Honeycomb filter

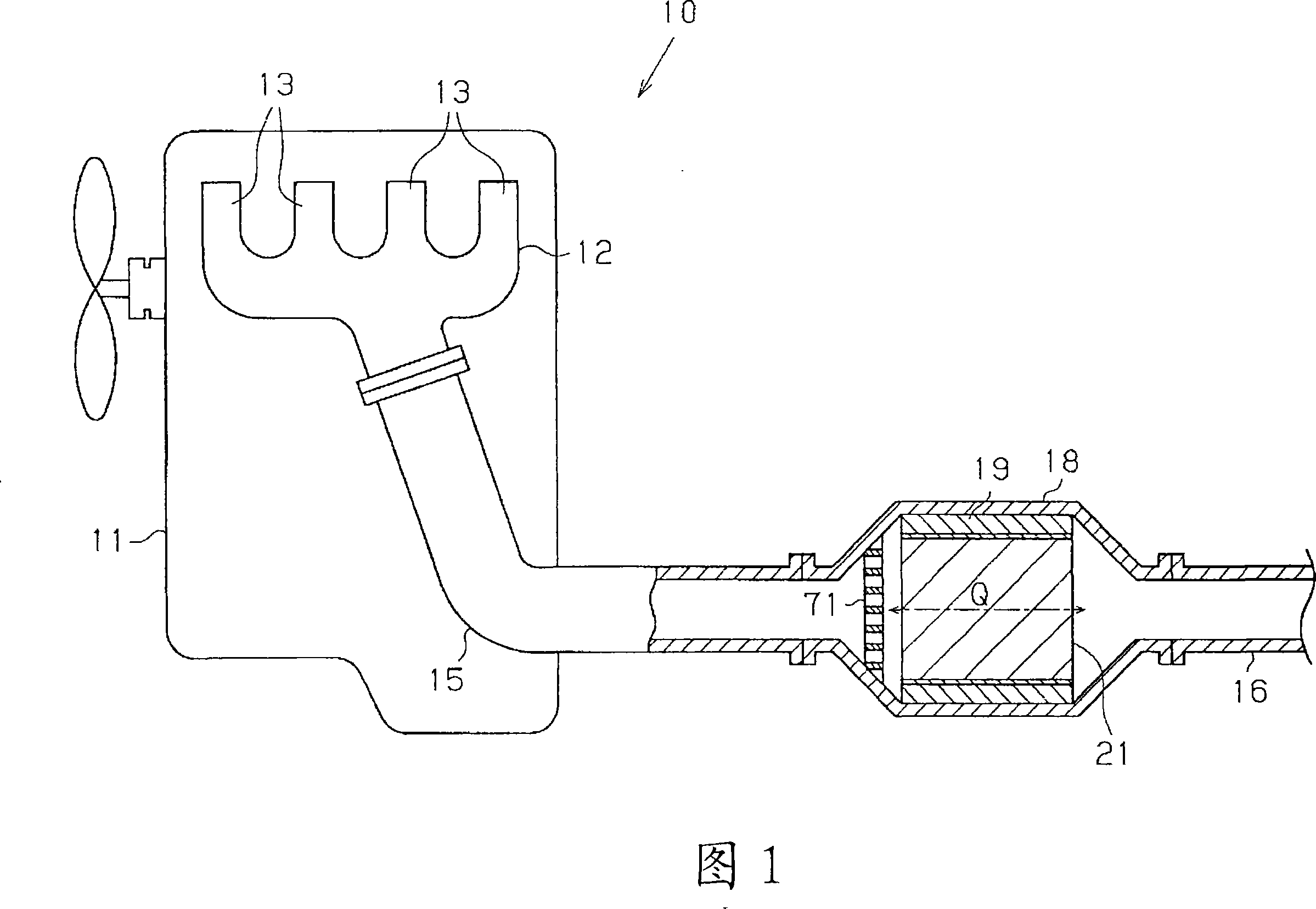

A filter, honeycomb technology, applied in filtration separation, dispersed particle filtration, machine/engine, etc., can solve the problems of exhaust gas leakage, filter performance reduction, exhaust gas purification efficiency reduction, etc., to achieve high heat resistance and strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0090] Next, test examples and comparative examples of the present invention will be described.

[0091]

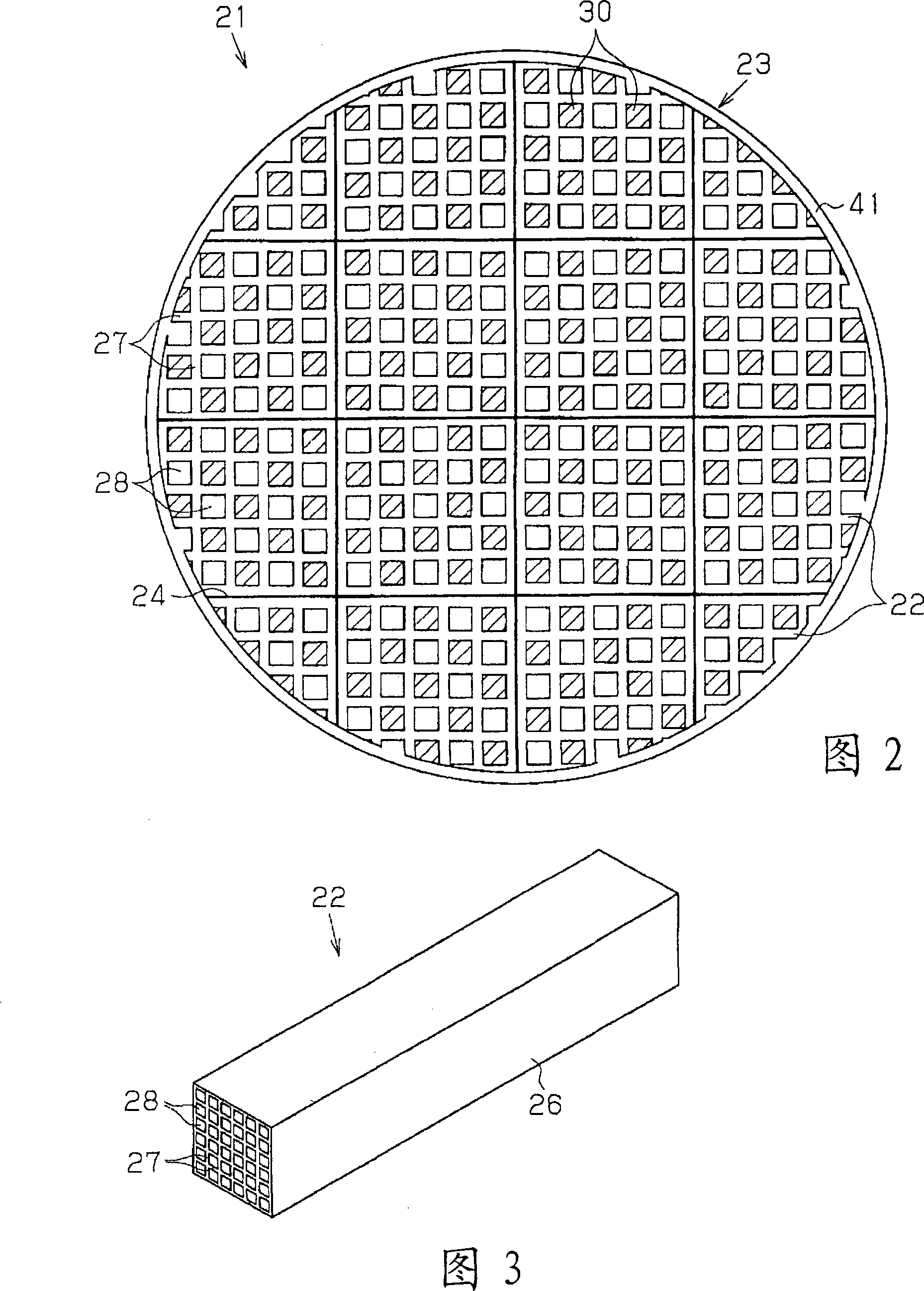

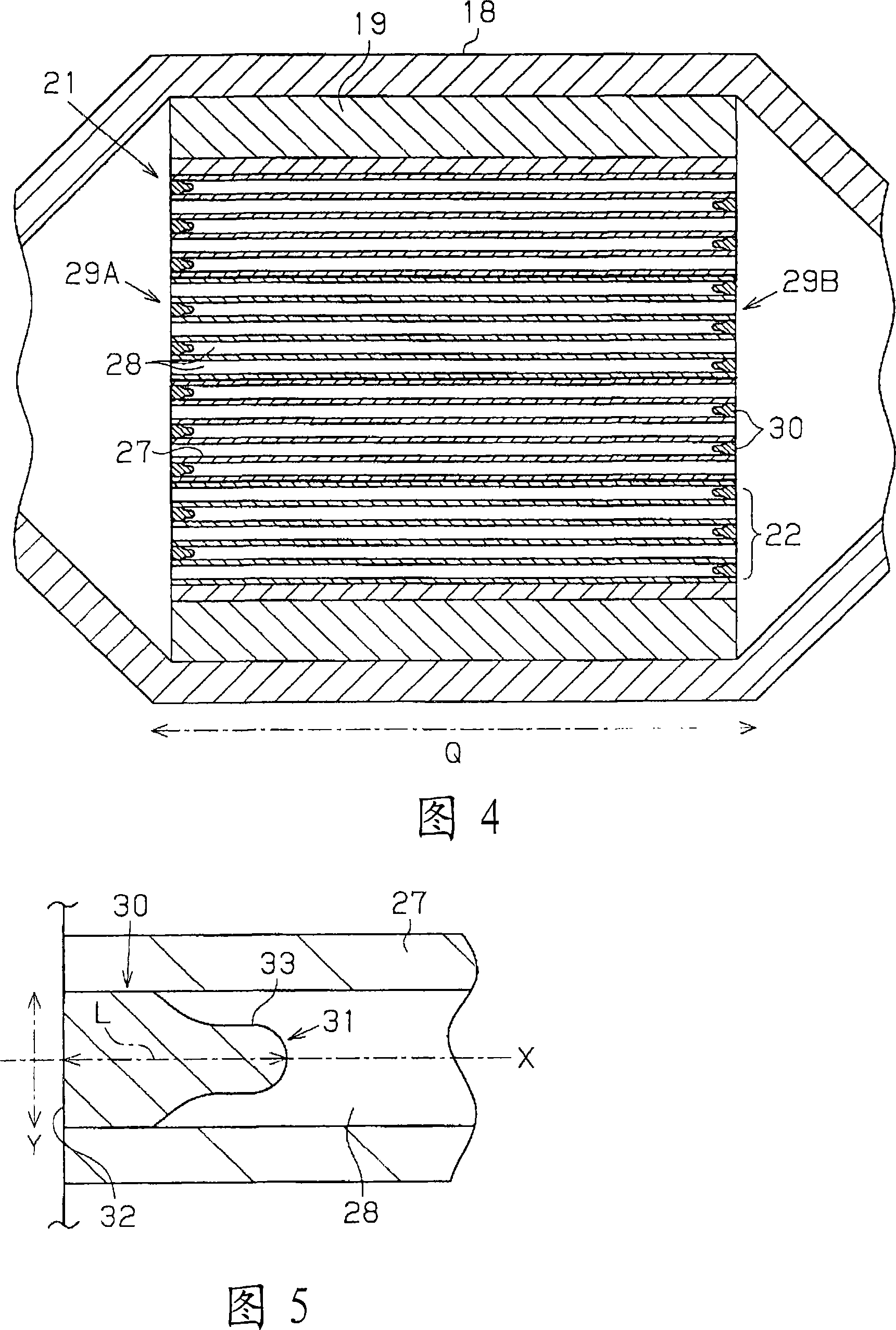

[0092] First, 7000 parts by weight of α-type silicon carbide powder with an average particle diameter of 10 μm and 3000 parts by weight of α-type silicon carbide powder with an average particle diameter of 0.5 μm were wet-mixed, and an organic binder (methyl 570 parts by weight of cellulose) and 1770 parts by weight of water were stirred to obtain a mixed composition. 330 parts by weight of a plasticizer (manufactured by NOF Corporation, Unilube (registered trademark)) and 150 parts by weight of a lubricant (glycerin) were added to this mixed composition, and after further stirring, extrusion molding was performed to obtain Prismatic preform shown in FIG. 3 .

[0093] Next, the preform is dried using a microwave dryer or the like to obtain a dried ceramic body. Fill the sealing body paste into the opening of the predetermined cell. After drying it with a dryer, degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com