Molten glass stirring device, plate glass manufacturing device, molten glass stirring method, and plate glass manufacturing method

A technology of molten glass and stirring device, which is applied in the direction of glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., can solve the problems such as difficulty in obtaining the homogeneity of molten glass, and achieve high transparency, excellent homogeneity, and high flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

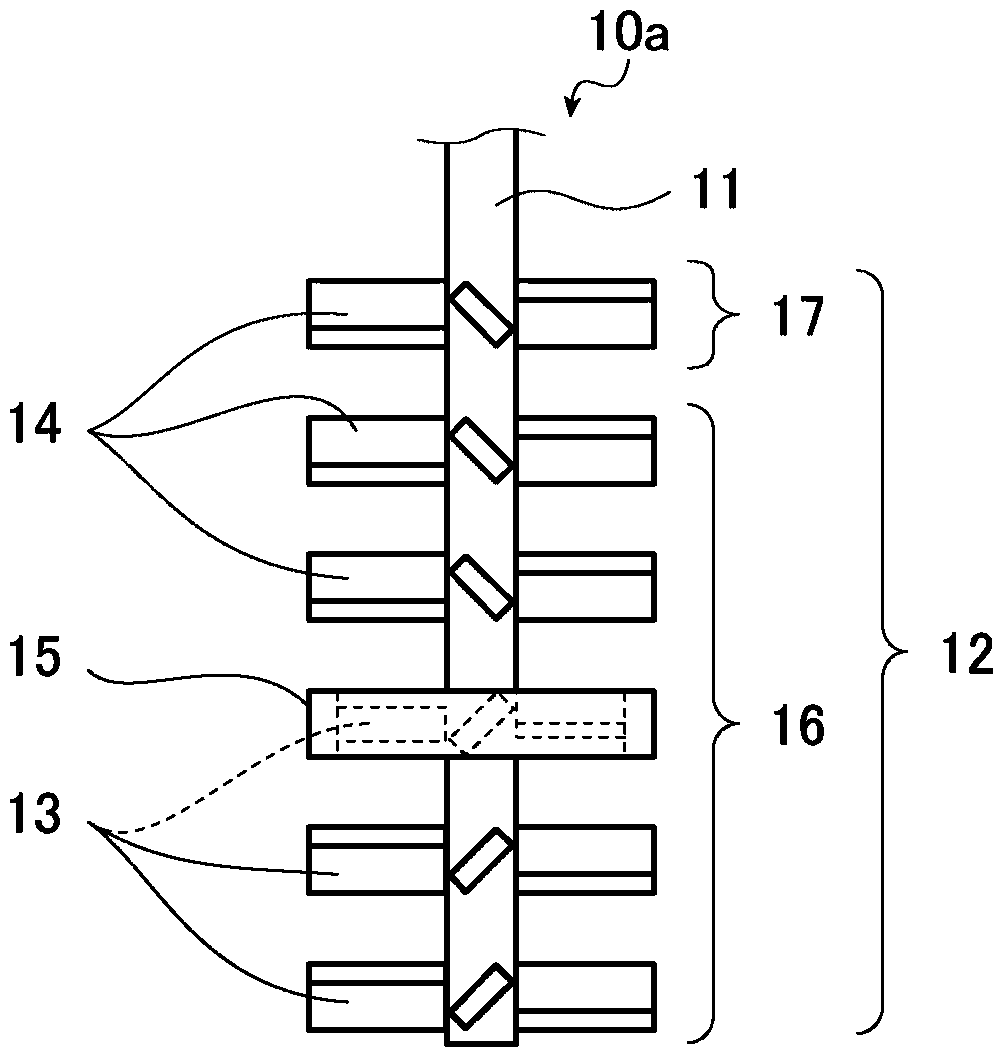

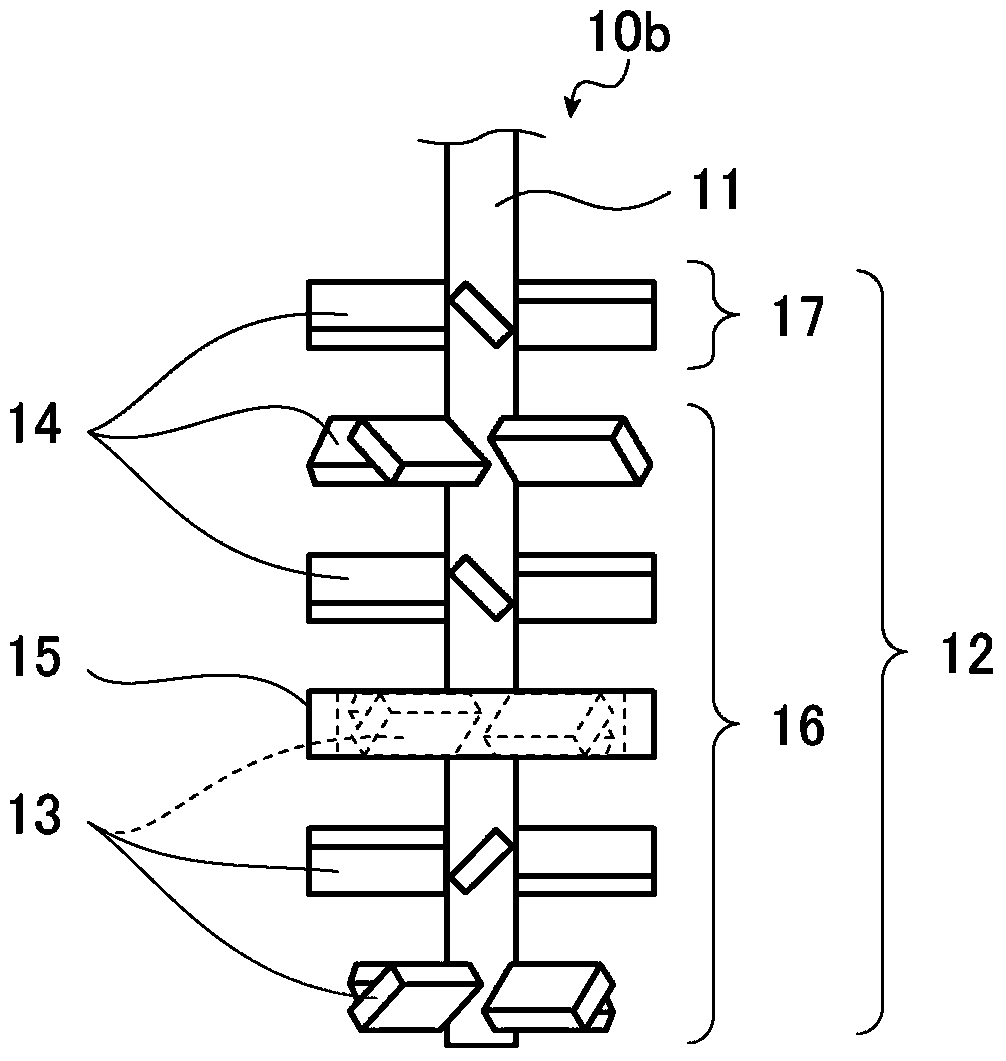

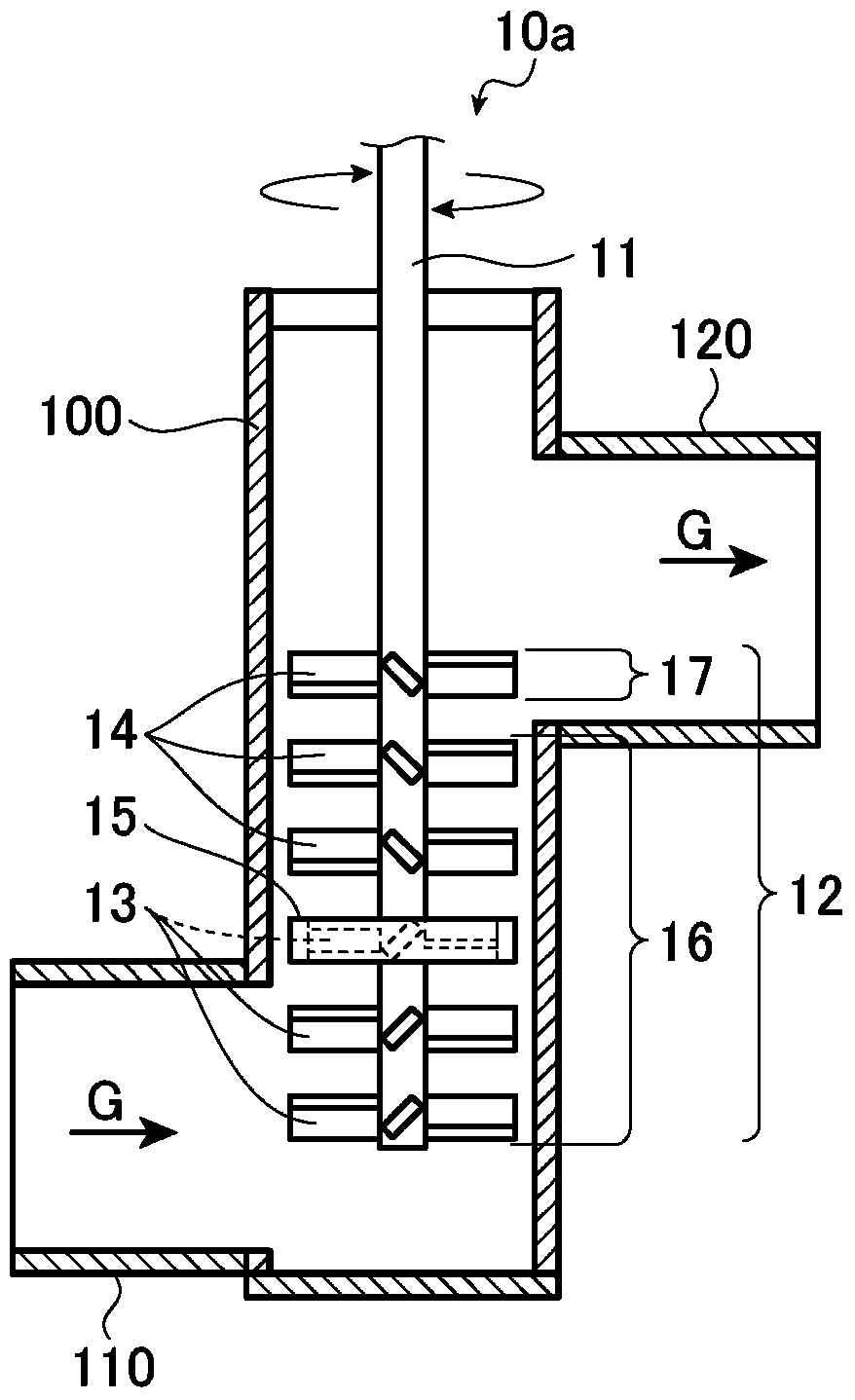

[0199] Will image 3 The shown molten glass stirring apparatus 10a of this invention was installed in the main pipe 100 of a molten glass conveyance pipe, and the behavior of the fluid at the time of stirring was evaluated. The dimensions of each part of the molten glass stirring device are as follows.

[0200] The maximum diameter D of the first stirring blade 13 and the second stirring blade 14 1 : 80mm

[0201] The outer diameter D of the annular blade 15 r : 80mm

[0202] Distance between the lower end of the annular blade 15 and the upper end of the branch pipe 110 on the upstream side: +10mm

[0203] Distance between the upper end of the annular blade 15 and the upper end of the branch pipe 110 on the upstream side: +30mm

[0204] Distance between the switching position of the stirring blade and the upper end of the branch pipe 110 on the upstream side: +45mm

[0205] The upward force F of the flow of molten glass produced by the first stirring blades 13 contained ...

Embodiment 2

[0210] Will Figure 4 The shown molten glass stirring apparatus 10c of this invention was installed in the main pipe 100 of a molten glass conveyance pipe, and the behavior of the fluid at the time of stirring was evaluated. The dimension of each part of the molten-glass stirring apparatus 10c is as follows.

[0211] The maximum diameter D of the first stirring blade 13 and the second stirring blade 14 1 : 80mm

[0212] The outer diameter D of the annular blade 15 r : 80mm

[0213] Distance between the lower end of the annular blade 15 and the upper end of the branch pipe 110 on the upstream side: +10 mm

[0214] Distance between the upper end of the annular blade 15 and the upper end of the branch pipe 110 on the upstream side: +30mm

[0215] Distance between the switching position of the stirring blade and the upper end of the branch pipe 110 on the upstream side: +80mm

[0216] The upward force F of the flow of molten glass produced by the first stirring blades 13 con...

Embodiment 3

[0234] Will Figure 8 The illustrated molten glass stirring device 40 was installed in the main pipe 100 of the molten glass conveyance pipe, and the behavior of the fluid when stirring was performed was evaluated.

[0235] The dimension of each part of the molten-glass stirring apparatus 40 is as follows.

[0236] The maximum diameter D of the first stirring blade 43 and the second stirring blade 44 1 : 80mm

[0237] The outer diameter D of the annular blade 45 r : 80mm

[0238] Distance between the lower end of the annular blade 45 and the upper end of the branch pipe 110 on the upstream side: +10 mm

[0239] Distance between the upper end of the annular blade 45 and the upper end of the branch pipe 110 on the upstream side: +30mm

[0240] Distance between the switching position of the stirring blade and the upper end of the branch pipe 110 on the upstream side: +45mm

[0241] The upward force F of the flow of molten glass produced by the first stirring blade 43 contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com