Sector-shaped liquid collection disc capable of containing multiple materials

A liquid contact tray, multi-material technology, applied in liquid bottling, liquid processing, bottle filling and other directions, can solve the problems of single type of material, small contact area of liquid tray, etc., to increase the liquid contact area, place Stable and avoid the effect of accidental pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

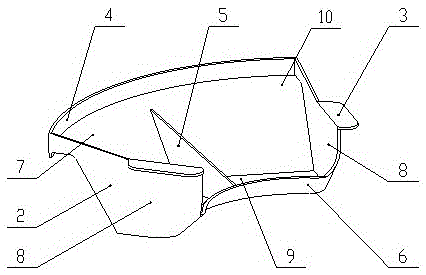

[0018] Such as figure 1 As shown, a fan-shaped liquid-receiving pan that can accommodate multiple materials adopts a fan-shaped structure, and its function is to coincide with the opening of the upper end surface of the suction hood of the bucket mouth to improve the sealing performance. The liquid receiving tray includes a tray body 2, an ear plate 3, a positioning plate 4 and a spacer plate 5; the tray body 2 adopts a cone ring form, including an inner ring plate 6, an outer ring plate 7, two side plates 8 and a bottom plate 9; The inner ring plate 6 and the outer ring plate 7 are arranged obliquely in the vertical direction, so that the cross-sectional area of the upper part of the disc body is larger than the cross-sectional area of the lower part, and the length and height of the outer ring plate are larger than the inner ring plate; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com