Insulation systems for tools and tools with insulation systems

A technology of insulation systems and tools, applied in the direction of insulators, insulators, manufacturing tools, etc., can solve the problems of inability to prevent voltage, expensive, prone to failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

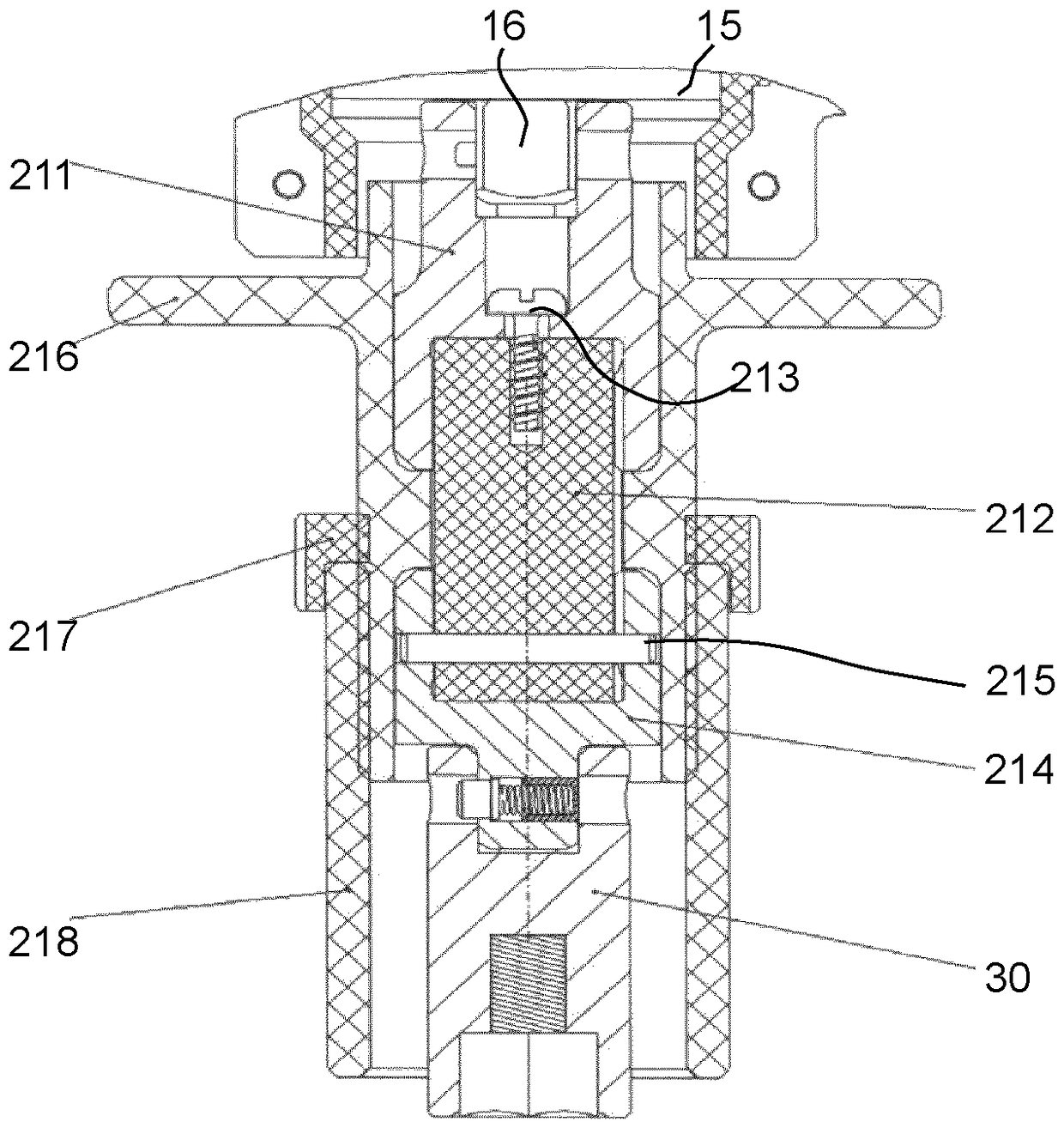

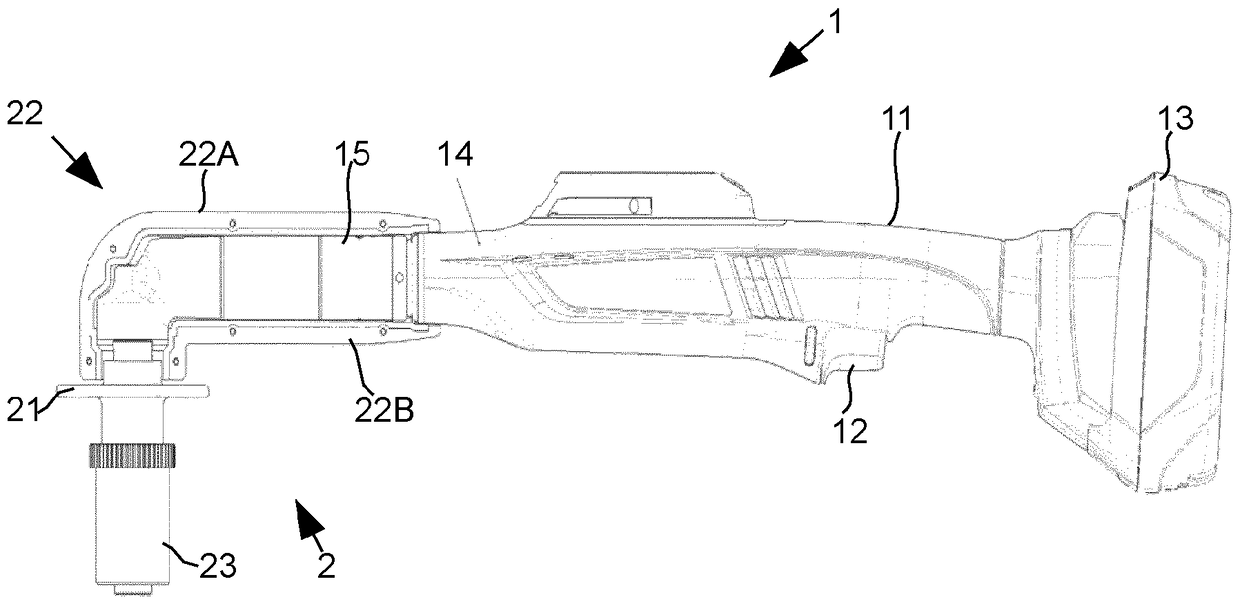

[0018] figure 1 A tool 1 with an insulation system 2 is shown. The tool 1 may be a screwing tool (screwdriver), a riveting tool, a punching tool, a bolt installation tool, and the like. figure 1 Tool 1 in is a tool that can be held in the hand. But Tool 1 is not limited to this. Tool 1 may also be a desktop tool.

[0019] exist figure 1 The middle tool 1 has a handle 11 , an on / off switch 12 , a battery holder 13 , a housing 14 and a drive unit 15 . Batteries, such as rechargeable accumulators or non-rechargeable batteries, can be accommodated in the battery compartment 13 . The tool 1 is thus a cable-free tool. The casing 13 is made of a material such as plastic or the like, which functions as electrical insulation. The tool 1 thus has a surface made of an electrically insulating material in the region of the housing 13 . However, the tool 1 has a metal housing, in particular a steel housing, on the drive unit 15 . The drive unit 15 therefore has an electrically cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com