Wheel type tobacco plant spacing positioner

A roulette-type, locator technology, applied in planting methods, applications, agriculture, etc., can solve the problems of inconsistent supply of nutrients, moisture, sunlight, easy changes in the tightness of plastic ropes, and inability to ensure the consistency of plant spacing. The effect of low production cost, high efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

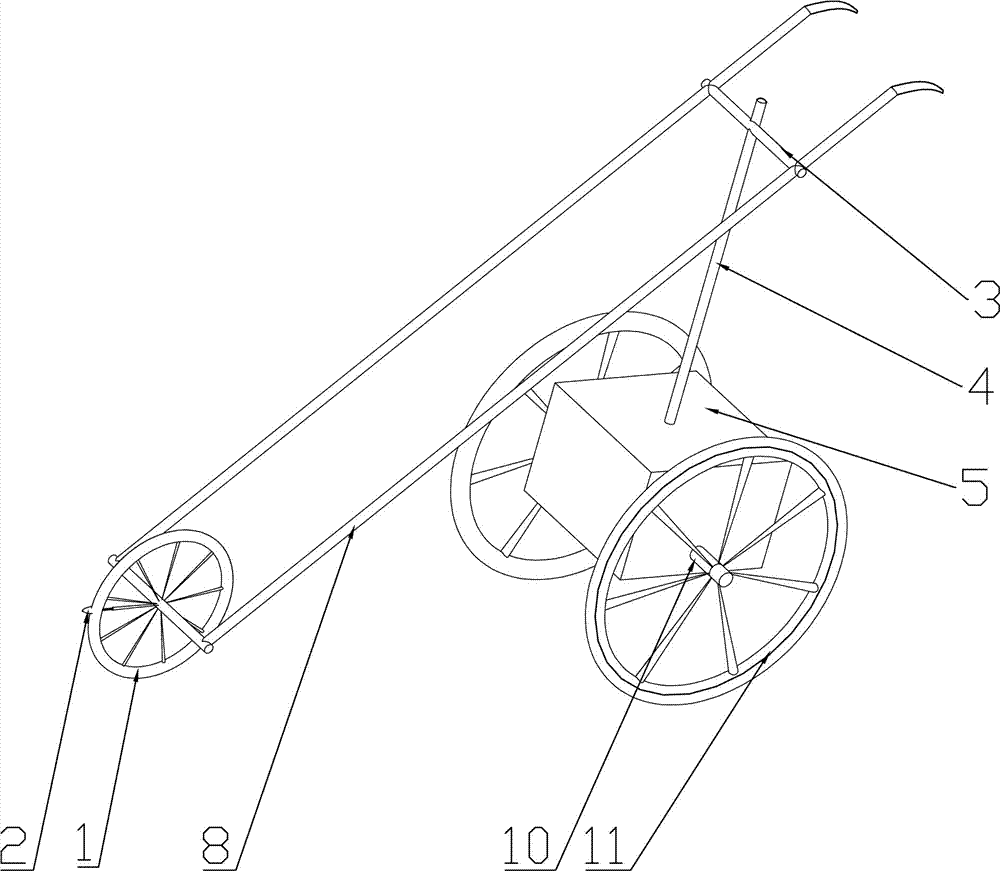

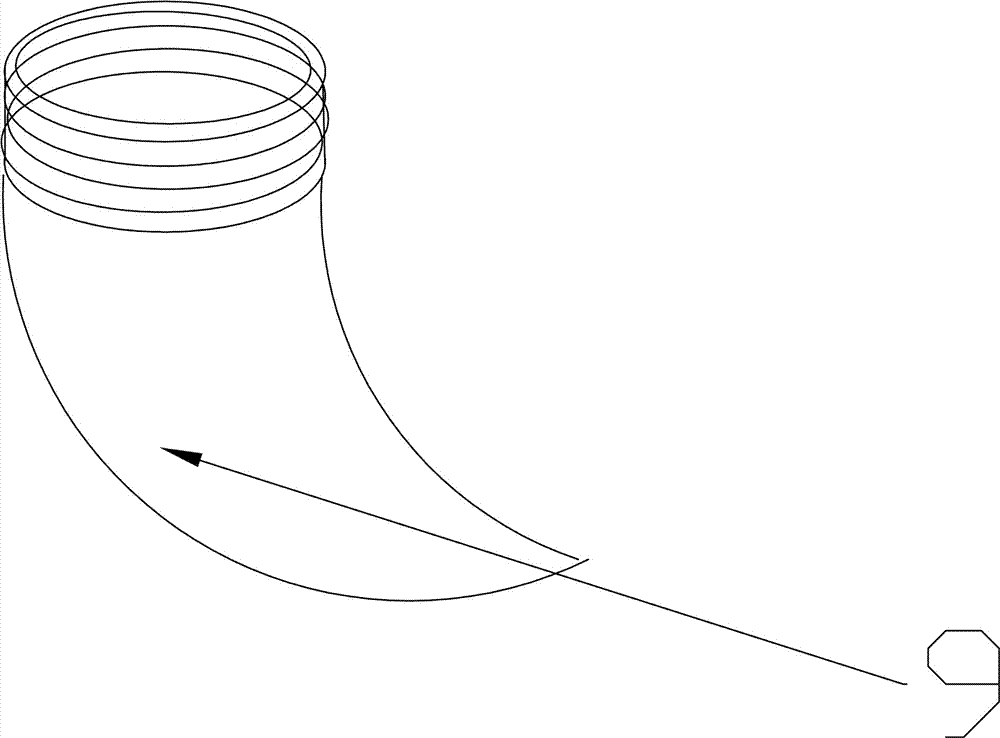

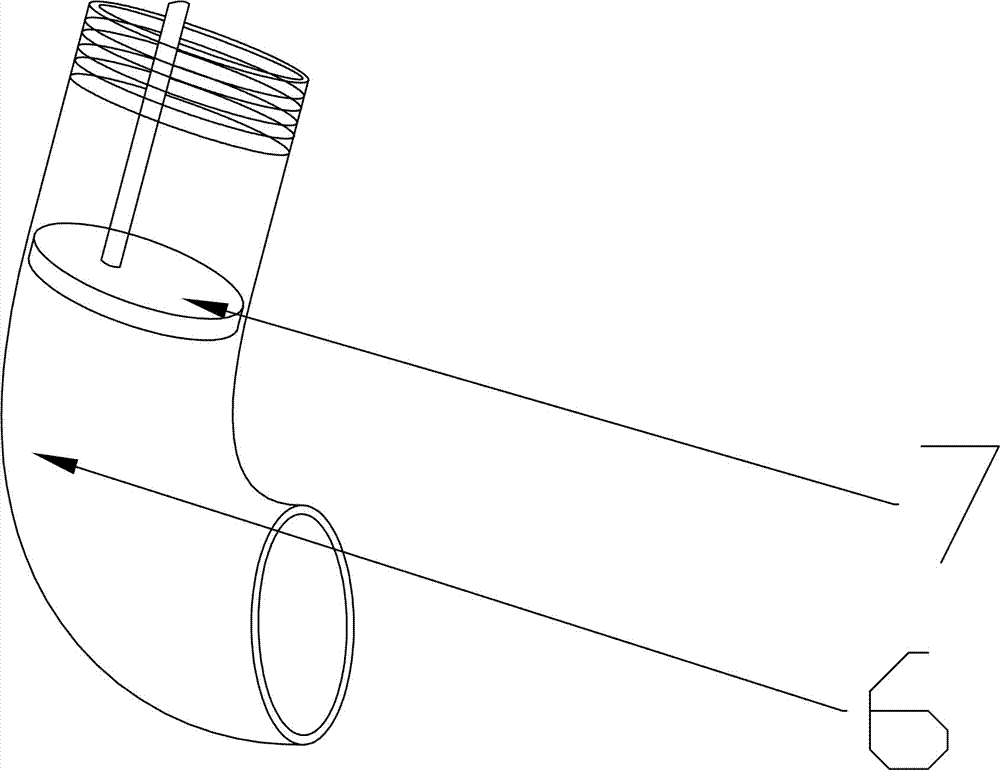

[0022] Such as Figure 1~3 Shown, a kind of tobacco wheel-type plant distance locator comprises bracket 8, and front wheel 1 is installed on the front end of bracket 8, and front wheel 1 is provided with threaded hole, and a punching mechanism 2 is threadedly connected with front wheel 1 by threaded hole, The punching mechanism 2 is a cone 9 with an external thread on the upper end, and the cone 9 is arc-shaped. The direction of curvature of the rear cone 9 is installed to be consistent with the steering of the front wheel 1, so that the punching is quick and effective. The circumference of the front wheel 1 is 50-55cm or 55-60cm. According to the current tobacco leaf transplanting technical regulations, the plant spacing of Burley tobacco is 50-55cm, and the flue-cured tobacco is 55-60cm. Quantitative design, when the front wheel 1 rolls a circle, the track of motion is exactly equal to the distance between plants. When positioning, first stretch a straight line on the ridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com