Inspecting device

A technology of inspection device and detection part, which is applied in the direction of electronic circuit testing, etc., can solve the problem of positional deviation of substrate and pressing part, and achieve the effect of suppressing positional deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

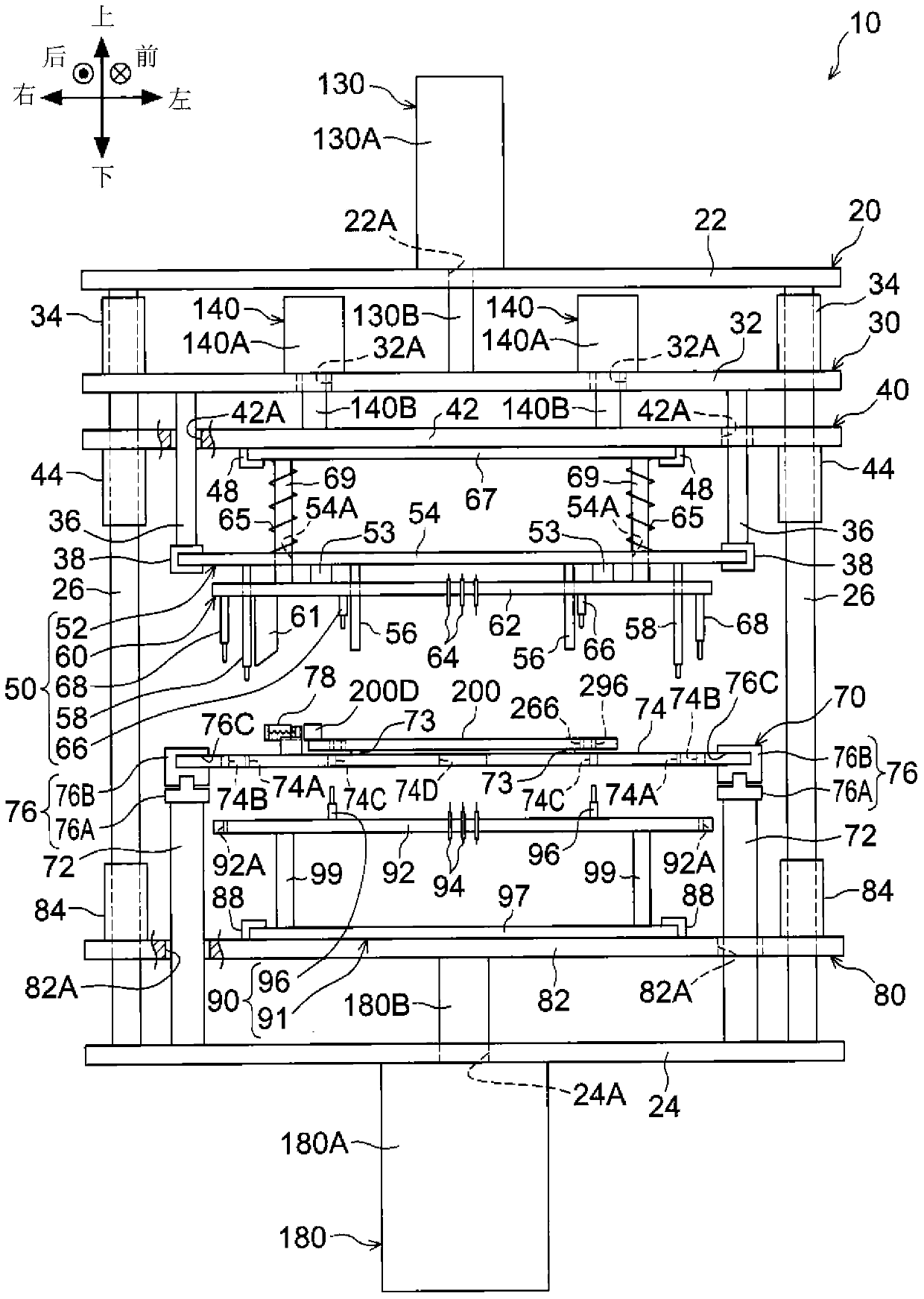

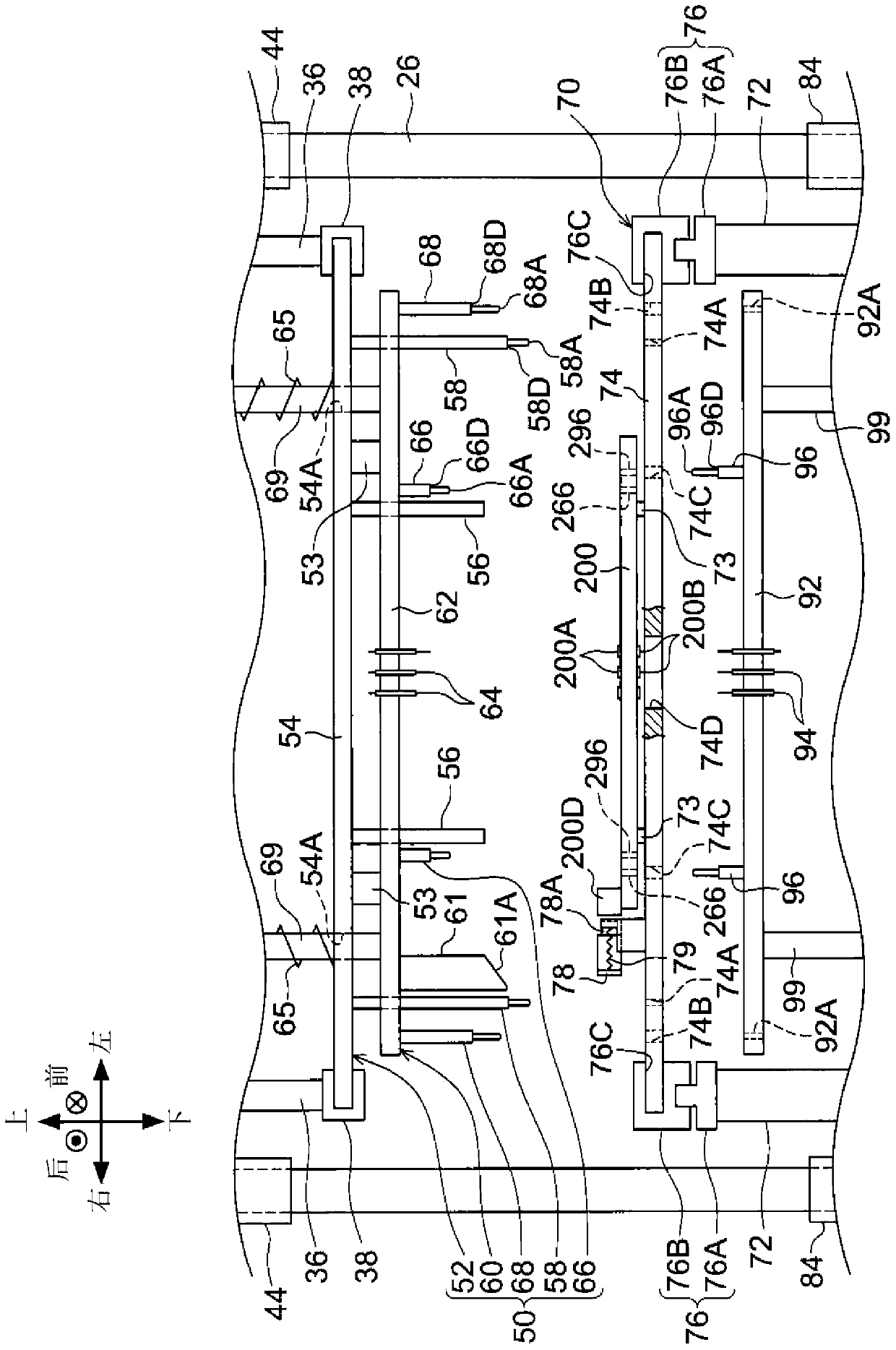

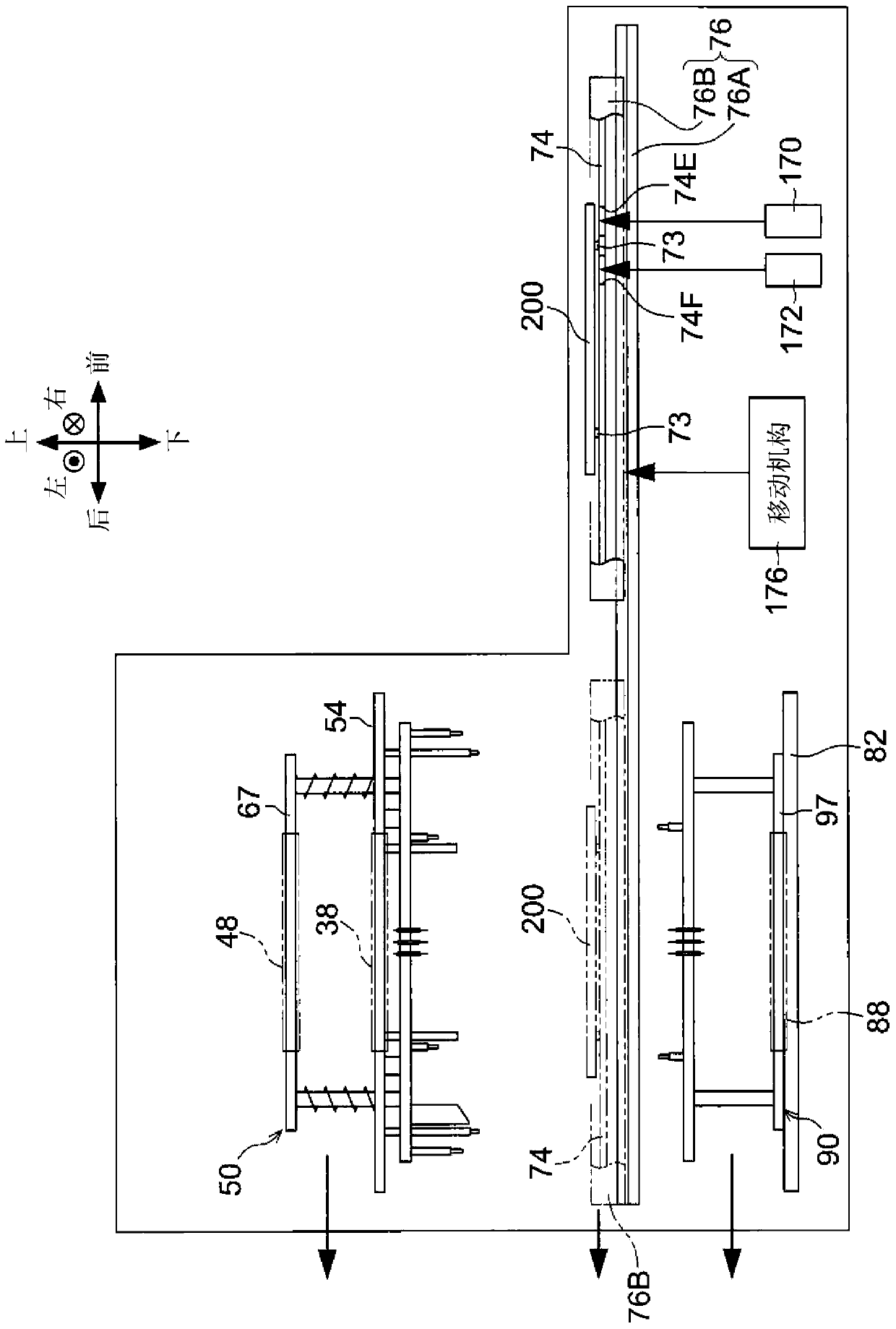

[0030] Hereinafter, an example of embodiment of the present invention will be described based on the drawings.

[0031] (Structure of inspection device 10)

[0032] First, the configuration of the inspection device 10 will be described. figure 1 It is a rear view showing the structure of the inspection apparatus 10 of this embodiment. In addition, the front of the device, the rear of the device, the right of the device, the left of the device, the upper part of the device, the lower part of the device used in the following description, and the arrow directions (front, rear, right, left, up, down) shown in the drawings correspond. In addition, the symbols with "x" described in "○" in the figure represent arrows that go from the front to the back of the page. The symbols with "·" written in "○" in the figure represent arrows directed from the back side of the paper.

[0033] In the present embodiment, in the inspection apparatus 10, the side accessed by workers who perform t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com