Stirring device for molten glass

A technology for molten glass and stirring device, which is applied in the direction of stirring device, mixer with rotary stirring device, glass furnace equipment, etc., can solve the problem that the effect of slippage suppression cannot be said to be sufficient, and achieves high transparency and excellent stirring effect. , the effect of high flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

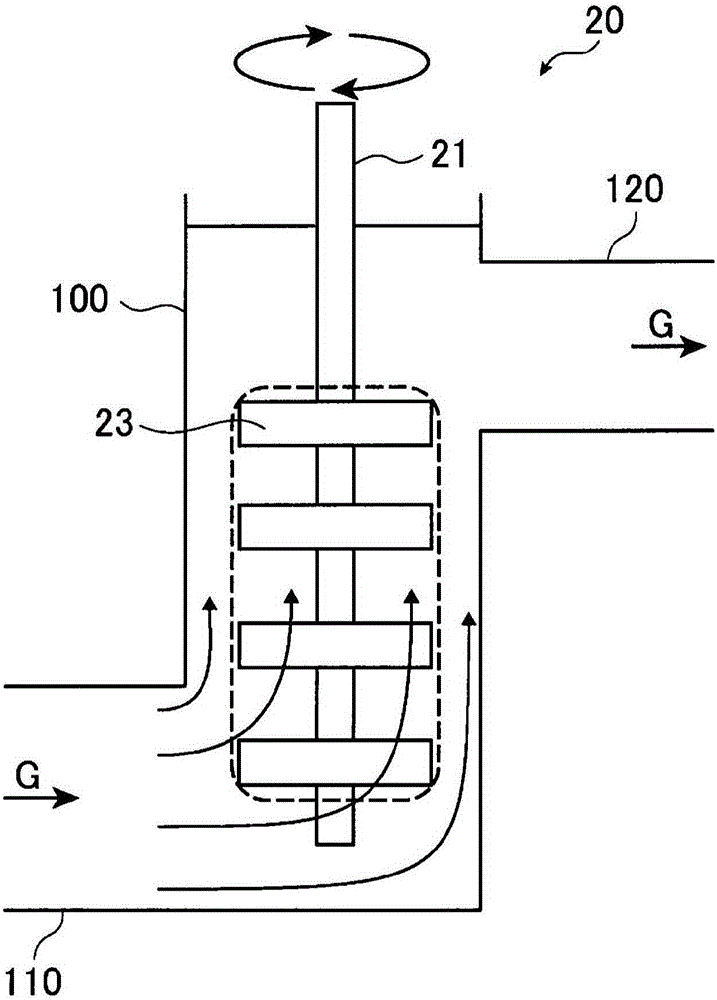

[0141] In this Example, evaluation was performed by simulating the behavior of the molten glass conveyed in the molten glass conveying tube.

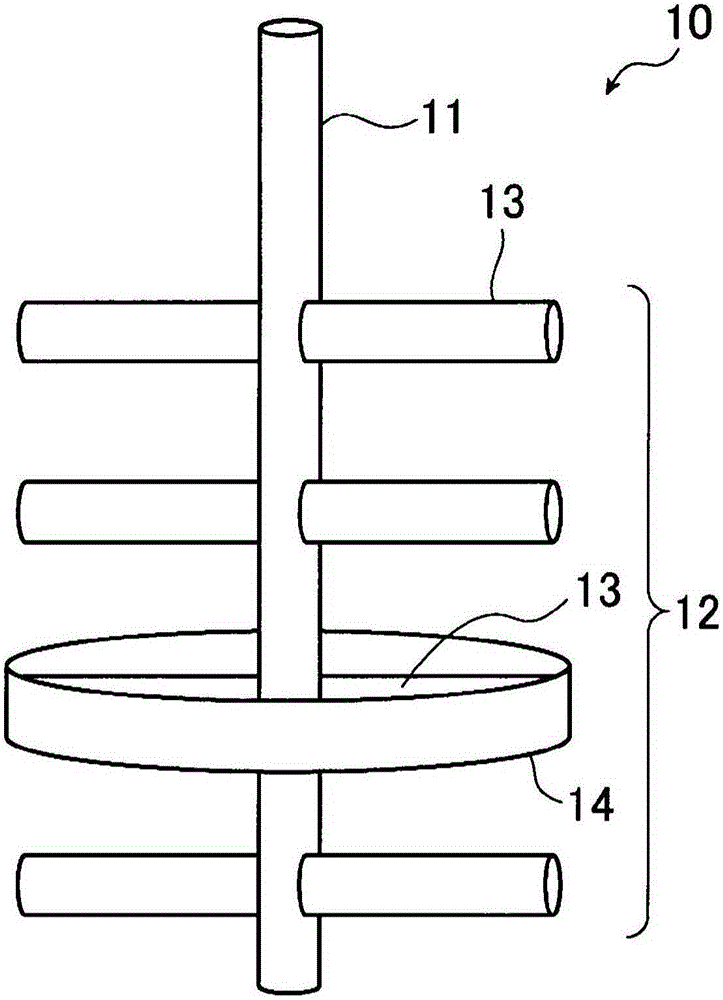

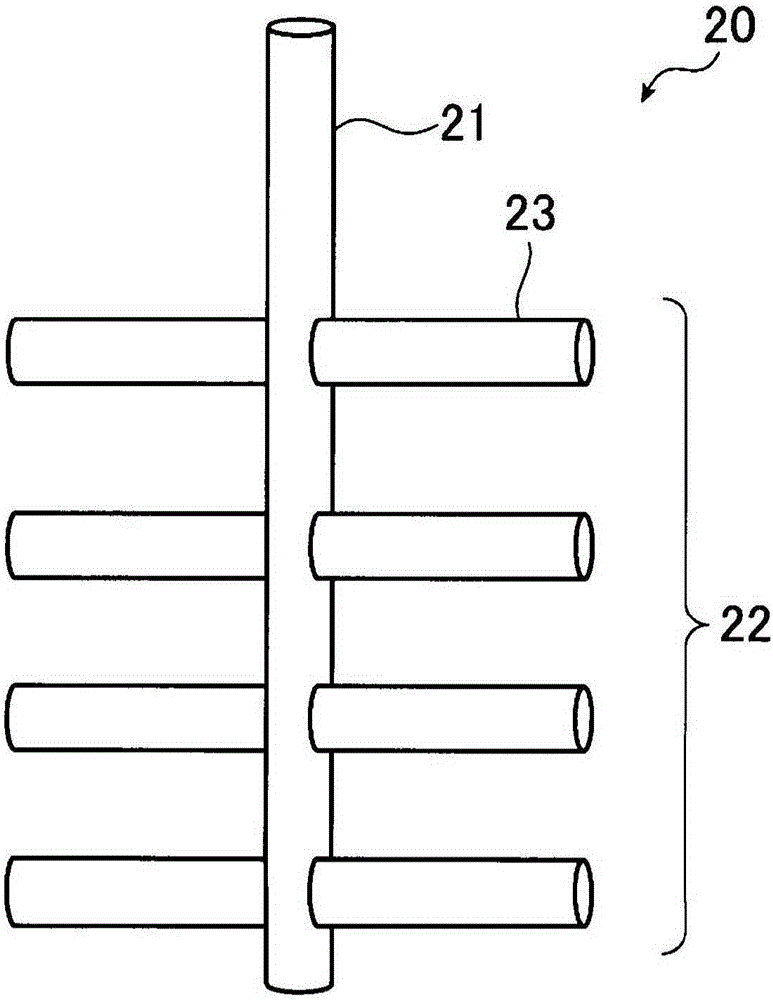

[0142] In this example, the evaluation image 3 the case shown, that is, configured with figure 2 The behavior of the molten glass flow in the molten glass conveying tube of the molten glass stirring device 20 shown, and evaluated Figure 4 the case shown, that is, configured with figure 1 The action of the molten glass flow in the molten glass conveyance pipe of the molten glass stirring apparatus 10. However, in order to clarify the difference caused by the presence or absence of the ring blade 14, the Figure 4The ring blade 14 in the shown molten glass stirring device 10 and the stirring blades 13 and image 3 In the illustrated molten glass stirring device 20, the stirring blade 23 located at the same position as the ring blade of the molten glass stirring device 10 in the axial direction of the center shaft 21 evaluated the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com