Stator winding hoisting device

A hoisting device and stator winding technology, which is applied in the direction of prefabricated winding embedded in the motor, etc., can solve the problems of time-consuming and labor-intensive installation, difficulty in installing the stator winding, easy damage to the enameled wire of the stator winding coil, etc., and achieve the effect of preventing damage and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

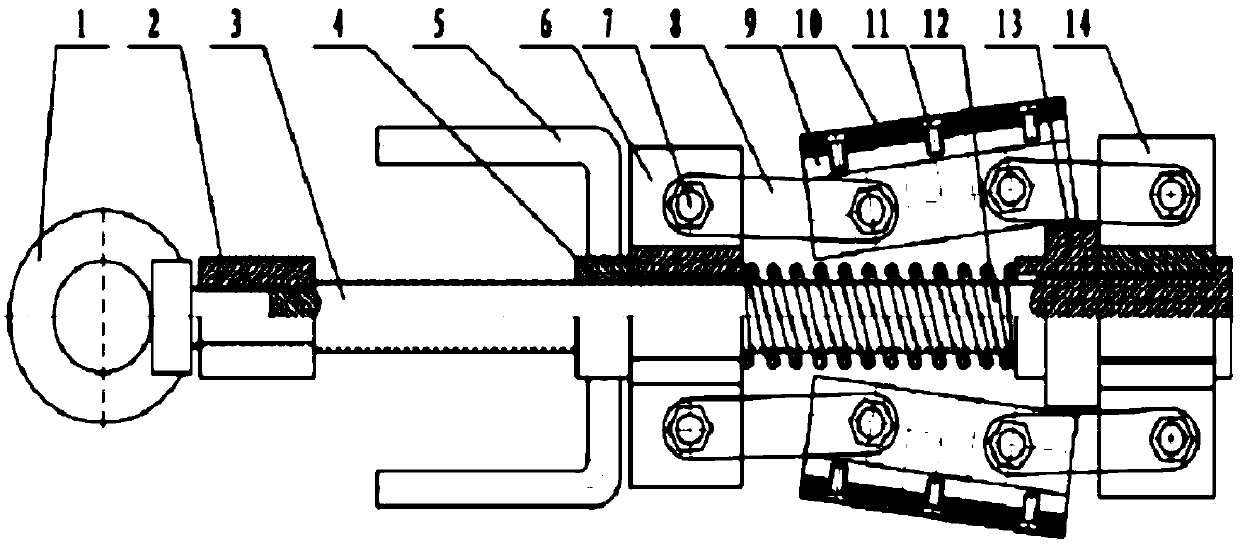

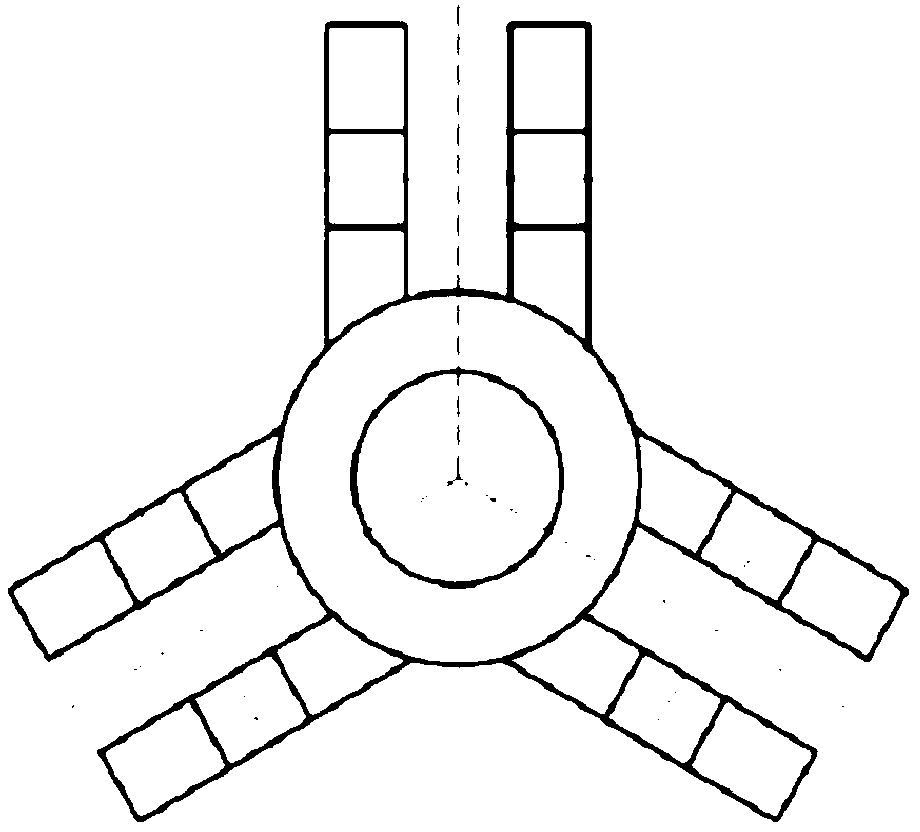

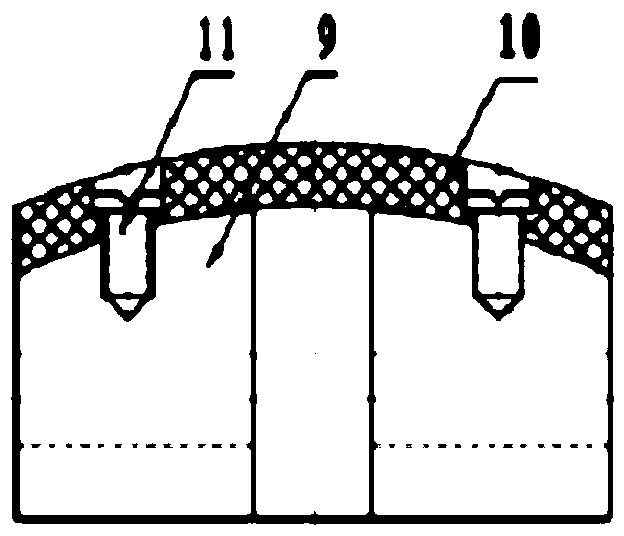

[0017] During specific implementation, a stator winding hoisting device includes a lifting ring 1, a connector 2, a screw rod 3, a nut 4, a nut handle 5, an upper connecting piece bracket 6, a bolt 7, a connecting piece 8, an expansion block 9, an anti-skid plate 10, Screw 11, compression spring 12, spring seat 13, lower link bracket 14.

[0018] The suspension ring 1 and the screw rod 2 are integrally formed through a connector 3 . The nut handle 5 is installed on the screw rod 3 through the nut 4 . The upper connecting piece support 6 and the lower connecting piece support 14 are installed on the screw rod 3, the lower connecting piece support 14 is fixed on the screw rod, the spring seat 13 is installed on the lower connecting piece support,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com