Steel used for third-generation nuclear power safety injection tank base plate and manufacturing method of steel

A safety injection box and substrate technology, which is applied to the steel for the third-generation nuclear power safety injection box substrate and its manufacturing field, can solve the problem that it cannot be used to manufacture the safety injection box shell substrate, etc., and achieves a controllable strength reduction range and a strength reduction range. Small and large margin effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples describe the present invention in more detail, and these examples are only descriptions of the best implementation modes of the present invention, and do not limit the scope of the present invention in any way.

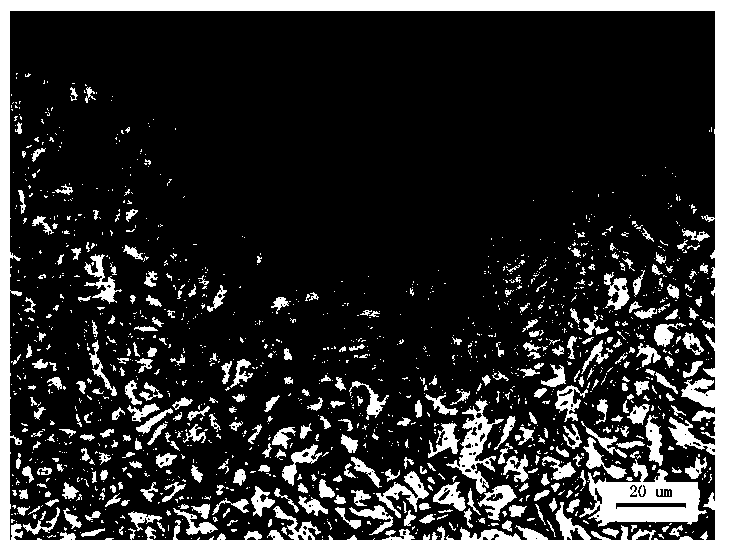

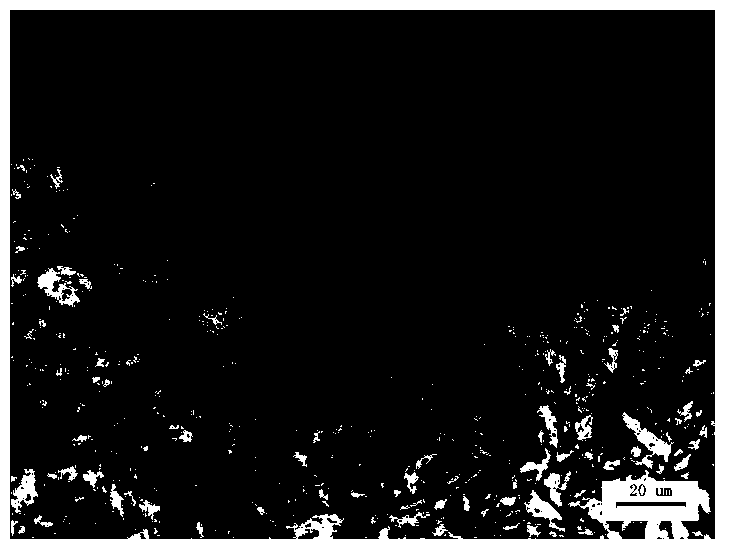

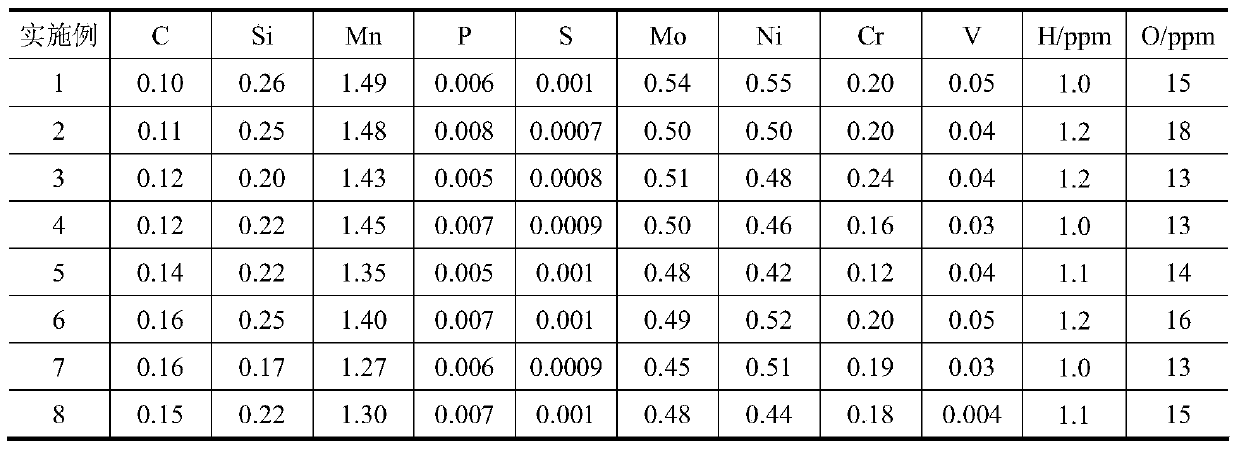

[0033] According to the chemical composition and production process of the present invention, the actual chemical composition of steel smelting of the present invention is shown in Table 1, the actual process of rolling and heat treatment is shown in Table 2, the physical performance test results are shown in Table 3, and the quenched and tempered state structure diagram of Example 4 is shown in Table 1. figure 1 , Example 4 quenching and tempering + simulated post-weld heat treatment structure diagram see figure 2 .

[0034] Table 1 Steel smelting actual chemical composition (wt%) of the present invention

[0035]

[0036] Table 2 steel rolling and heat treatment actual process of the present invention

[0037]

[0038] Table 3 Ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com