Can lid anti-dumping device

An anti-dumping and can lid technology, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as robotic arms being unable to complete, scratching, and dumping can lids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

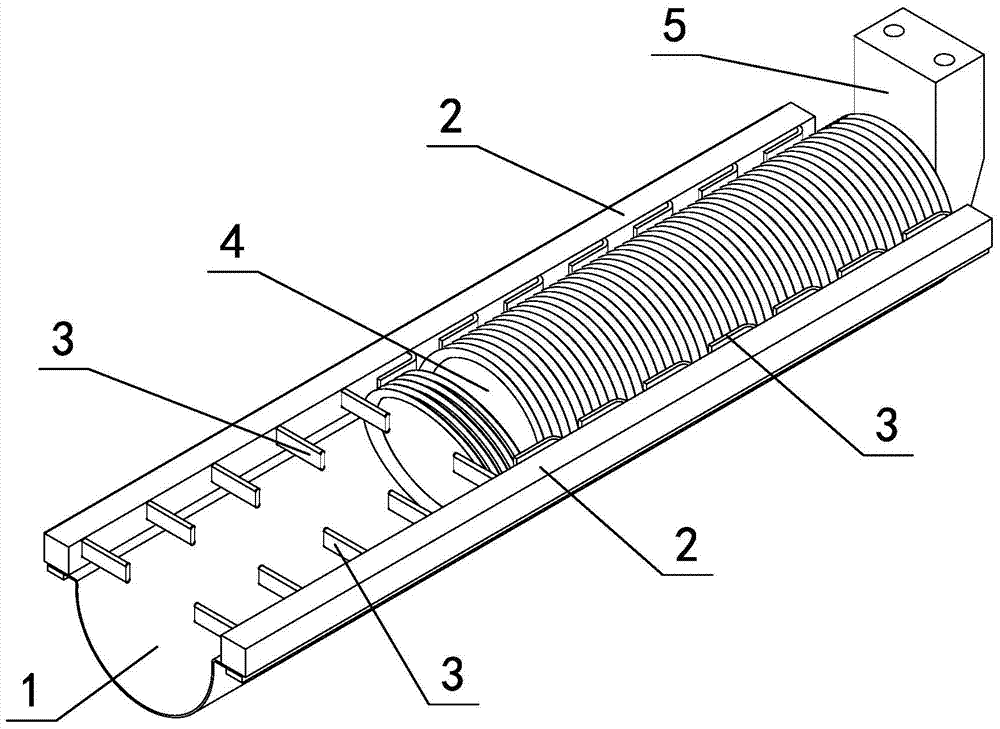

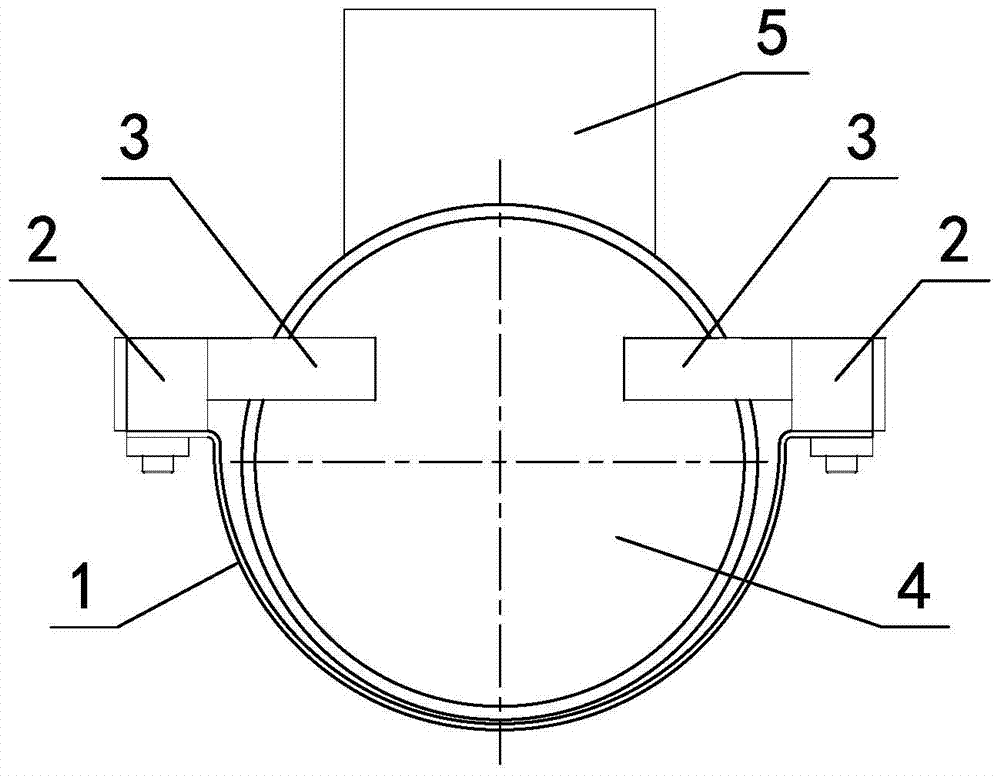

[0027] in such as figure 1 In the shown embodiment 1, a can lid anti-dumping device is arranged on the horizontal lid collection groove 1 of the can end production line, and the sheet-shaped can lids separated from each other are assembled into a cylindrical can lid 4 in the lid collection groove. The cross-section of the cover collection tank is U-shaped, and the notches on both sides of the cover collection tank are respectively provided with mounting seats 2 along the length direction of the cover collection tank. Cover strip 3, the cover strip is made of rubber or plastic material, the cover strip is horizontally arranged, one end of the cover strip is fixed with the mounting seat, the other end of the cover strip is suspended and extends into the cover collecting groove, and the cover The projected length of the suspended part of the strip on the cross section of the cover groove is 30 to 45% of the opening width of the cover groove, which is 40% in this embodiment; the d...

Embodiment 2

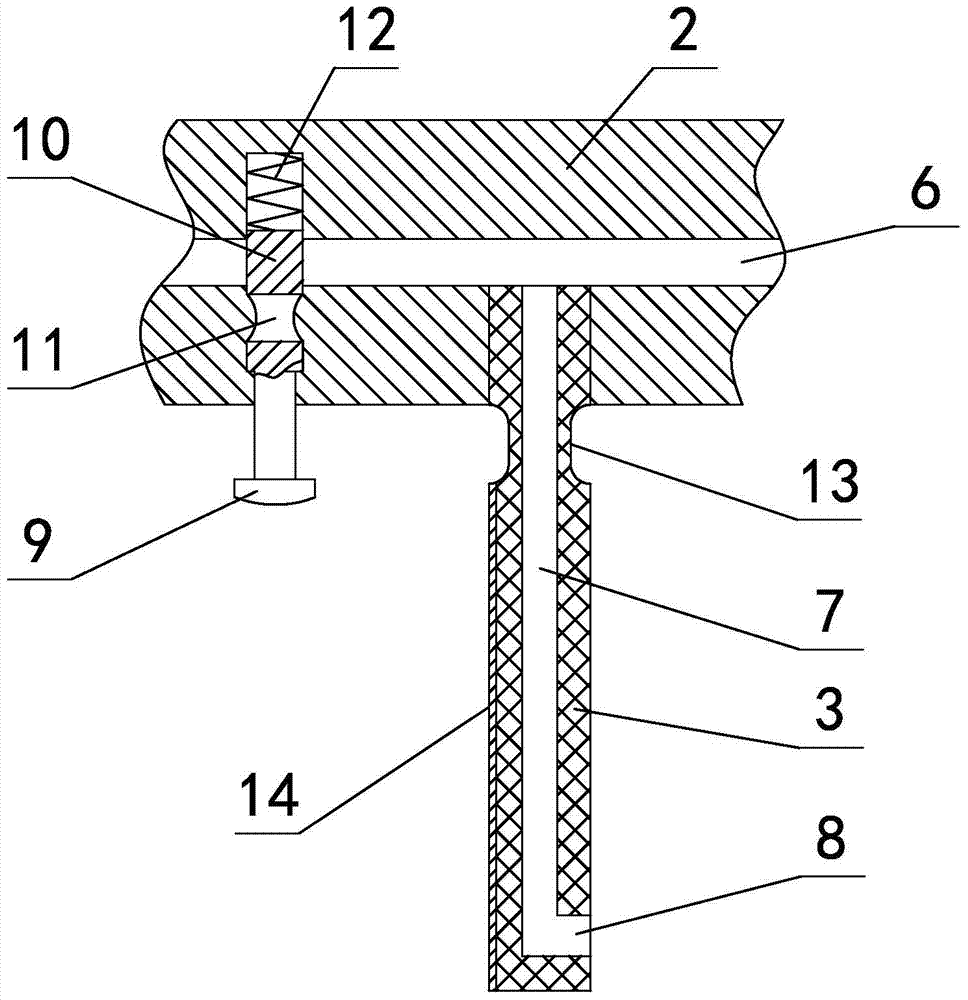

[0029] in such as Figure 5 In the shown embodiment 2, the tank cover anti-dumping device is provided with an air channel 6 connected to the air source in the length direction of the mounting seat (see image 3 , Figure 4), the cover bar is a hollow structure with an air path 7 connected to the air channel inside, and the air jet port 8 is provided at the suspended end of the cover bar, and the air jet port points to the cover groove before the cover bar is bent The upstream side of the flow direction of the can end (ie the incoming direction of the can end, see image 3 ), the side of the mounting seat facing the cover tank is provided with an airway switch 9 (see Figure 5 ), the airway switch is arranged between two adjacent cover strips and close to the upstream side cover strip in the flow direction of the cover tank cover, and the height of the airway switch is adapted to the height of the cover strip.

[0030] The airway switch of this embodiment includes a plunger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com