Snap-in floating oil seal assembling tool and implementing method thereof

A floating oil seal and buckle-type technology, which is applied in the field of assembly tools for floating oil seals, can solve the problems of difficult tool assembly and disassembly, complex structure, uneven force, etc., and achieve the effects of convenient tool removal and installation, stable structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

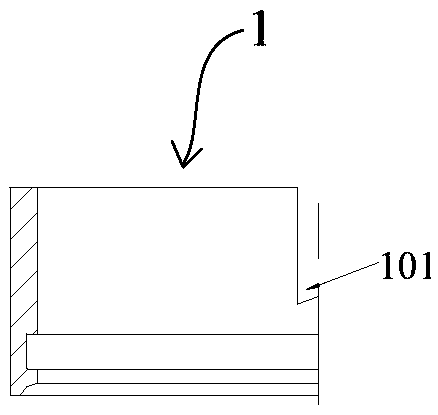

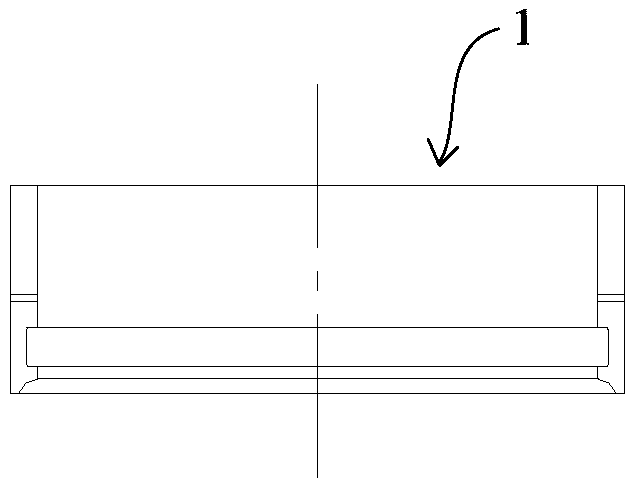

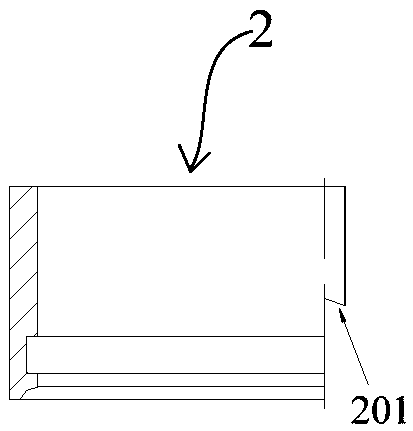

[0019] Such as Figure 1-6 As shown, the buckle-type floating oil seal assembly tool includes a left press sleeve 1, a right press sleeve 2, and a press cover 3. There is an N-type buckle-type male structure 101, and correspondingly, an N-type buckle-type female structure 201 is provided on the mating surface of the right pressure sleeve 2, and the left pressure sleeve 1 and the right pressure sleeve 2 are paired and combined to form a Complete ring structure, the upper ends of the left compression sleeve 1 and the right compression sleeve 2 are placed in the compression cover 3, and the two are combined into a whole through the compression cover 3, and the lower ends of the left compression sleeve 1 and the right compression sleeve 2 are provided for The contact portion attached to the O-ring is set as a rounded structure 4 .

[0020] Wherein, the N-type buckle-type male structure 101 includes two straight line segments parallel to the axis and an inclined segment connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com