Wear-resistant S-shaped pipeline elbow and anti-abrasion treatment method of elbow

A pipe elbow, anti-wear technology, applied in the direction of elbows, pipes/pipe joints/fittings, siphons, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

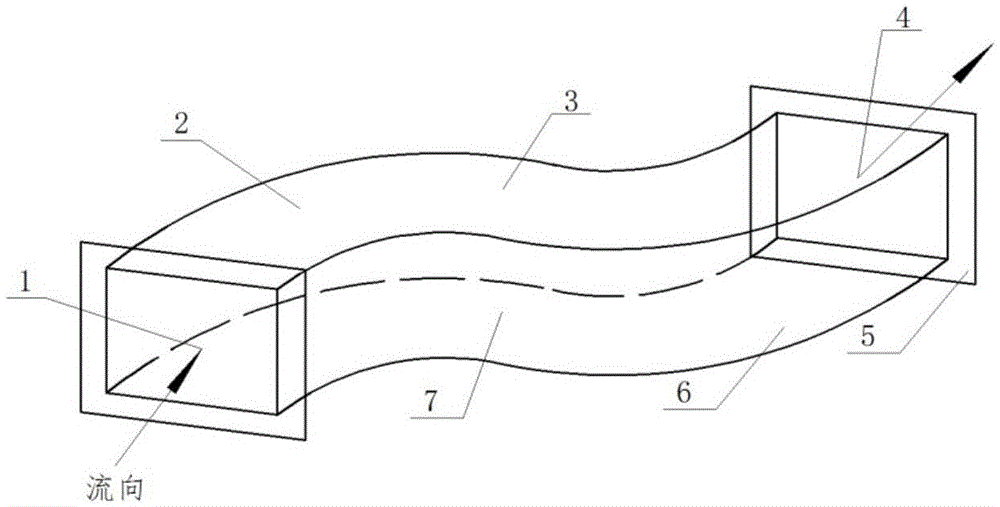

[0083] According to the above technical scheme, the cross-sections of the inlet and outlet of the S-shaped pipe elbow in this embodiment are both 320mm×250mm, and the thicknesses of the upper top plate, the lower bottom plate, the arc surface a and the arc surface b are all 0.5mm, and the S-shaped pipe elbow The elbow is formed by coupling two 90°pipe elbows. The inner radius of each 90°pipe elbow is 320mm and the outer radius is 640mm. Straight pipe section, a 2m long straight pipe section is connected to the outlet. According to the "Code for Design of Heating, Ventilation and Air Conditioning in Civil Buildings", the wind speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com