Encasement mechanism with push board module

A push plate and carrier plate technology is applied in the field of packing mechanisms with push plate modules, which can solve the problems of wasting production resources and affecting the production efficiency of packaging operations, and achieves the effect of avoiding rigid collisions and promoting smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

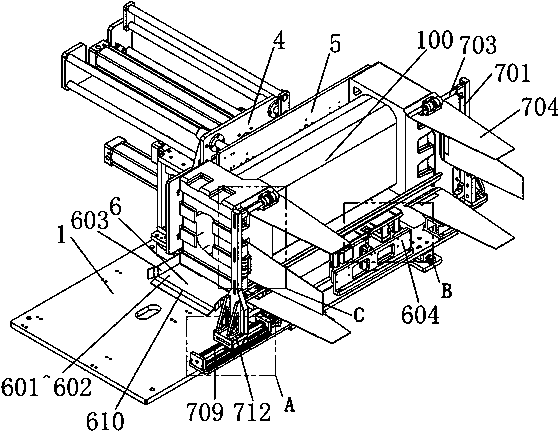

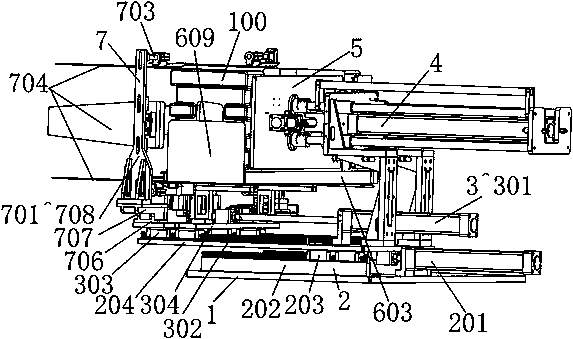

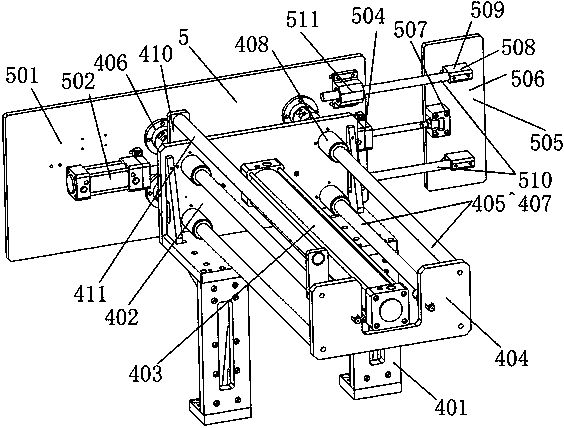

[0049]refer to Figure 1-Figure 7 , this embodiment provides a packing mechanism, including a bottom plate 1, a first mobile carrier module 2 slidably arranged on the bottom plate 1, and a second mobile carrier module slidably arranged on the first mobile carrier module 2 3. The push module 4 fixedly arranged on the first mobile carrier module 2, the push module 5 used in conjunction with the push module 4, the pallet module 6 and the guide module arranged on the second mobile carrier module 3 7;

[0050] The first mobile carrier module 2 includes a first cylinder 201 and a first slide rail 202 fixedly arranged on the bottom plate 1, a first slide block 203 slidably arranged on the first slide rail 202, and a first slide block 203 fixedly arranged on the first slide block. The first carrier plate 204 on the 203 and connected to the cylinder shaft of the first cylinder 201;

[0051] The second mobile carrier module 3 includes a second cylinder 301 and a second slide rail 302 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com