Pneumatic punching machine capable of being used for plates with different thicknesses

A pneumatic punching and plate technology, applied in the direction of perforating tools, metal processing, metal processing equipment, etc., can solve the problems of low production efficiency and achieve the effects of prolonging service life, convenient use and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0024] The invention will be described in detail below with reference to the accompanying drawings and examples.

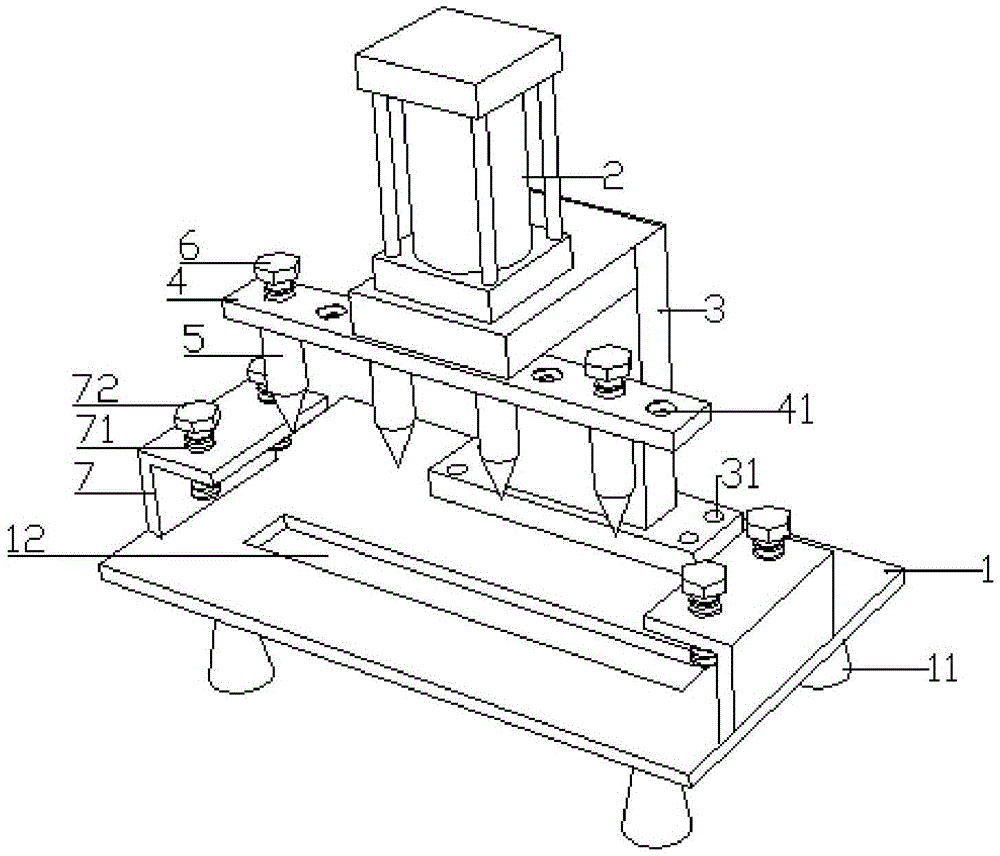

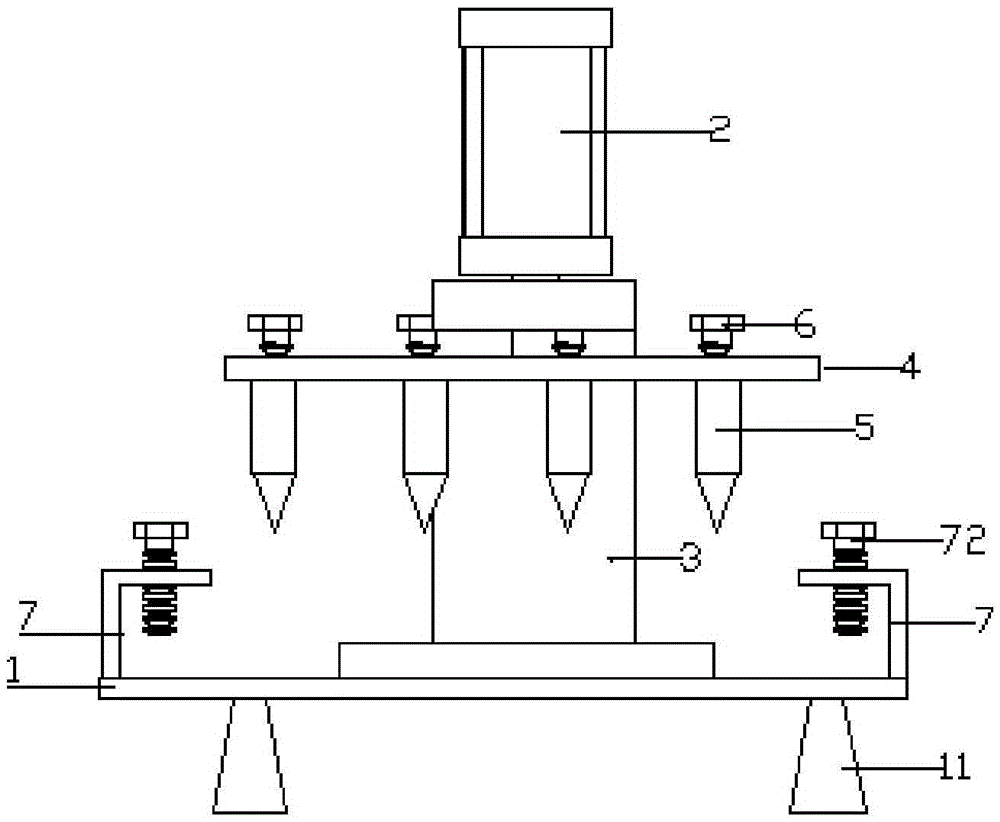

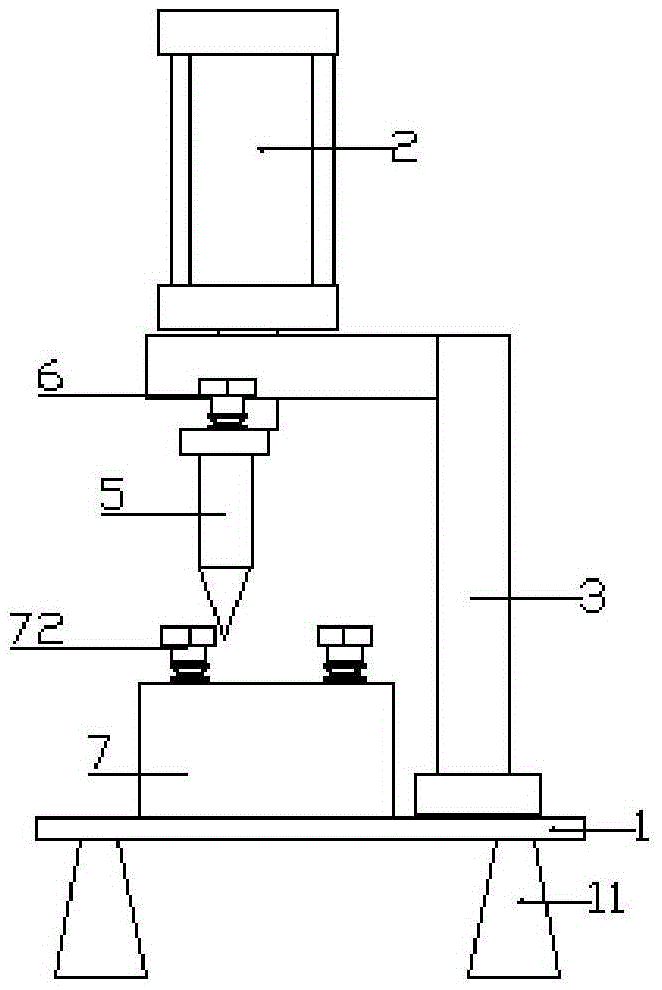

[0025] A pneumatic punching machine that can be used for plates of different thicknesses, including a platform 1, a leg 11 is provided under the platform 1, and a cylinder seat 3 is provided on the platform 1, and the cylinder seat 3 is connected to the said platform through the screw hole b31 The platform 1 is fixedly connected, the cylinder base 3 is an inverted L shape, the horizontal part of the cylinder base 3 is fixed with a cylinder 2, and the output end of the cylinder 2 passes through the horizontal part of the cylinder base 3, the The output end of the cylinder 2 is fixed with a punch frame 4, the punch frame 4 is provided with a punch 5, the inside of the punch 5 is provided with an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com