Propeller dynamic balance tester

A dynamic balance tester and balance test technology, applied in static/dynamic balance test, machine/structural component test, instrument, etc., can solve the problems of inability to test self-locking propeller dynamic balance performance, single test function, etc., to achieve The effect of testing is convenient and fast, expanding the scope of application, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

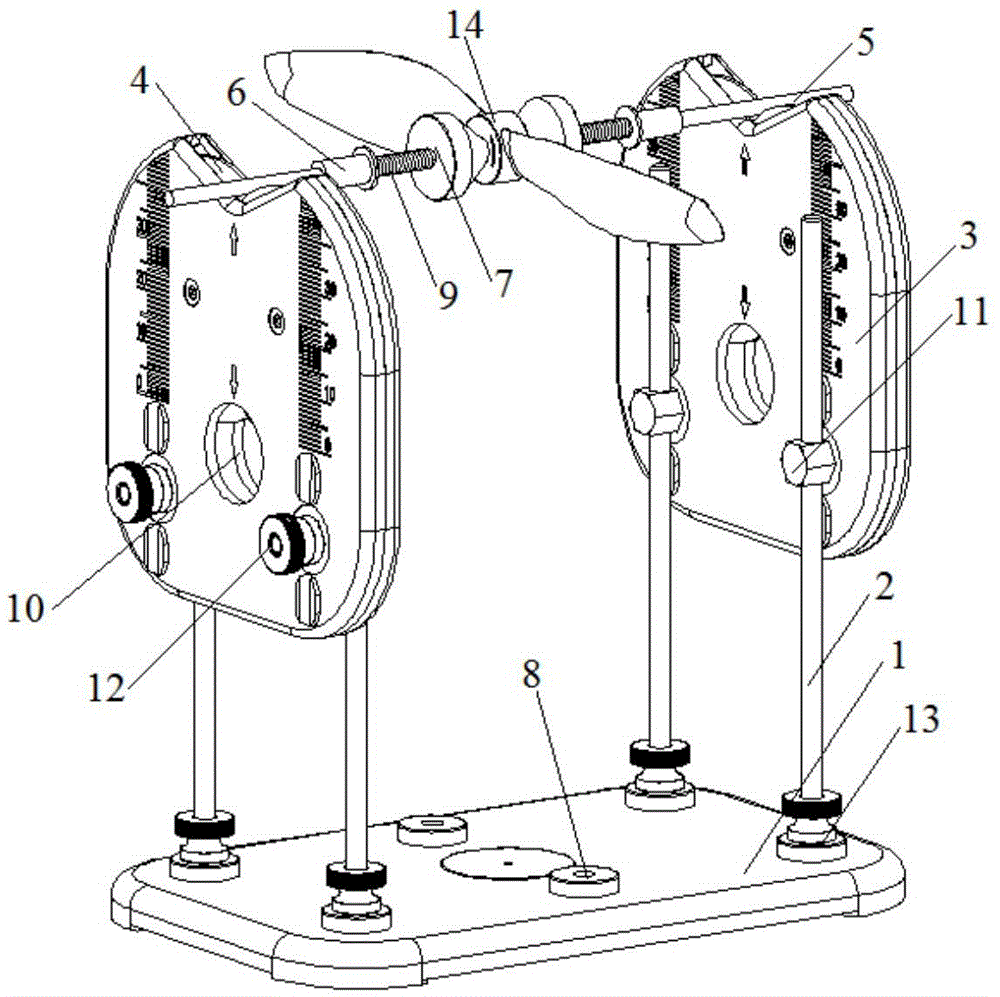

[0035] Such as figure 1 As shown, the present invention provides a propeller balance tester, which includes,

[0036] The base 1, preferably, the base is rectangular.

[0037] The support rod 2 is detachably arranged on the four corners of the base 1 by fixing screws 13, and the support rod 2 is installed on one end of the base 1 to be provided with threads, and the base 1 is provided with two rows of screw holes 8, Two rows of screw holes 8 are respectively arranged along the long sides of the rectangular base. In this embodiment, each row of screw holes 8 includes three screw holes, and the two rows of screw holes are arranged symmetrically along the center line of the base. Matched to fix the support rod 2, the two rows of screw holes 8 can be adapted to different types of propellers to be tested.

[0038] The fixed bracket 3 is a hollow structure with an upper end opening. In this embodiment, the opening is arranged directly above the fixed bracket 3, and the opening is...

Embodiment 2

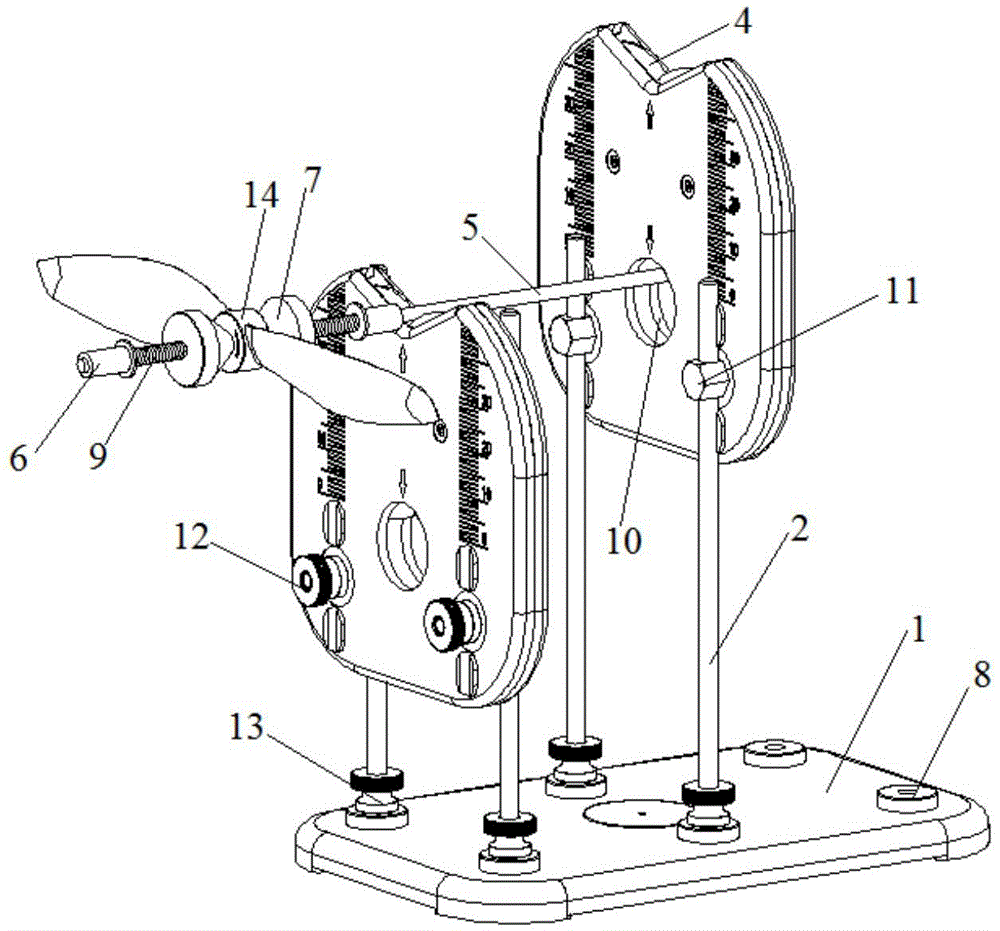

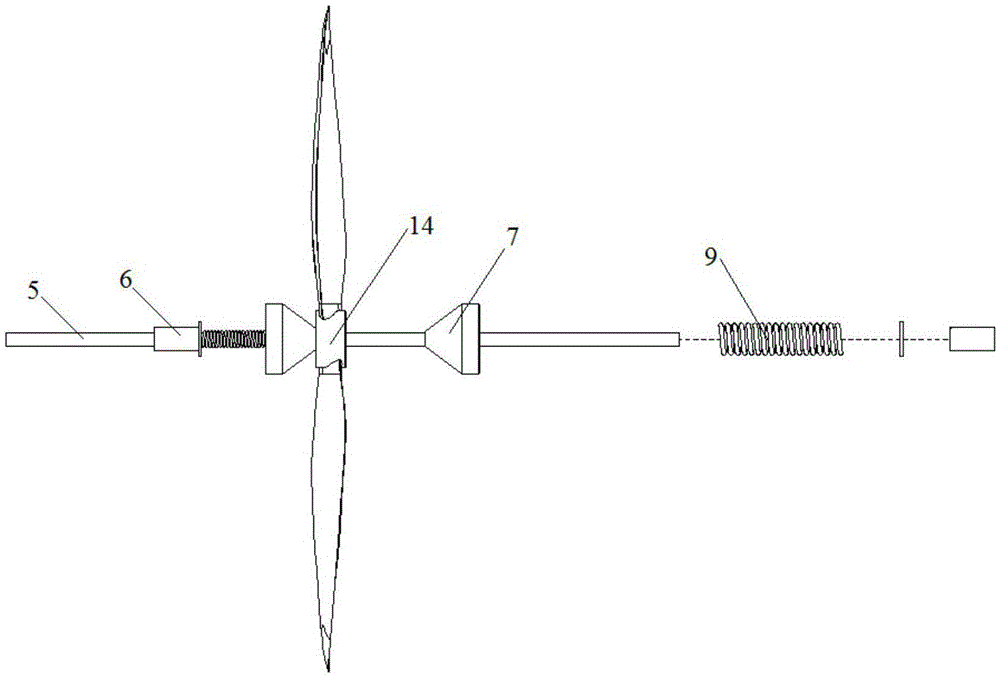

[0046] Such as Figure 4-5 As shown, the structure of the propeller tester described in this embodiment is basically the same as that of Embodiment 1, the difference is that the propeller tester in this embodiment can test the self-locking type with a closed nut structure at one end of the propeller hub 14. Propeller, therefore, the propeller tester of the present embodiment comprises:

[0047] base1;

[0048] The support rod 2 is detachably arranged on the base 1;

[0049] The fixed bracket 3 is a hollow structure with an upper end open, detachably connected to the support rod 2 and the position of the fixed bracket 3 on the support rod 2 is adjustable, and the fixed bracket 3 is two and opposite Setting, the two fixed brackets 3 are respectively provided with a through hole 10 along the part directly below the opening;

[0050] The balance test assembly 4 is arranged inside the hollow structure of each of the fixed brackets 3, and the working part of the balance test asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com