Production distribution scheduling method based on ant colony algorithm

A scheduling method, ant colony technology, applied in the field of supply chain, can solve problems such as not considering the total cost of production and distribution, and not being able to adapt to production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

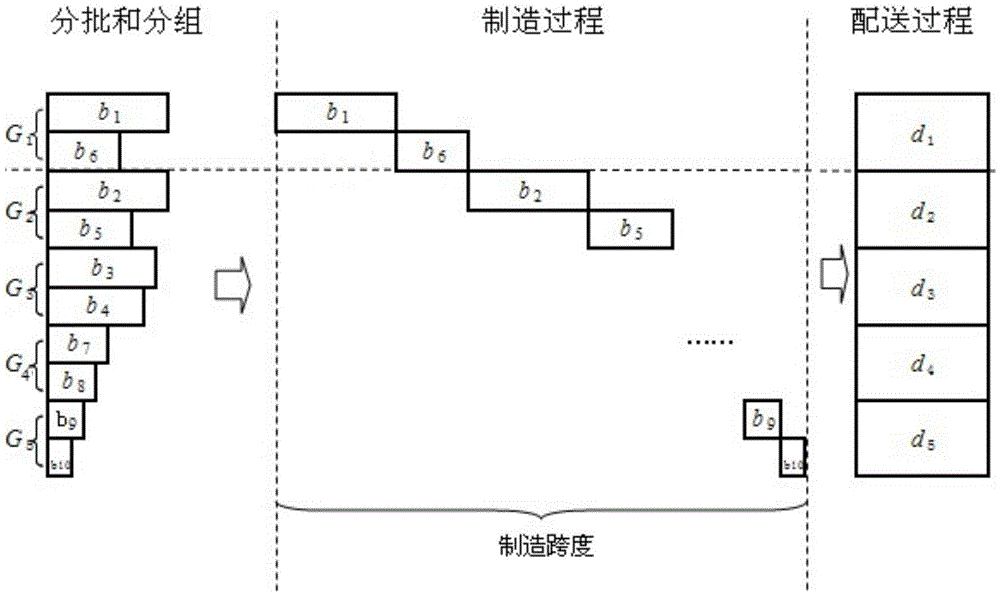

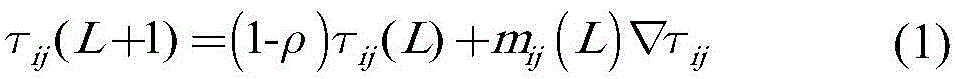

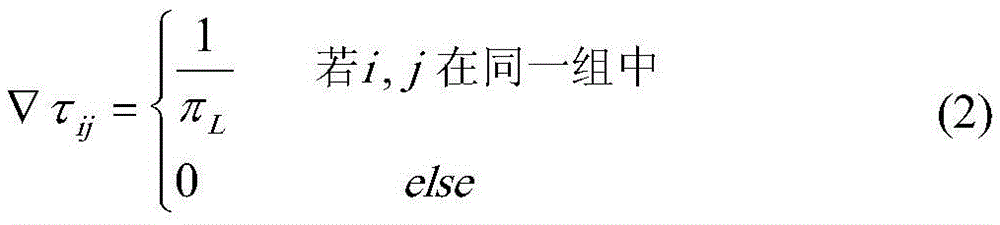

[0053] In this embodiment, a production and distribution scheduling method based on ant colony optimization is to model the production and distribution joint scheduling problem with differences in volume and production time, and then solve it through an improved ant colony algorithm to obtain a set of The optimization plan of production and distribution scheduling, in order to greatly reduce the total operating cost of the target manufacturing enterprise and improve the operating efficiency of the enterprise; at the same time, a practical program development plan is given for specific problems, so that the enterprise can obtain the most suitable for it efficiently. Optimal scheduling scheme. Specifically, proceed as follows:

[0054] Step 1. Assuming that there are n batches that need to be produced and distributed, the volume of equipment for producing each batch is recorded as B; the volume of vehicles for delivering each batch is recorded as V; n batches form a batch set, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com