A universal transmission mechanism and an omnidirectional treadmill driven by the universal transmission mechanism

A universal transmission and treadmill technology, applied in the field of machinery, can solve problems such as inconvenience in use, troublesome maintenance, and reduce the scope of application of the treadmill, and achieve the effects of a simple directional linkage mechanism, a simple basic structure, and an increase in the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

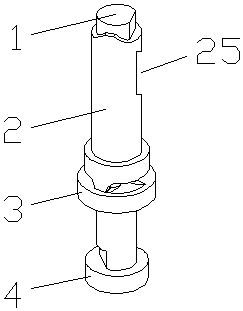

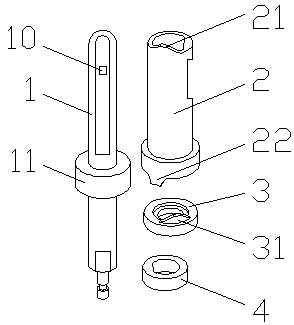

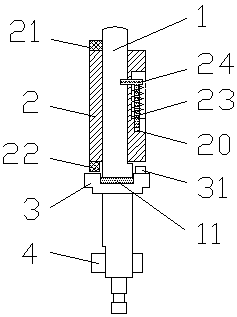

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] As shown in the figure, a universal transmission mechanism includes a support shaft 1, wherein a power receiving mechanism for receiving external power is provided outside the support shaft 1, and a power receiving mechanism for controlling the power transmission direction is provided outside the support shaft 1. The direction mechanism, the power receiving mechanism is connected with the direction mechanism, by controlling the rotation of the direction mechanism, the contact position between the direction mechanism and the power receiving mechanism is changed, and finally the speed direction is changed.

[0023] The power receiving mechanism includes a power input mechanism and a power output mechanism, the power input mechanism and the power output mechanism are both linked with the support shaft 1, the power output mechanism is connected with the direction m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com