Self-reset leak-proof air ejection system

An automatic reset, leak-proof technology, applied in jet pumps, machines/engines, non-displacement pumps, etc., can solve the problems of limited application range, short service life, slow suction speed, etc., and achieve long service life and basic structure. Simple, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

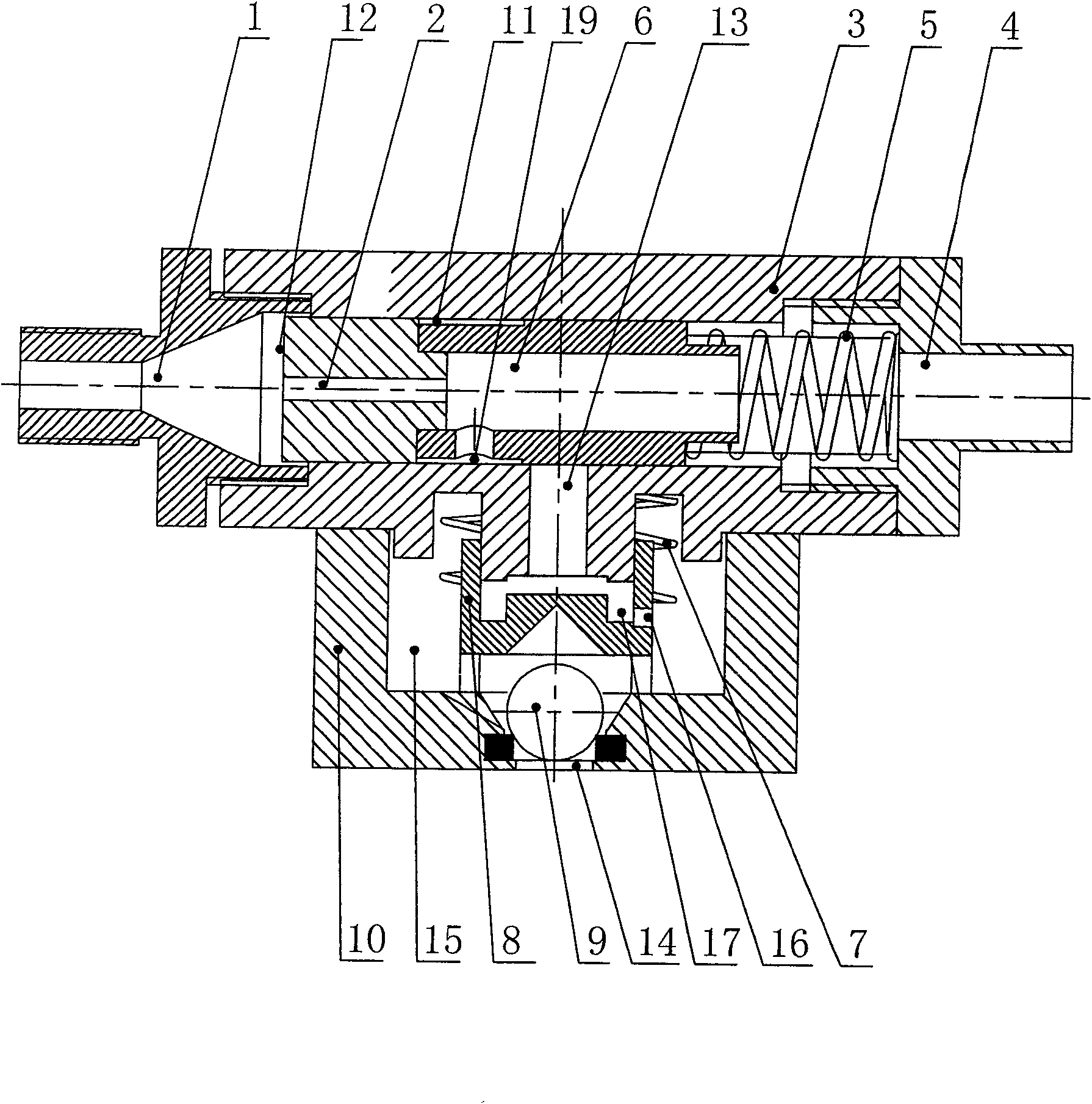

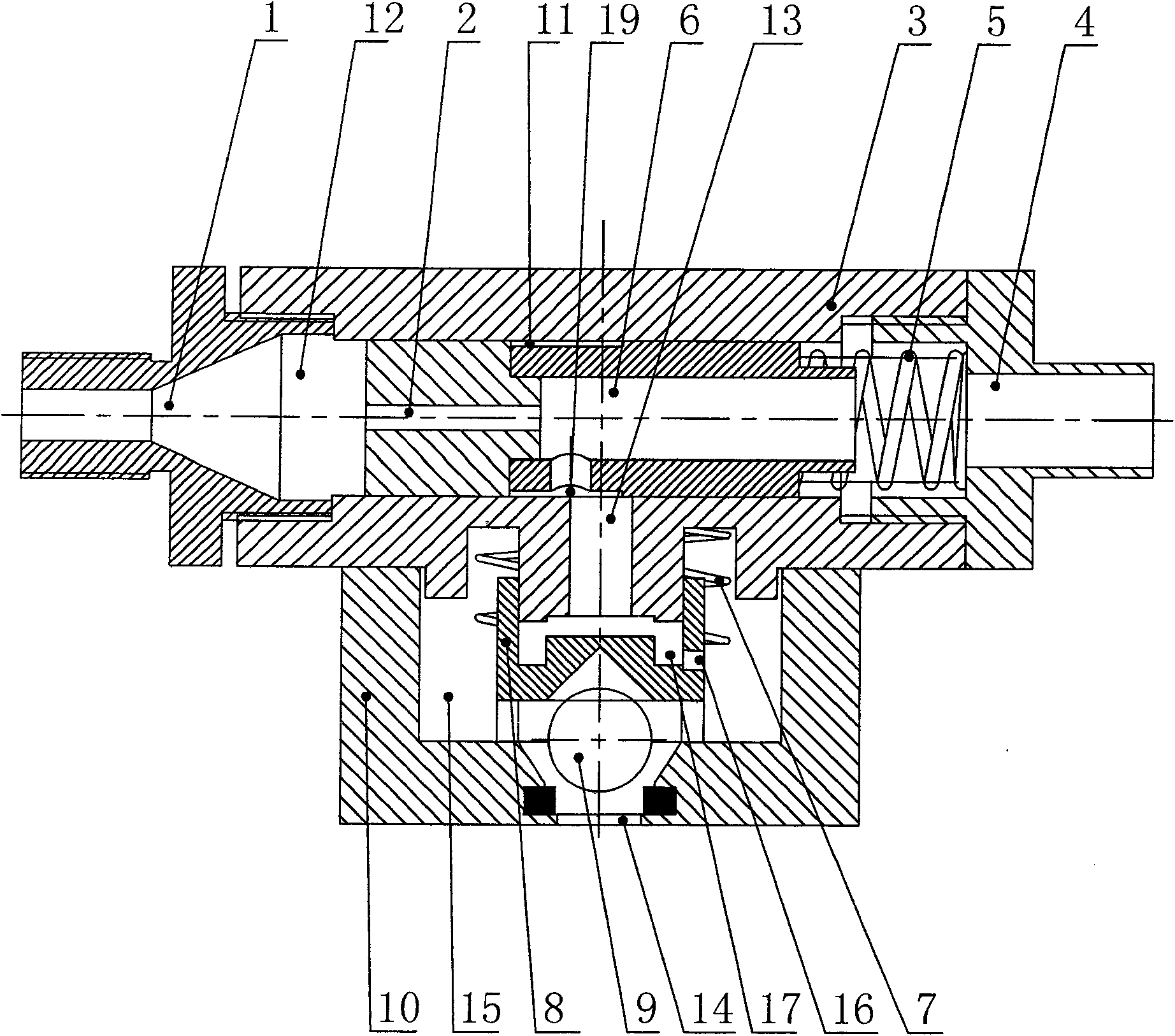

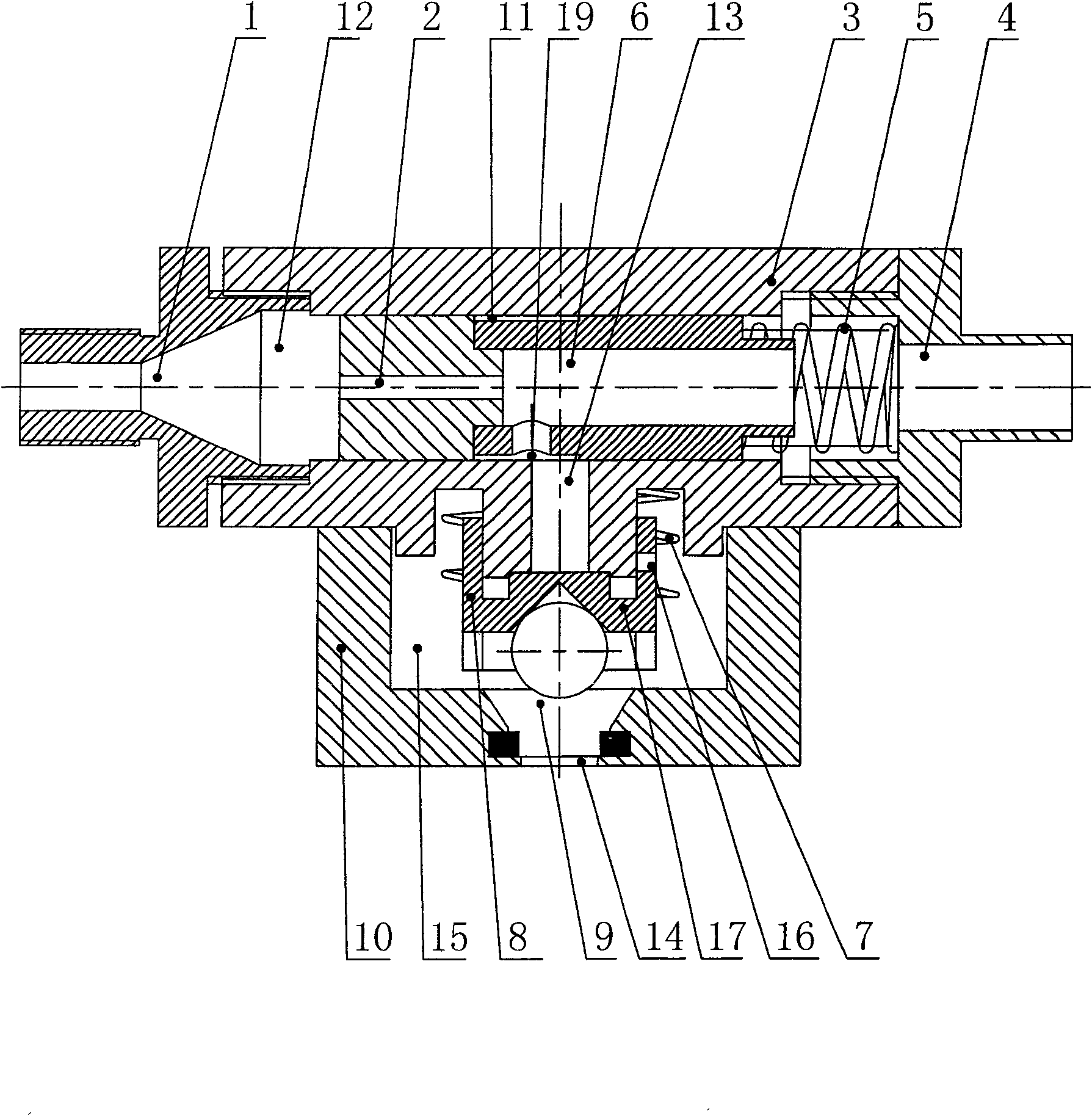

[0021] The structure of the present invention before vacuumizing is referring to figure 1 , an automatic reset leak-proof air injection system, including an air intake pipe 1 that can pass through compressed gas, an exhaust pipe 4 that communicates with the outside world, a hollow substrate 3 that is connected between the air intake pipe 1 and the exhaust pipe 4, and is arranged on the substrate 3, the negative pressure device and automatic reset device and the air-inducing device arranged under the base 3; wherein: the negative pressure device includes the nozzle 2 arranged in the base near the end of the intake pipe 1, and the nozzle 2 arranged in the base 3 near the exhaust pipe 4 The diffuser 6 at one end, the pressure chamber 12 arranged between the nozzle 2 and the inlet pipe 1, the inlet pipe 1, the pressure chamber 12, the nozzle 2, the diffuser 6 and the exhaust pipe 4 are sequentially connected to form the injection gas channel The inner diameter of the nozzle pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com