Construction process of back-bolted insulation and decoration integrated panel system

A construction process and back-bolt technology, which is applied in the field of the construction process of the back-bolt thermal insulation and decoration integrated system, can solve the problems of difficult installation of fixed parts, damage to flatness, and inability to install, avoid cold bridges, and facilitate the adjustment of flatness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

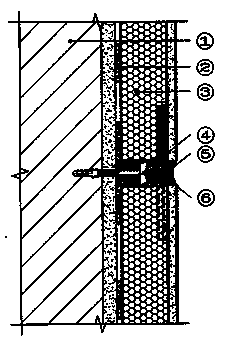

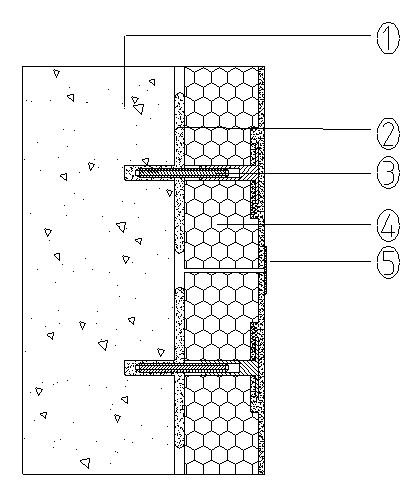

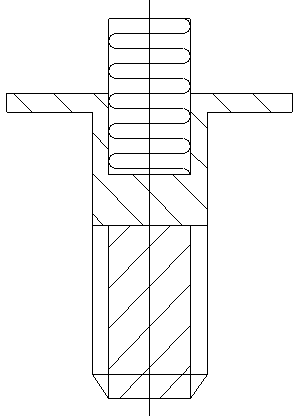

[0037] Combine below figure 2 The basic structure of the integrated back-bolt thermal insulation and decoration panel system is illustrated with examples to illustrate the implementation method. get ready figure 2 middle Thermal insulation and decoration integrated board, Bonding mortar, image 3 The marker shown, Figure 4 Shown back bolt screw and other general construction tools and auxiliary materials. Base wall After passing the inspection and reaching the national intermediate plastering standard, first draw or bounce the horizontal line, vertical line and starting line to determine the plan of the plank. Then install the Yin and Yang corner strips around the corners of the building and the windows, and install the starting strips on the starting horizontal line. Then according to the layout diagram, round the integrated board or cut the integrated board, image 3 The marker shown is installed on the back of the integrated board and connected to the embedded parts i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com