Integrated cast copper rotor

An all-in-one, cast-copper technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of desoldering, low reliability of copper bar rotor, copper bar movement, etc., to achieve reliable The effect of improving performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

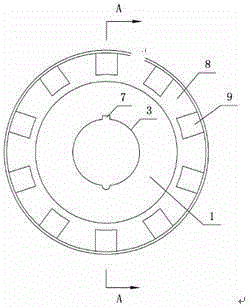

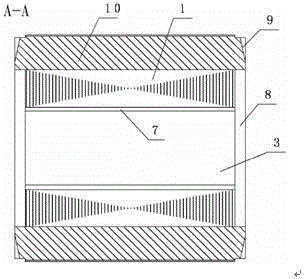

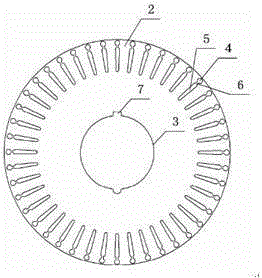

[0016] Examples, see attached figure 1 , a one-piece cast copper rotor, including rotor core 1, silicon steel sheet 2, mounting hole 3, round hole 4, waist-shaped hole 5, gap 6, radial fixing groove 7, pressure plate 8, rectangular groove 9 and guide bar 10. It is characterized in that: the rotor core 1 is formed by laminating a certain number of silicon steel sheets 2 of the same size and shape, the center of the silicon steel sheet 2 is provided with a mounting hole 3, and a certain number of silicon steel sheets are evenly distributed around the silicon steel sheet 2. The guide bar holes in each silicon steel sheet 2 are stacked and connected to form guide bar grooves in the rotor core 1, guide bars 10 are die-cast in the guide bar grooves, and the two ends of the rotor core 1 are provided with pressure plates 8 , the pressing plate 8 is connected together with the guide bar 10 by die-casting, the shape of the silicon steel sheet 2 is circular, and the guide bar hole on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com