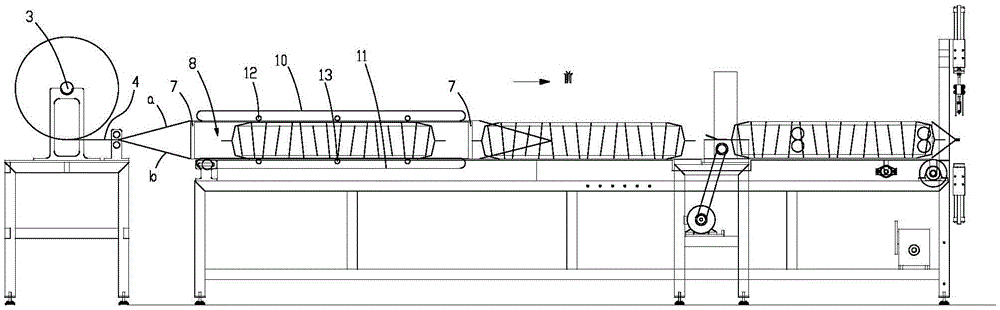

[0023] A reel 3 is arranged behind the package bagging area 1, and a double-layer unilateral opening belt 4 is wound on the reel 3. specific,

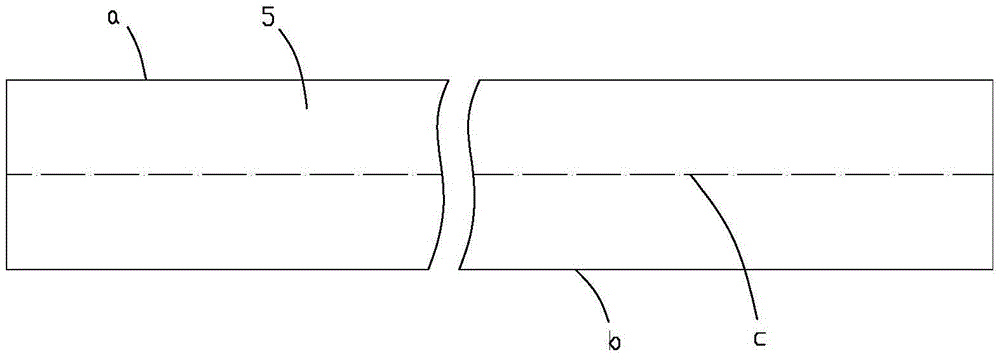

[0024] Such as image 3 As shown, the double-layer single-sided opening belt 4 is formed by folding two length edges a and b of a flat woven belt 5 in half. The distance between the length edge a and the center line c after being folded in half is equal to the distance between the length edge b and the center line c.

[0025] A main conveyor belt 6 is provided under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com