Digital integrated test technology of high-pressure gas source system

An integrated testing, high-pressure gas source technology, applied in the testing of mechanical components, the testing of machine/structural components, measuring devices, etc., can solve the problem of prolonging the application period of the bomb-borne high-pressure gas source system, affecting the development progress of the weapon system, and wasting manpower , material resources and other issues, to avoid complication and repetition, test safety and reliability, and reduce the number of tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

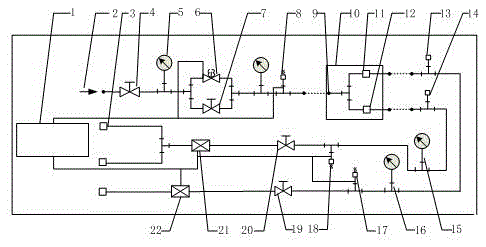

[0014] A preferred embodiment of a digital integrated testing technology for a high-pressure gas source system of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] figure 1 Show a specific embodiment of a high-pressure gas source system digital integration testing technology of the present invention: the high-pressure gas source system digital integration testing technology equipment includes interconnected control computer 1, external gas source 2, load 3, shut-off valve K14, pressure gauge P15, solenoid valve 6, cut-off valve K27, pressure transmitter 1 8, test port 9, tested high-pressure gas circuit system 10, pressure reducer 2 11, pressure reducer 1 12, relief valve 13, relief valve Two 14, pressure gauge P215, pressure gauge P316, pressure transmitter three 17, pressure transmitter two 18, stop valve K419, stop valve K320, flow meter one 21, flow meter two 22, digital integration of the high pressure gas sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com