Restructured bamboo or wood automatic production system

A production system and technology for reconstituting bamboo, applied in the direction of wood compression, wood processing appliances, household components, etc., can solve the problems of difficult product quality, low degree of automation, high labor intensity, etc., and achieve technological progress in the industry, stable product quality, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below with embodiment 。

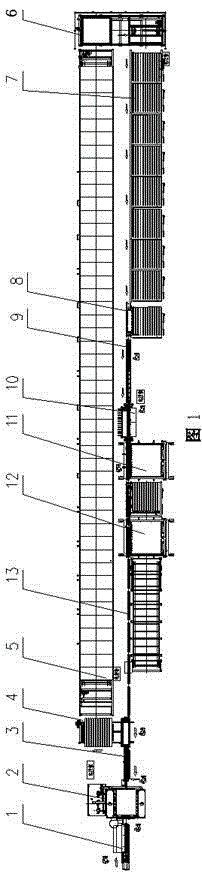

[0013] Such as figure 1 As shown, a recombinant bamboo automatic production system includes a feeder 1, the discharge end of the feeder 1 is connected to a PLC controllable rapid molding machine 2; the discharge end of the PLC controllable rapid molding machine 2 is connected to an automatic mold release and transfer Machine 3; automatic mold release and transfer machine 3, the discharge end is connected to automatic jacking and transferring machine 4; the top of automatic jacking and transferring machine 4 is connected to the head end of PLC controllable automatic continuous curing conveyor line 5; PLC controllable automatic continuous curing conveyor The end of the line 5 is connected to the trolley type automatic transfer unit 6; the trolley type automatic transfer unit 6 is connected to the cooling transfer unit 7, the cooling transfer unit 7 is connected to the automatic mold splitter 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com