Contact assembly for electromechanical switching device, and electromechanical switching device

A technology of contact device and electromechanical switch, which is applied in the direction of electric switch, electromagnetic relay, detailed information of electromagnetic relay, etc., can solve the problem of increasing assembly cost and achieve the effect of reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

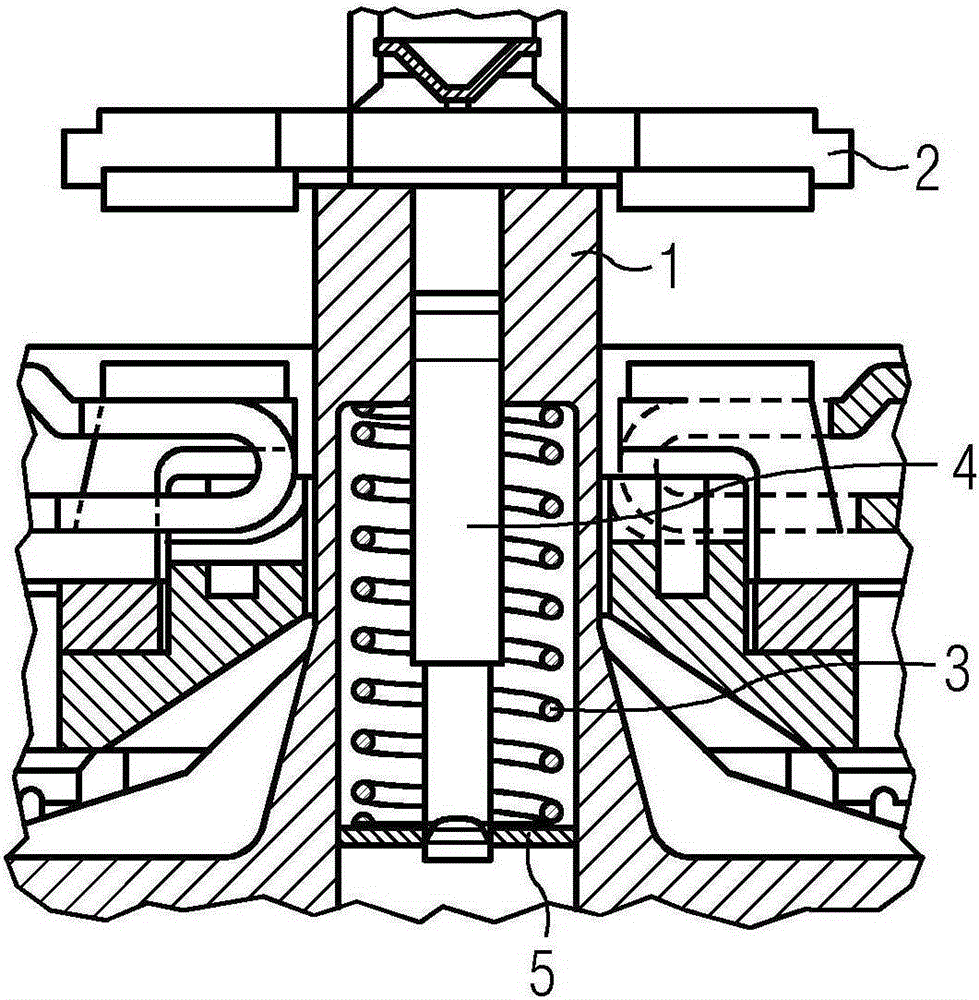

[0029] FIG. 1 shows a contact device known from the prior art with a contact carrier 1 which guides a movable switching part 2 , wherein the movable switching part 2 is loaded on one side by a contact spring 3 . On the opposite side, that is to say on the side of the movable switching part 2 , the spring bow 4 is introduced into the contact carrier 1 . In order to support the contact spring 3 , a steel plate 5 is fitted under the contact spring 3 through a rotational movement.

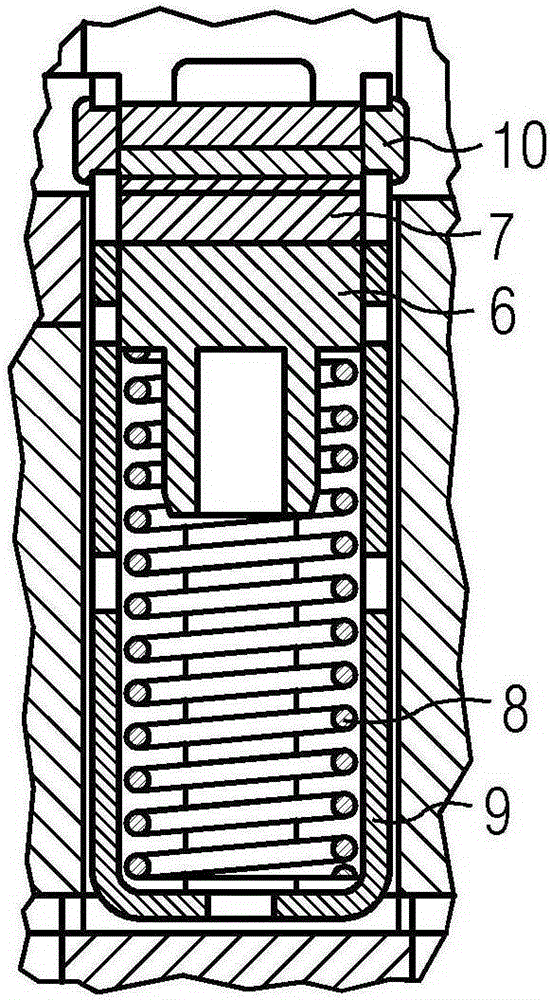

[0030] A further contact arrangement known from the prior art is shown in FIG. 2 . FIG. 2 shows a contact device with a contact carrier 6 which guides a movable switching part 7 , wherein the movable switching part 7 is supported on a contact spring 8 which is inserted from below into the contact carrier 6. Likewise, the spring bow 9 is pushed into the contact carrier 6 from below. The movable switching element 7 is located from above between the two legs of the spring bow 9 . By pressing one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com