Workpiece unit and method for producing same

A technology of processed objects, applied in medical science, tooth filling, orthodontics, etc., can solve the problems of position deviation and the inability to process the processed body into a preset shape, etc., and achieve the goal of suppressing position deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

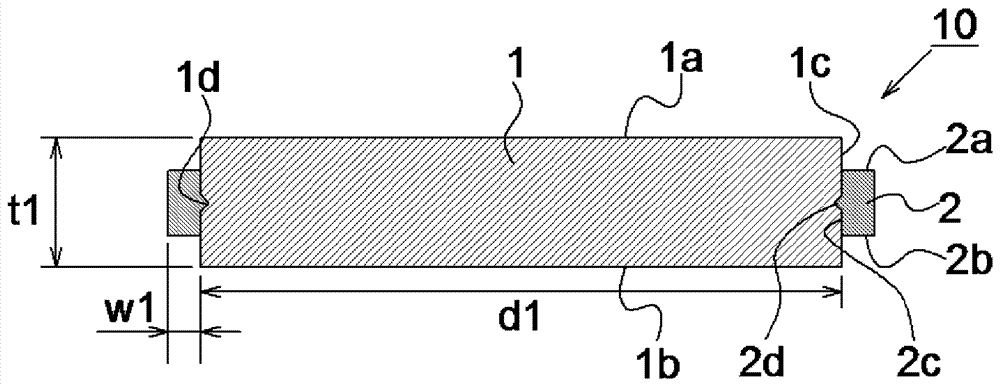

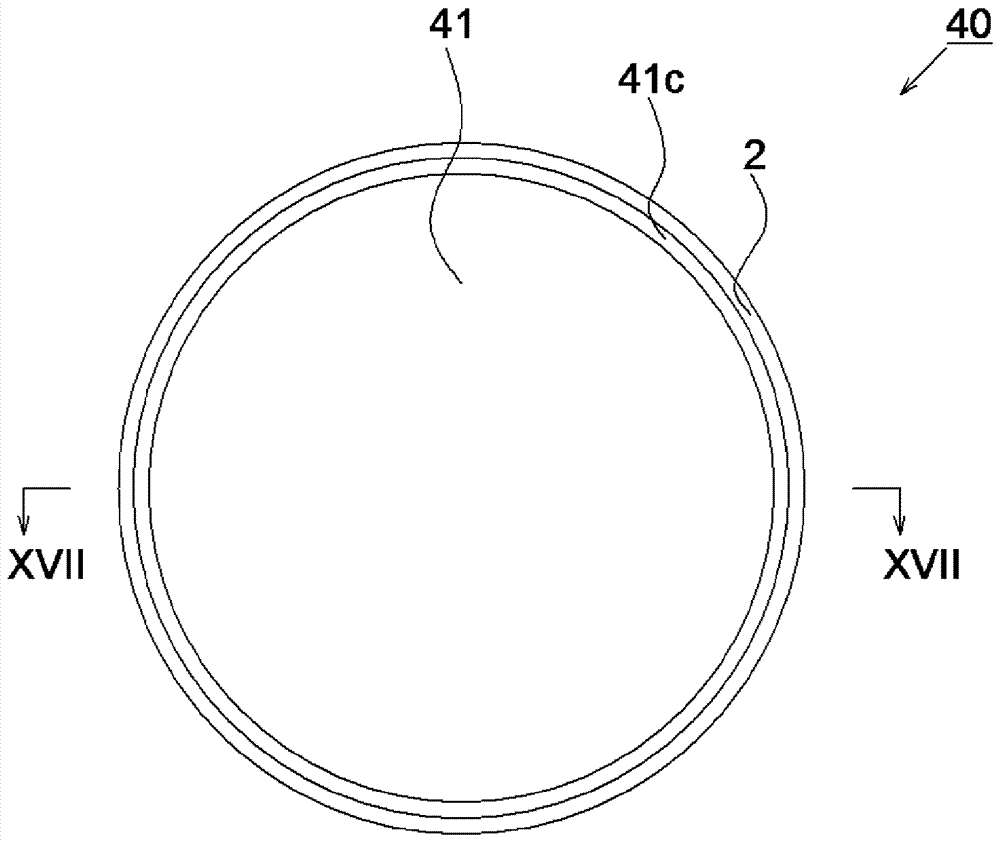

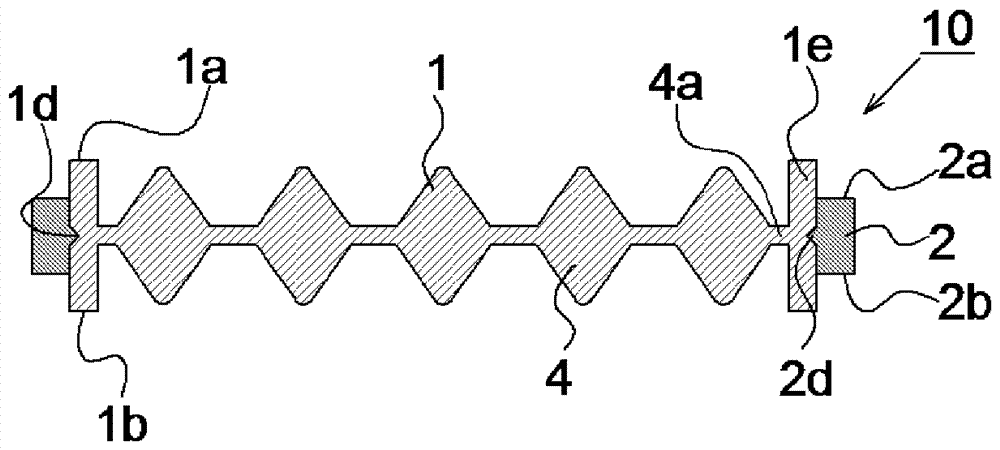

[0050] In the following description, reference numerals are added for understanding of the invention, and are not intended to be limited to the illustrated form. In each embodiment, the same code|symbol is attached|subjected to the same element. The dimensions and dimensional ratios of the drawings are not intended to be limited to those shown in the drawings.

[0051] Preferred aspects of each of the above-mentioned technical means are described below.

[0052] According to a preferred aspect of the above-mentioned first technical means, the first positioning portion has a shape of a concave portion or a convex portion. The second positioning portion has a shape fitted or engaged with the first positioning portion. At least a part of one of the first positioning part and the second positioning part fits or engages with at least a part of the other.

[0053] According to a preferred aspect of the above-mentioned first technical means, one of the first positioning portion an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com