Multi-parking-space double-layer parking equipment with one layer of lifting car carrying boards

A double-deck parking and car-carrying board technology, which is applied in the direction of buildings, building types, and buildings where cars are parked, can solve problems such as complex mechanisms, difficult multi-layer applications, and poor safety, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

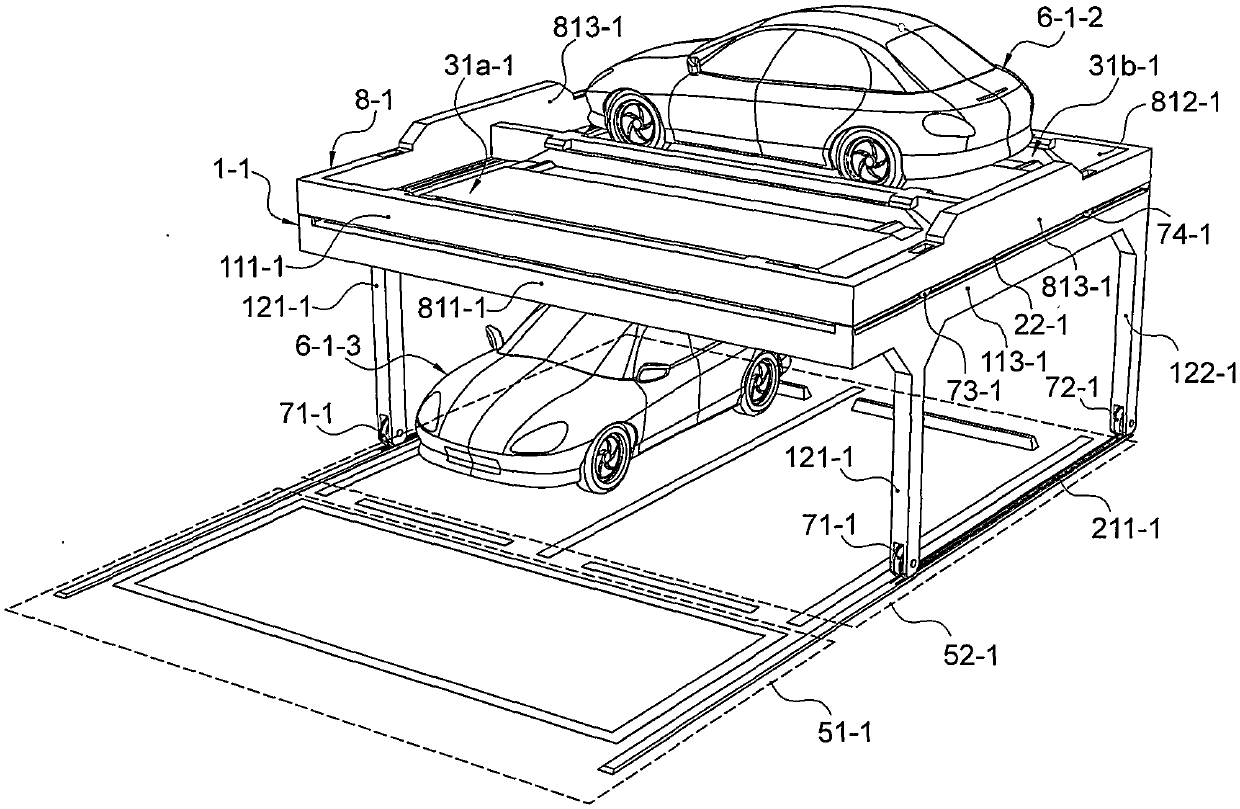

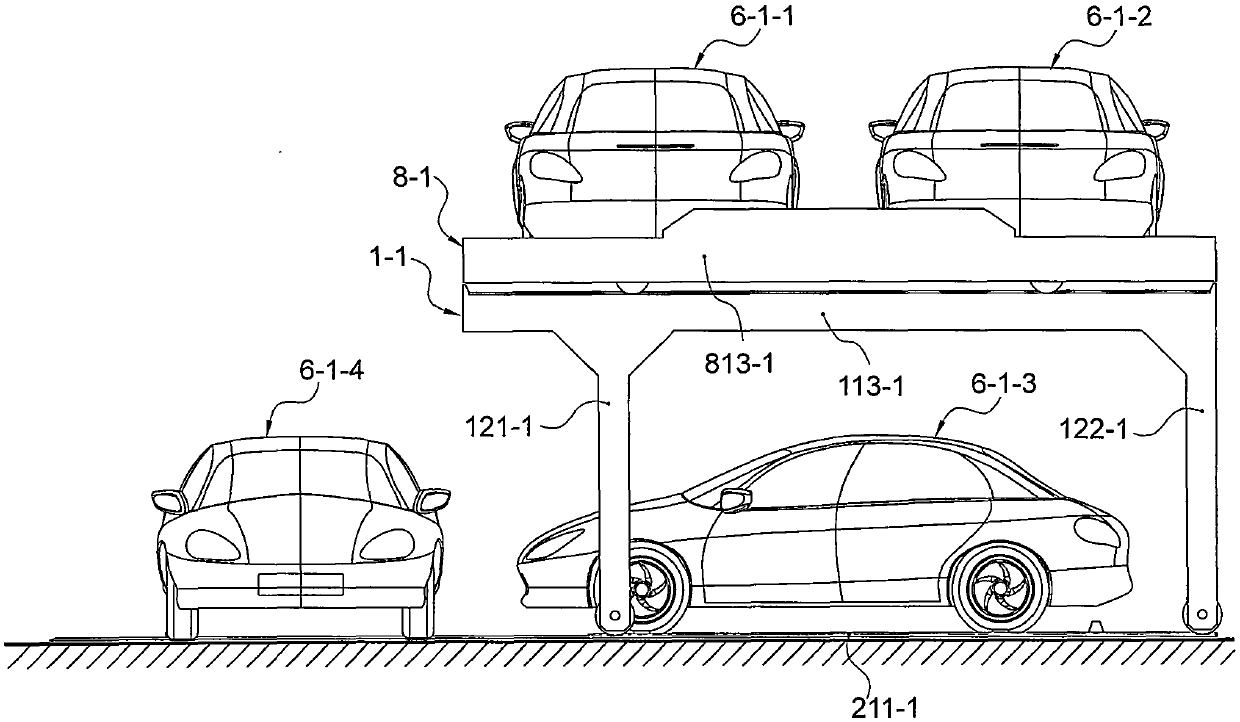

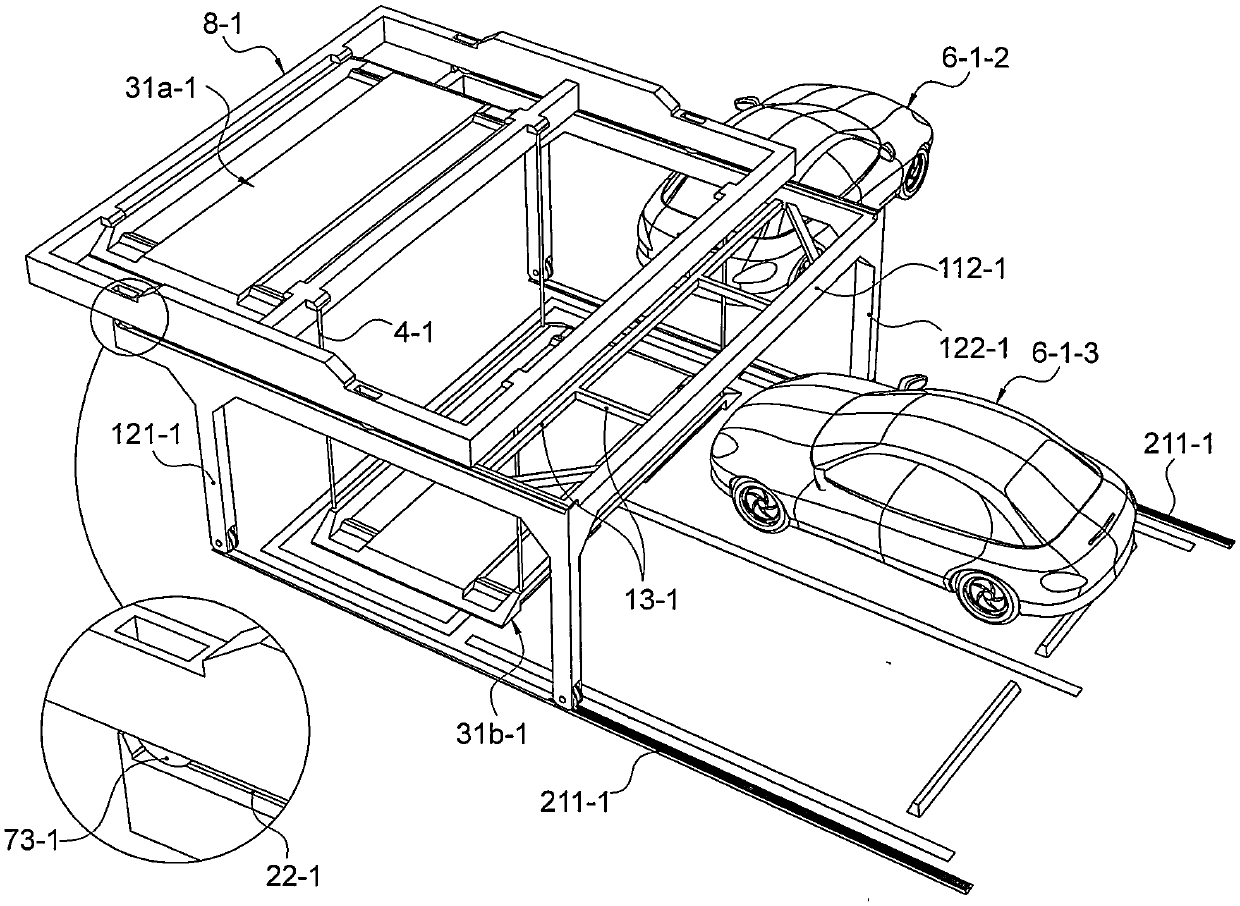

[0059] Example 1 as Figure 1-6 shown. This is a kind of double-deck four parking space parking equipment implementation scheme designed according to the basic principle of the present invention. The device includes a traversing frame 1-1 with a hollow frame structure, which is formed by connecting the front main beam 111-1, the rear main beam 112-1, and the left and right side main beams 113-1.

[0060] Below the left and right main beams 113-1 of the traverse frame 1-1, there are two left and right front outriggers 121-1 with bottom wheels 71-1 and two left and right rear outriggers 122-1 with bottom wheels 72-1 . The rear outrigger bottom wheel 72-1 runs on the track 211-1 on the ground on the left and right sides of the vehicle parking area 52-1. With the help of the bottom wheels of the legs, the traversing frame 1-1 located in the vehicle parking area 52-1 can go straight forward to the vehicle access area 51-1 according to the above-mentioned track 211-1.

[0061] T...

Embodiment 2

[0067] Example 2 as Figure 7-17 shown. This is a kind of double-deck 6-space parking equipment implementation scheme designed according to the basic principle of the present invention and suitable for arrangement in underground parking garages. The equipment includes a front main beam 111-2, a rear main beam 112-2, left and right side main beams 113-2 and two traversing frame top beams 114-2 at the top. There are two left and right front outriggers 121-2 with bottom wheels 71-2 under the left and right ends of the front main beam 111-2 of the traverse frame 1-2, and there are belt bottom legs under the left and right ends of the rear main beam 112-2. The left and right rear outriggers 122-2 of the wheel 72-2. Each girder and supporting legs are connected to each other to form a traversing frame 1-2 with a door-shaped hollow frame structure (see Figure 7 ).

[0068] The rear leg bottom wheel 72-2 of the traversing frame runs on the track 211-2 on the left and right sides ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap