Mold for producing RPT sheet ring-pulls in cold stamping continuous progressive manner

A technology of cold stamping and sheet retention, applied in the field of production molds for pull tabs of cans, can solve the problems of reducing the area and being unusable, and achieve the effect of increasing the overall area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below in conjunction with the embodiment given with accompanying drawing, but embodiment does not constitute any limitation to the present invention.

[0034] The mold of the RPT retaining tab provided in this embodiment is a continuous progressive mold for cold stamping, and the continuous progressive production process of cold stamping is as follows: cutting process, concave process, edge trimming process, pre-rolling process, turning Edge process, forming process, scoring process; for the molds are: cutting die, punching die, trimming die, pre-rolling die, flanging die, forming die, scoring die; among them, trimming die, turning The side mold and forming mold are exactly the same as the traditional production mold with finger hole pull ring, and its structure description is omitted.

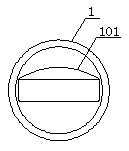

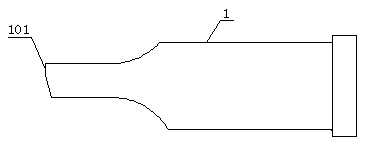

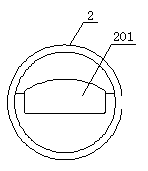

[0035] see figure 1 , figure 2 , the cutting die is composed of a cutting punch 1 and a cutting die 2, the top of the cutting punch 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com